Parallel-series mixing device with four branched chains driving single branch chain for servo

A four-chain, follow-up technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of weak resistance to deformation under constant external load, increased difficulty in operation and control, and increased structural complexity, so as to reduce the occurrence of Possibility of singularity, effect of increased safety and reliability, increased load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings.

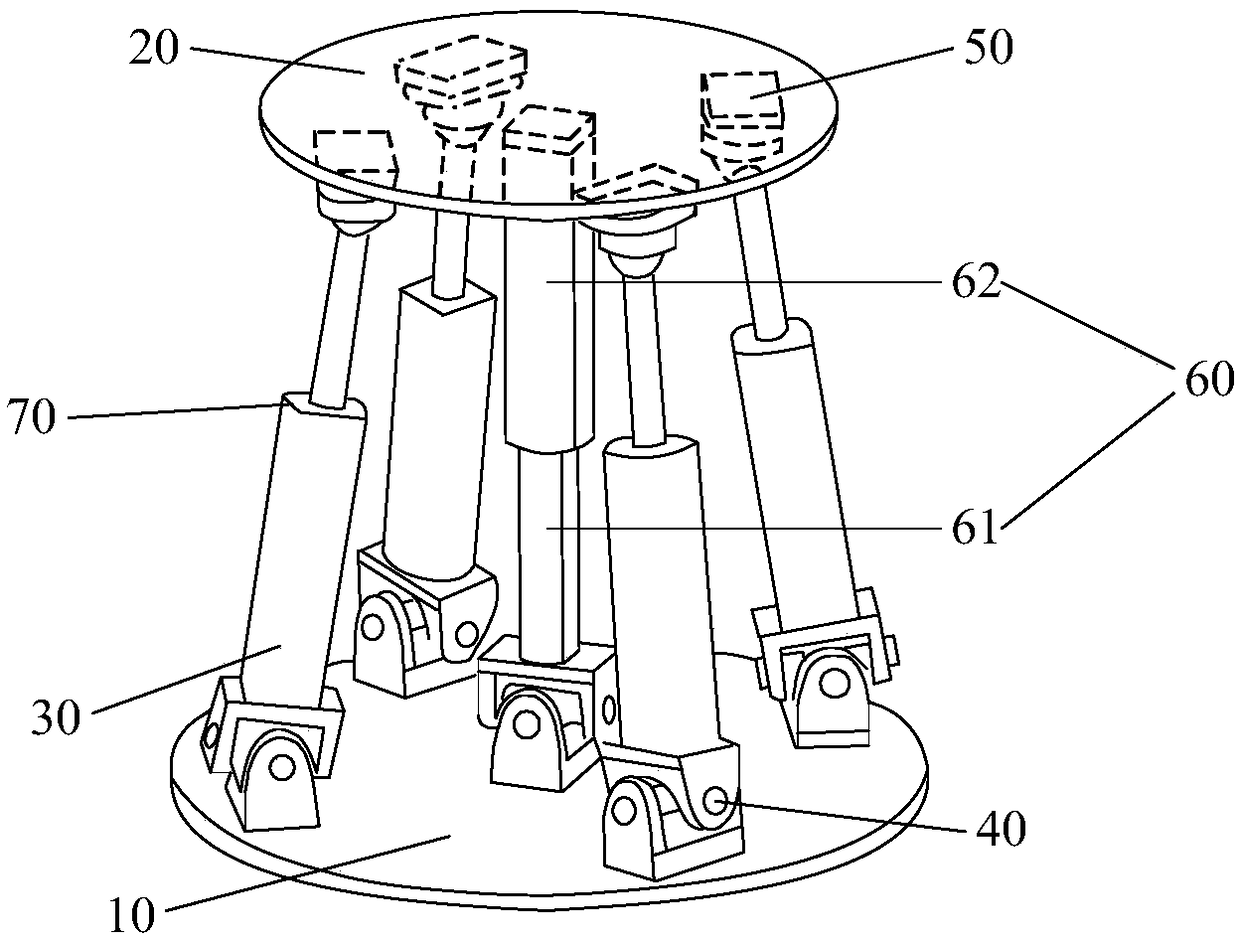

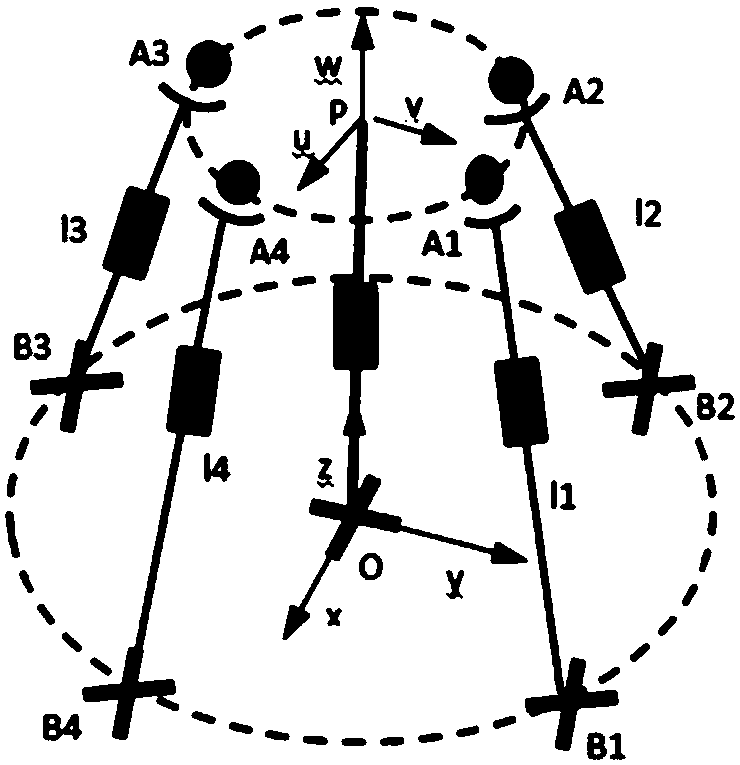

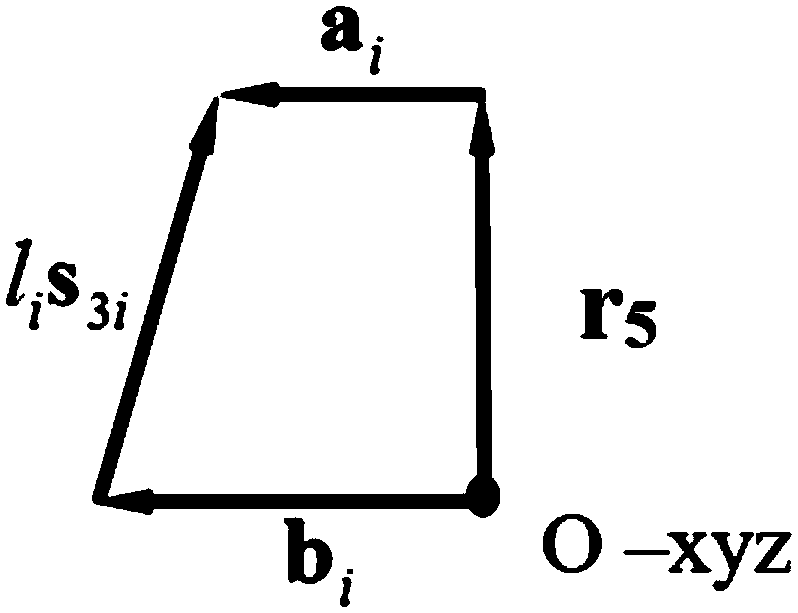

[0025] A parallel-series hybrid device with four-chain driven single-chain follower, including a base 10, a moving platform 20, an electric cylinder 30, a cross hinge 40, a ball hinge 50, and a follow-up branch 60. The lower ends are respectively connected with the upper surface of the base 10 through the cross hinges 40 , the upper ends of the electric cylinders 30 are respectively connected with the lower surface of the movable platform 20 through the ball hinges 50 , and the lower ends of the follower chain 60 are connected through the cross hinges 40 . It is connected with the middle of the base 10, and the upper end of the follow-up branch 60 is connected with the lower surface of the moving platform 20. The moving platform 20 has two degrees of freedom of rotation and one degree of freedom of lifting. Rotation of direction and lifting within a certain range.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com