Micro battery sealing and explosion-preventing structure and inner pressure detecting method

A technology of miniature battery and explosion-proof structure, which is applied in the direction of lithium battery, structural parts, battery pack parts, etc., can solve the problems of hidden danger of battery and the inability to detect internal pressure of the battery, so as to improve the safety of use, take up less space, and improve the performance of the battery. Effects of rigidity and structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

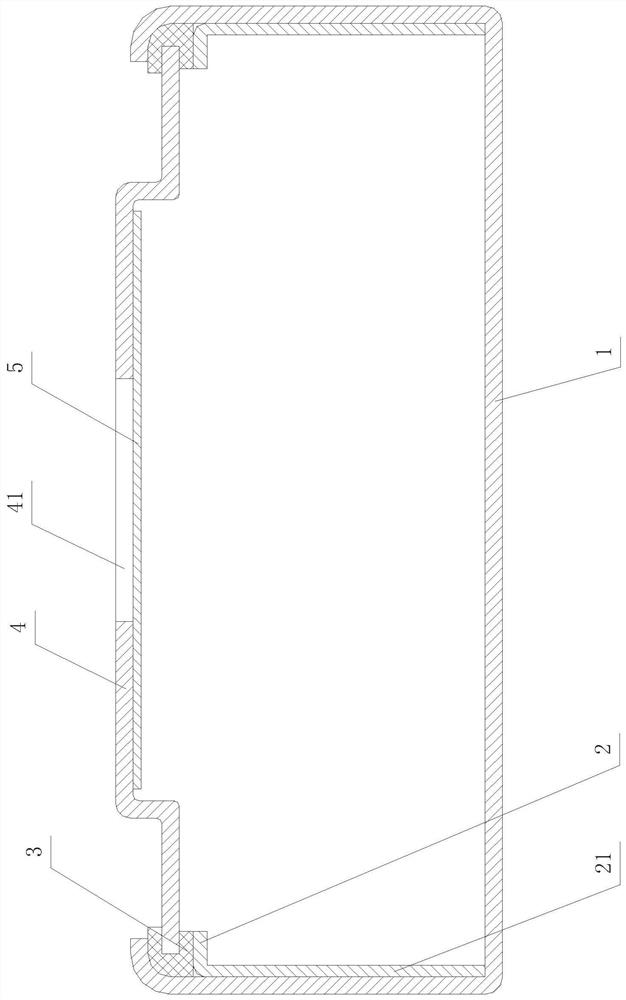

[0033] Embodiment one, refer to figure 1 , in this embodiment, it includes a casing 1 with an open upper end, which is a cylindrical structure, and an installation cavity for installing a battery assembly is provided in the casing, and the upper end of the installation cavity forms a seal for installing a sealing assembly. In the seal installation area, a seal assembly is installed in the seal installation area. The seal assembly includes a support ring 2, a seal ring 3 and a cover body. The edge of the support ring 2 is bent downward to form a support part 21. The outer wall of the support part 21 is attached to the inner wall of the housing, and the lower end of the support part 21 is in contact with the bottom surface of the installation cavity to realize the shaft Orientation, a seal ring 3 is provided on the upper end of the support ring, and an annular groove with an opening inward (towards the axis of the housing) is provided on the seal ring—the annular groove is suppo...

Embodiment 2

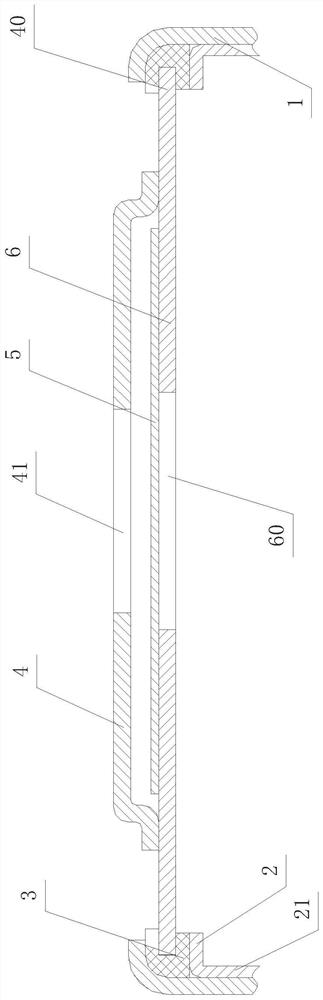

[0034] Embodiment two, refer to figure 2, which is different from Embodiment 1 in that the cover body includes an upper cover body 4 and a lower cover body 5, the upper cover body is located at the upper end of the lower cover body, and the edges of the upper cover body and the lower cover body are located at the edge of the sealing ring In the annular groove, an exhaust port 41 is provided on the upper cover, an explosion-proof hole 60 is provided on the lower cover, and an explosion-proof membrane 5 that can cover the explosion-proof hole is sealed and bonded on the upper surface of the lower cover; in this embodiment Among them, the battery assembly is connected to the lower surface of the lower cover (top cover) through wires, and the connection position is relatively large; the overall explosion-proof effect is good.

Embodiment 3

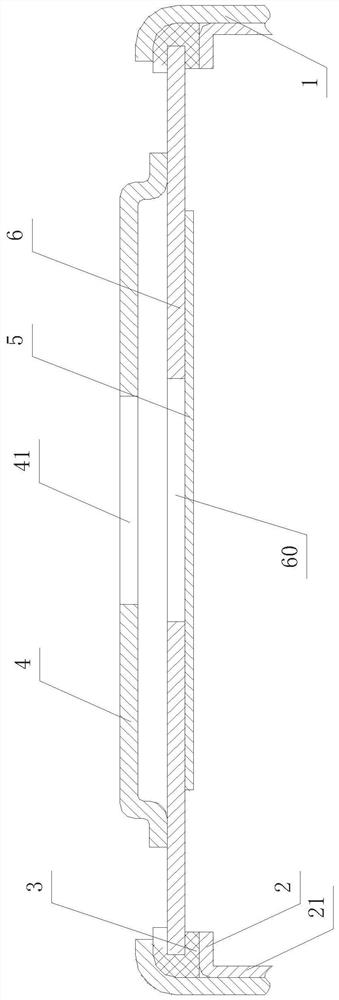

[0035] Embodiment three, refer to image 3 , which is different from Embodiment 2 in that the explosion-proof membrane is arranged on the lower surface of the lower cover.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com