Efficient producing drying device for assembling type building

A technology for drying equipment and construction, which is applied in the field of high-efficiency production and drying equipment for prefabricated buildings, which can solve problems such as wasting time and low efficiency, and achieve the effects of uniform drying, improved efficiency, and accelerated project progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

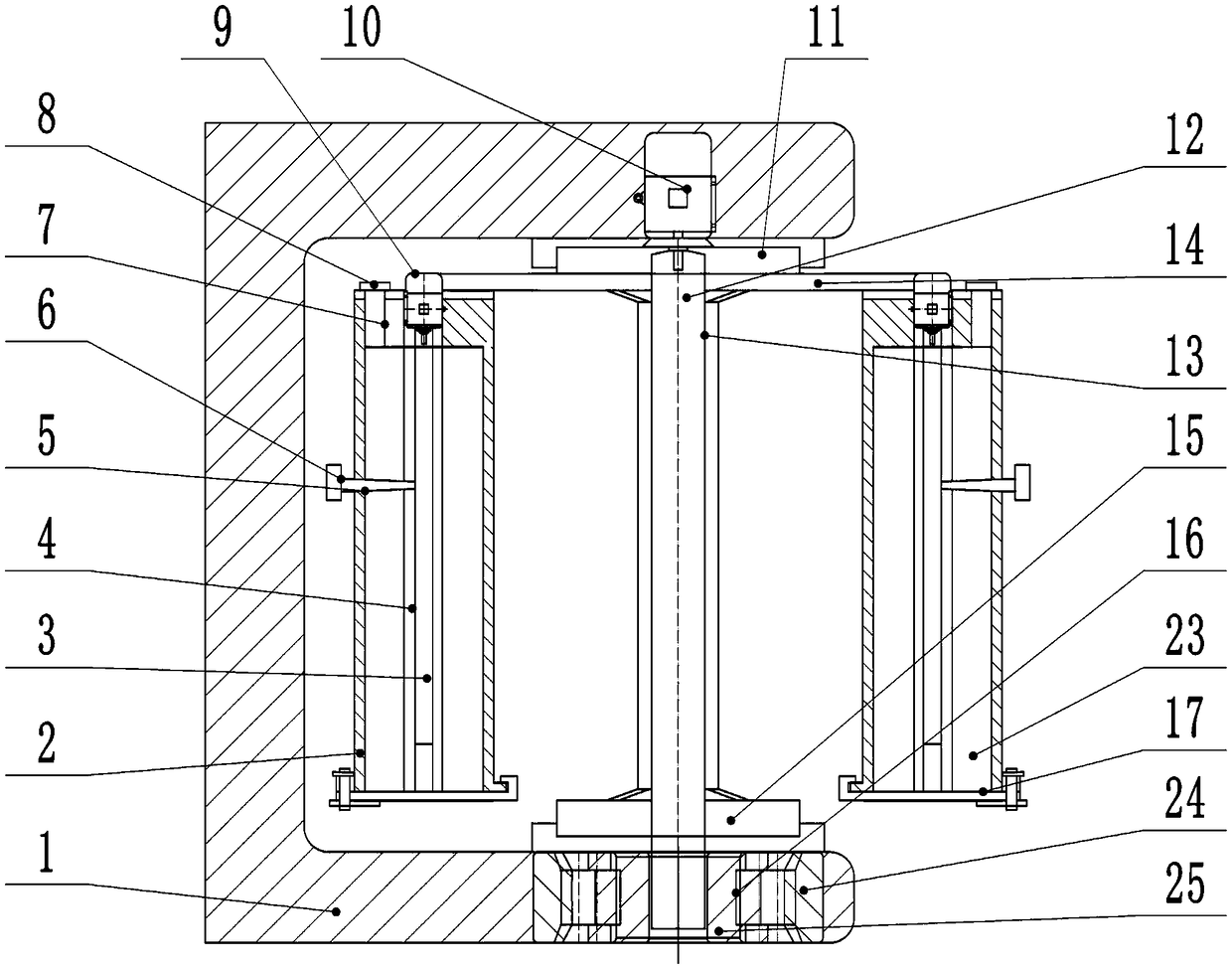

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

