Thin pipe cutting device

A cutting device and thin tube technology, applied in the field of mechanical processing, can solve the problems of difficult to guarantee cutting accuracy and thin tube deformation, and achieve the effect of ensuring quality and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

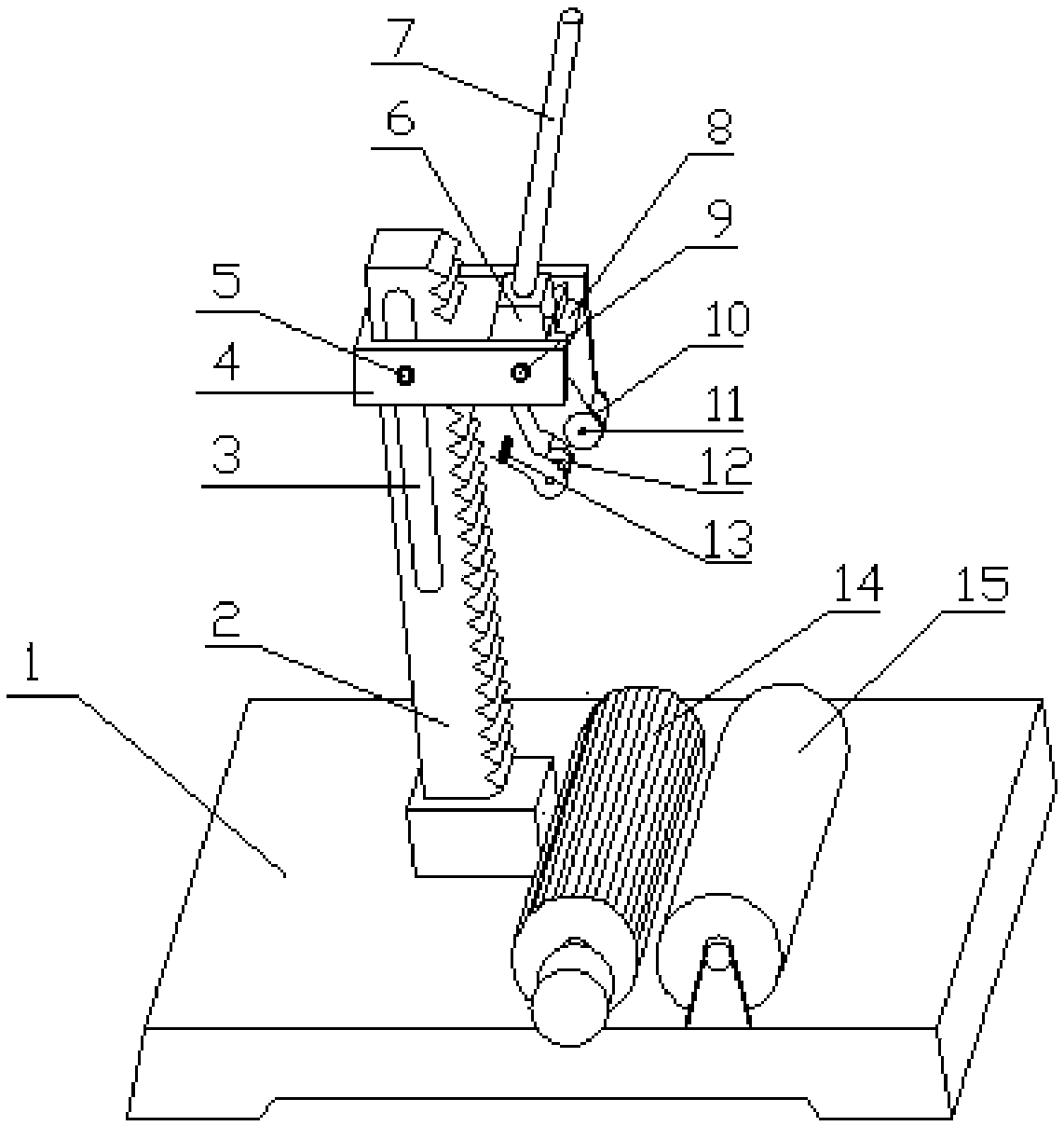

[0023] figure 1 Among them, the driving roller 14 and the driven roller 15 form the bearing part, and other parts form the cutting part, and these two parts are installed in the vicinity of the base 1;

[0024] The active roller is connected to the power transmission mechanism, which can be a motor or a combination of a motor and a transmission system (not shown in the figure), to drive the active roller to rotate;

[0025] The driving roller 14 and the driven roller 15 are horizontally installed on the base, and there is a gap suitable for placing the pipe to be cut between the driving roller and the driven roller;

[0026] The surface of the active roller 14 is covered with a rubber layer, and the rubber layer is provided with a grid to increase the surface friction, which is beneficial to drive the pipe to be cut to rotate;

[0027] The rack 2 is installed vertically on the base and is located on the side of the tube, and the tooth surface of the rack 2 faces the direction...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap