Implantation method of z-pin large thickness

A z-pin, 1.z-pin technology, applied in the field of variable density prefabricated body structure and ultrasonic-assisted layer-by-layer implantation, can solve the problems that cannot match the application requirements of large-thickness composite materials, Z-pin bending instability, and reinforcing fiber Low axial modulus and other problems, to improve the implant angle accuracy, improve stability, and achieve the effect of interlayer enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

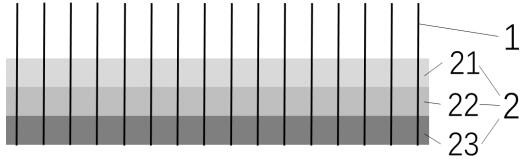

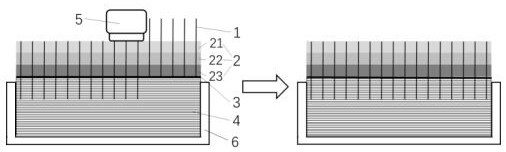

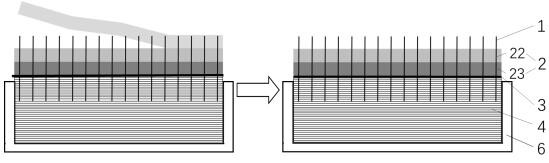

[0036] The Z-pin variable density preform of this embodiment includes a large-thickness preform carrier 2 and Z-pin1, wherein: the large-thickness preform carrier 2 is composed of multiple layers of foam layers detachably superimposed and fixed together, and the foam The layer density gradually increases from top to bottom. The Z-pin1 is implanted in the large-thickness prefabricated body carrier 2, and the Z-pin1 penetrates the multi-layer foam layer up and down. When the Z-pin1 is implanted into the prepreg blank 4, The lower surface of the large-thickness preform carrier 2 is in contact with the prepreg blank 4 .

[0037] In this embodiment, the application of the Z-pin three-dimensional reinforcement technology of the present invention to a large-thickness heat-resistant component is taken as an example for further detailed description.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com