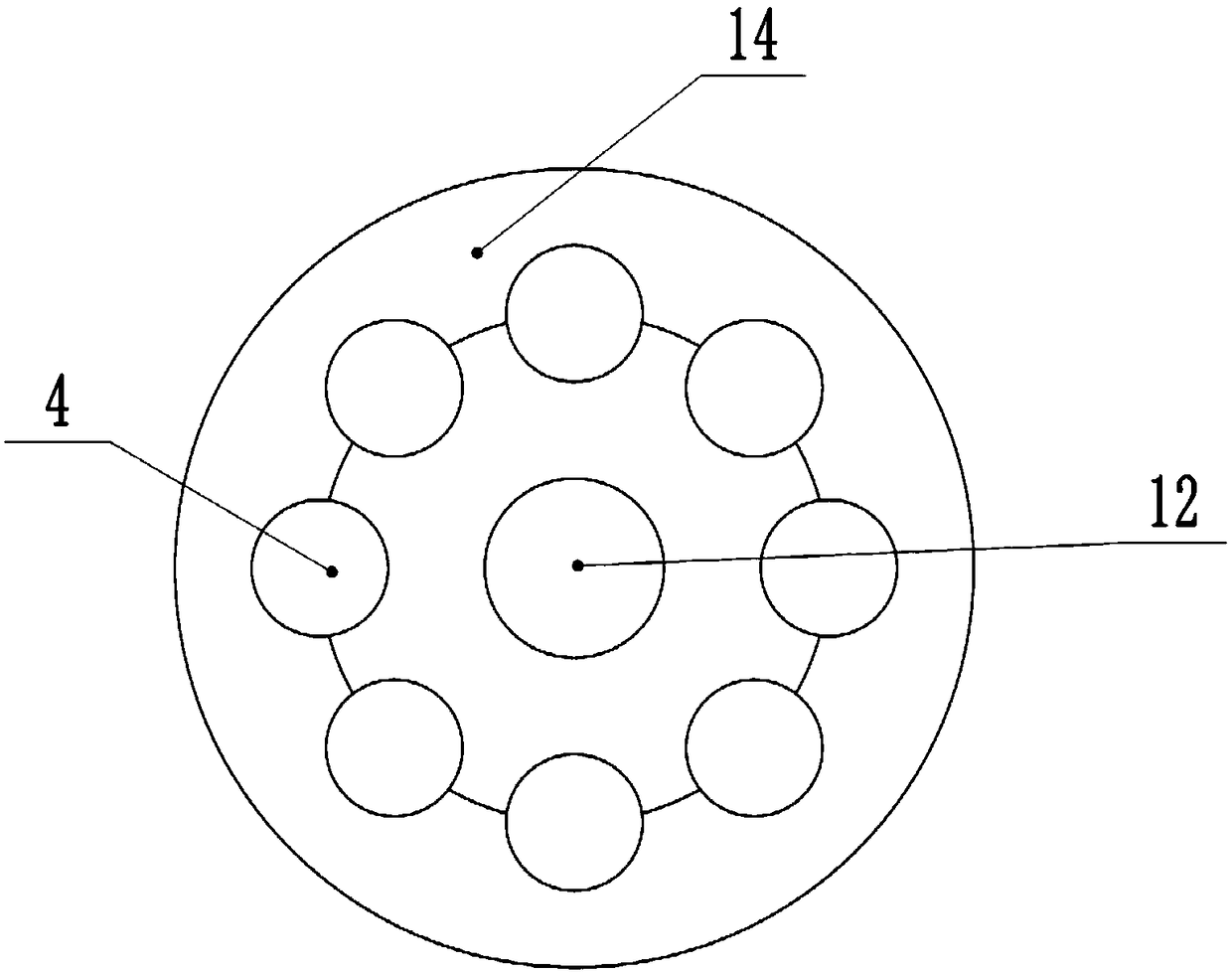

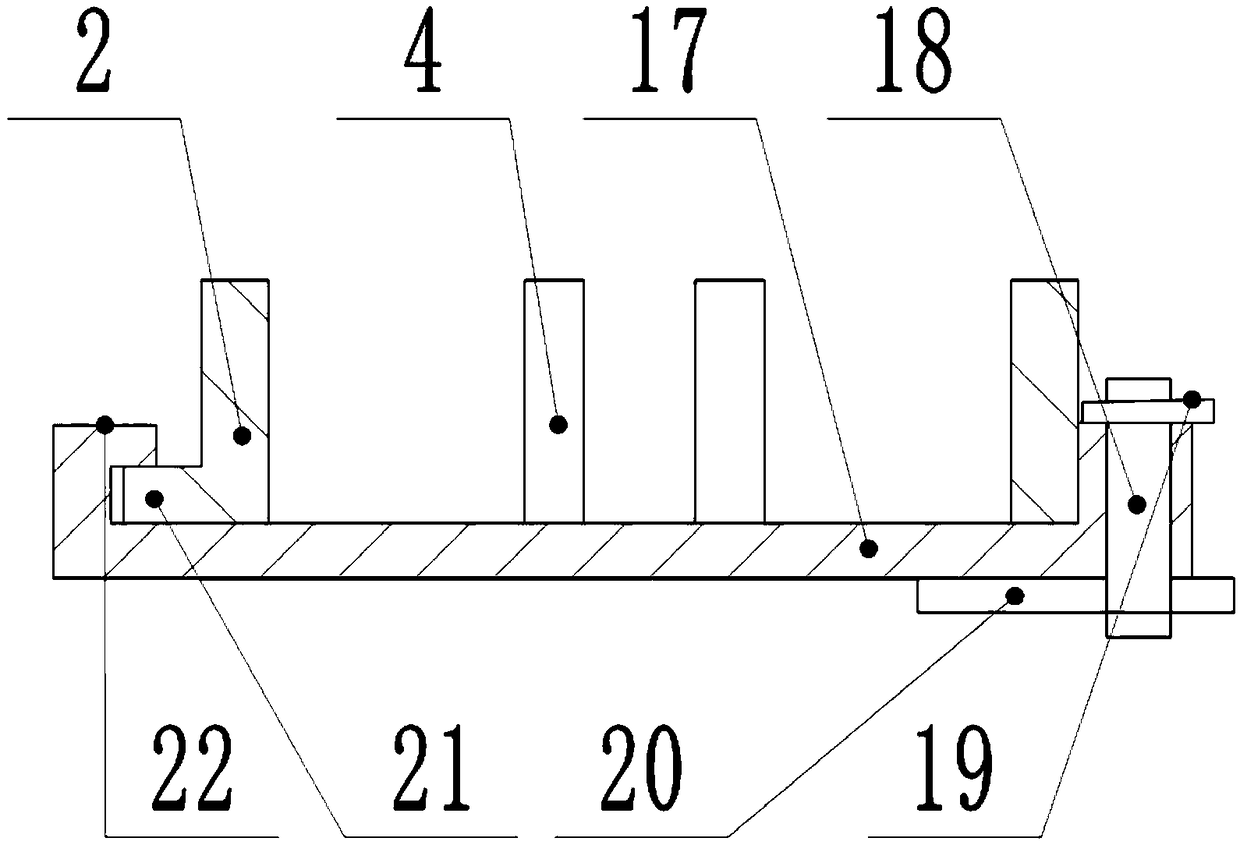

[0017] see Figure 1-3 , a kind of high-efficiency production drying equipment for prefabricated buildings, comprising: a support arm 1, a drying cabin shell 2, a connecting plate 14 and a lower baffle plate 17, the support arm 1 is fixedly installed on the ground, and the support arm 1 is made of steel plate Formed, semi-embracing structure, leaving a blanking channel on the right side, the first motor 10 is fixedly installed in the upper part of the support arm 1, and a rotating disc 11 is installed in the rotating connection below the outer side of the upper part of the supporting arm 1, and the lower part of the rotating disc 11 is fixedly connected There is a connecting plate 14, and the first rotating shaft 12 is fixedly connected coaxially under the first motor 10. The first rotating shaft 12 is made of bearing steel, and the surface is quen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com