Subway electric power maintenance workbench convenient to maintain

A technology for electrical maintenance and workbenches, applied in workbenches, manufacturing tools, workshop equipment, etc., can solve the problems of not having parts grinding, not having the function of parts cleaning, and inconvenient parts drilling, etc. Function, increase cleaning effect, easy adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

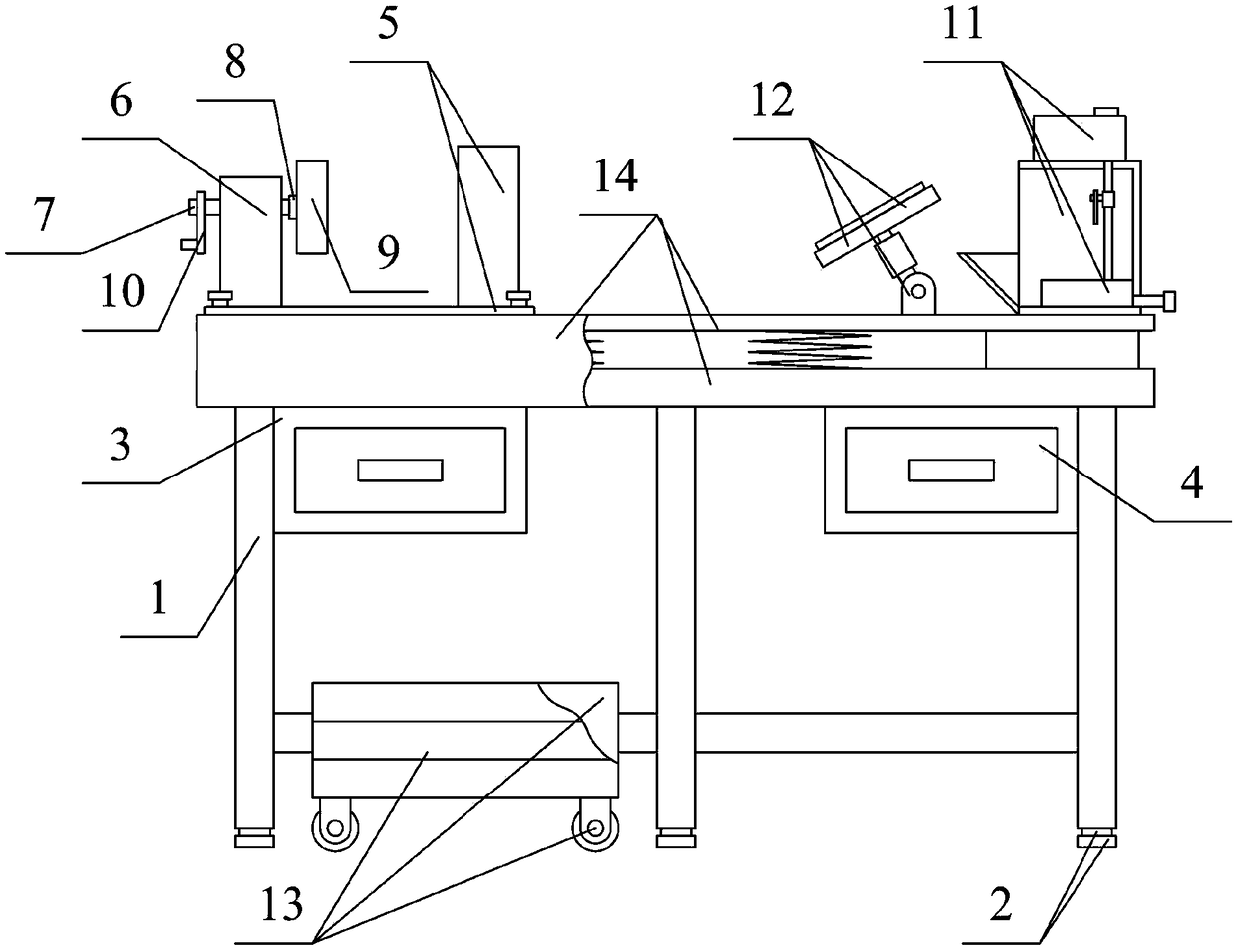

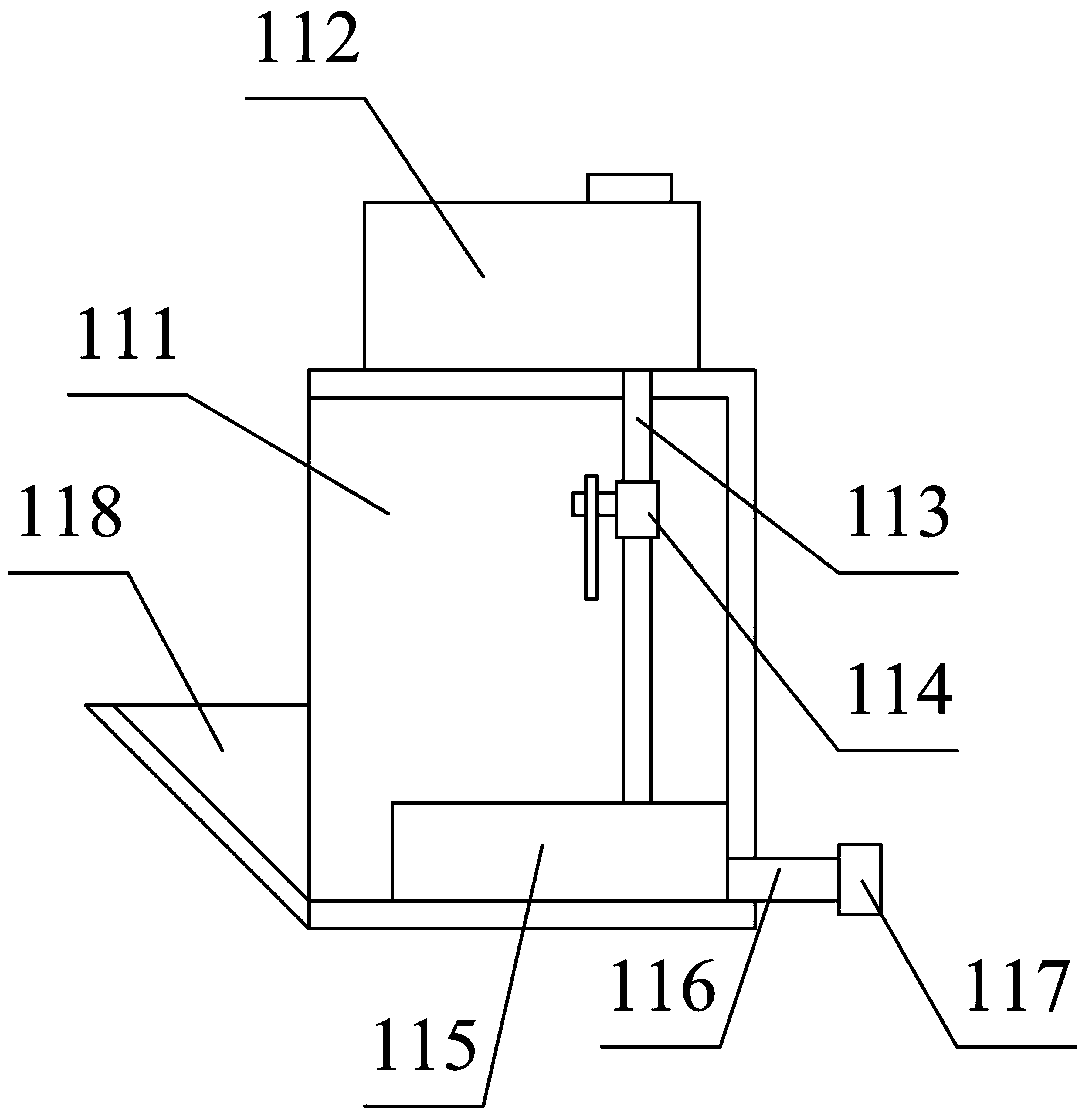

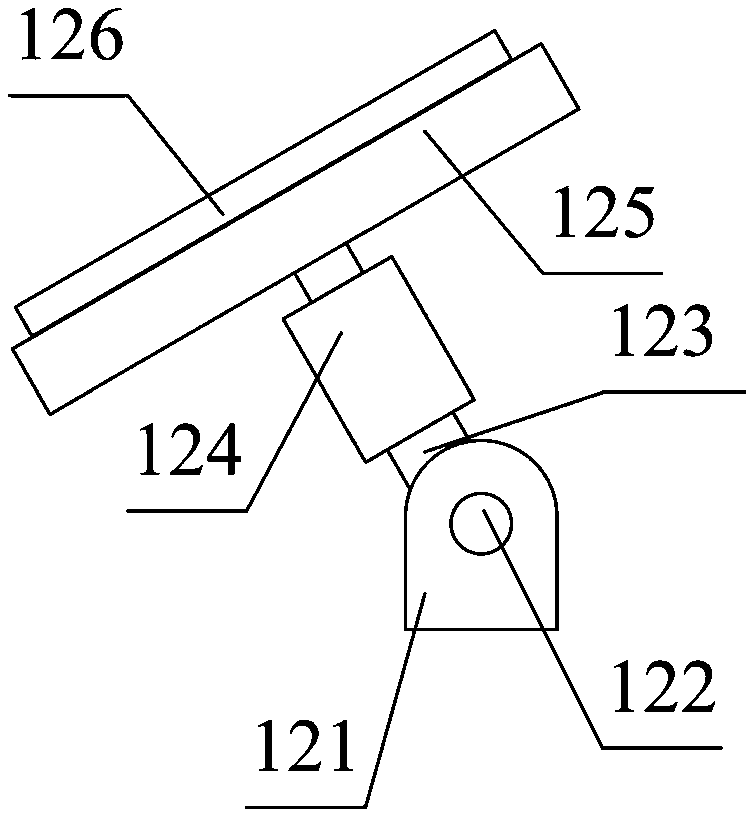

[0039] as attached figure 1 And attached figure 2As shown, a maintenance-friendly subway power maintenance workbench includes a support frame 1, an anti-skid seat 2, a plug-in case 3, a plug-in box 4, a fixed top seat 5, a fastening block 6, a threaded rod 7, and a bearing 8. Tightening plate 9, rotating handle 10, cleaning box structure 11, processing and polishing disc structure 12, supporting stand structure 13 and decompression plate structure 14, and the anti-slip seat 2 is screwed to the lower end of the support frame 1 respectively, and at the same time The upper end of the support frame 1 is equipped with a decompression plate structure 14; the anti-slip seat 2 is specifically made of a rubber seat, thereby avoiding the problem of easy movement; the socket shell 3 is respectively welded on the left and right sides of the inner wall of the support frame 1 , and a plug-in box 4 is plugged into the front surface inside the plug-in shell 3, which can play a storage tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com