Production process of novel high-performance bio-based textile material

A production process and bio-based technology, which is applied in textiles and papermaking, complete sets of equipment for the production of artificial threads, wet spinning, etc., can solve the problems of synchronous and coordinated control, separate control of spinning and coagulation liquid, etc., and achieve fast hardening, Precise year-on-year speed regulation and uniform fiber quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

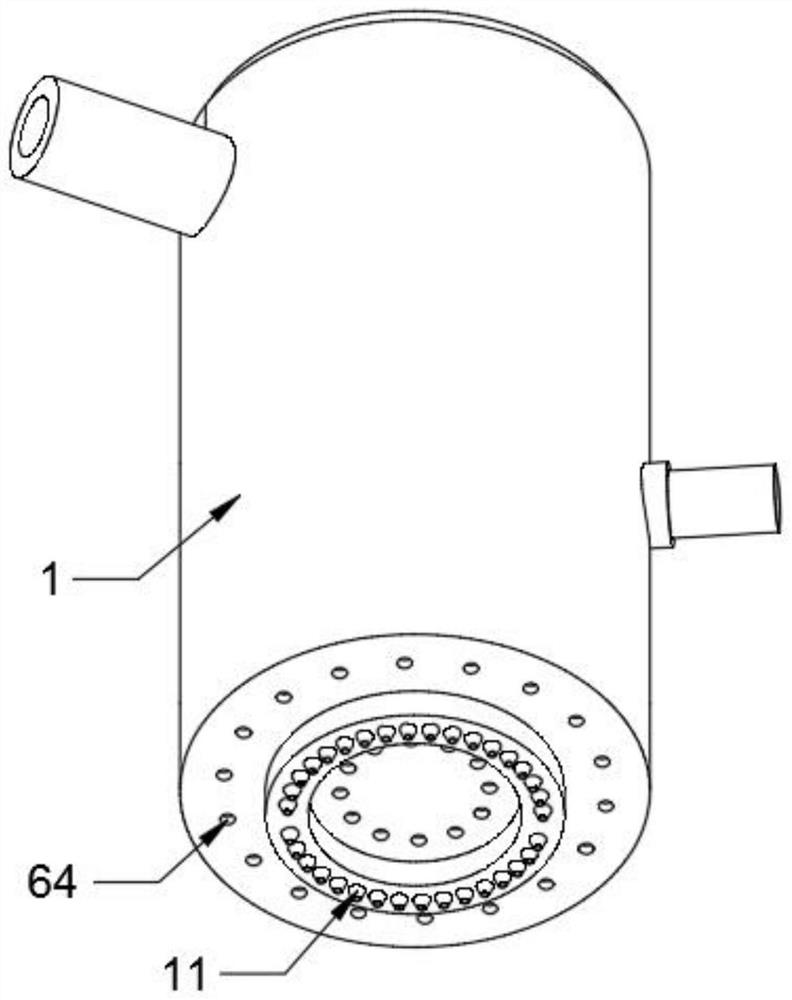

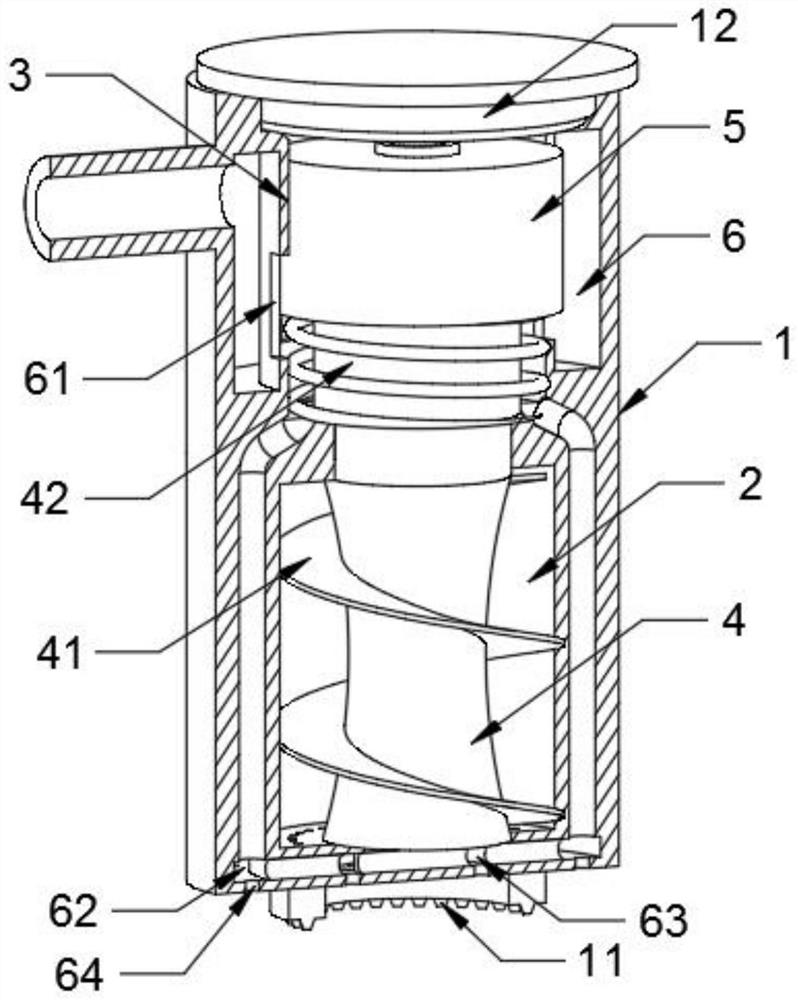

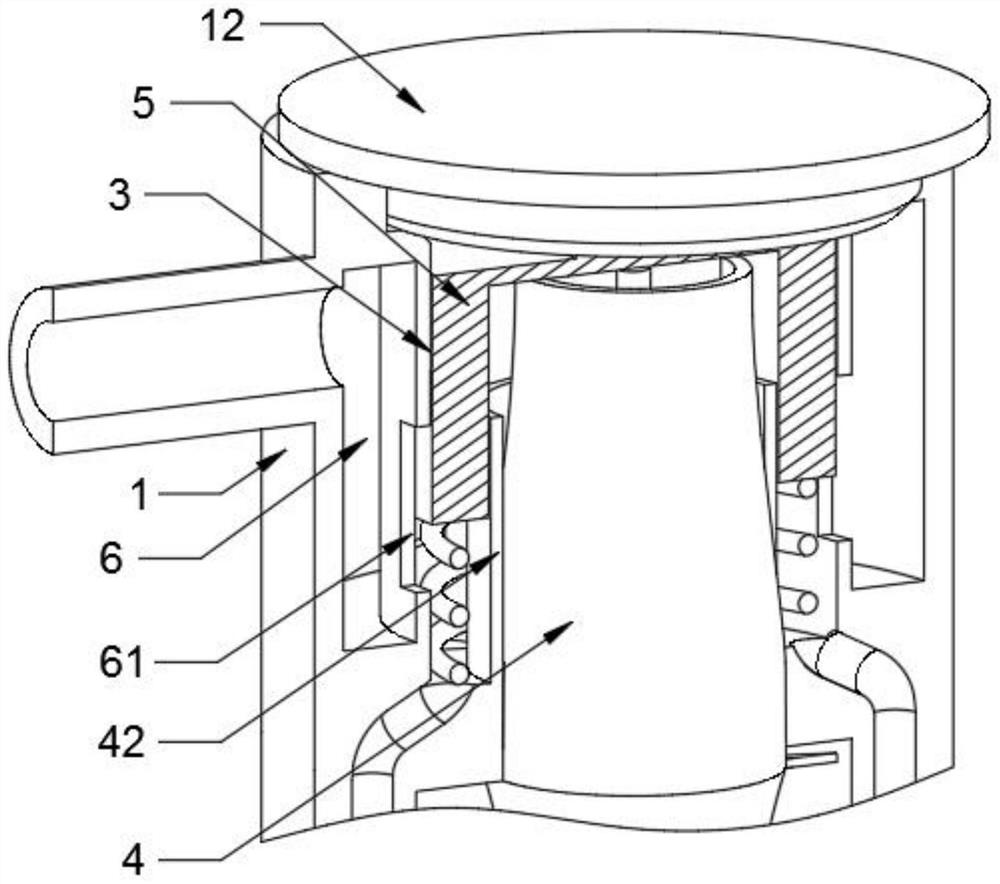

[0035] A production process of high-performance bio-based new textile materials, comprising the following steps:

[0036] A, select the sodium alginate solution with a concentration of 2wt%-3wt% to be introduced into the nozzle by pressurization and ejected from the spinneret hole 11, and the single-hole ejection speed of the sodium alginate solution is controlled to be 120ml / h-180ml / h;

[0037] b. The air bag 4 wrapped and contacted by the pressurized sodium alginate solution is arranged inside the nozzle, and the end of the air bag 4 detached from the wrap is a freely deformable end;

[0038] C, the flow path of discharging calcium chloride solution is set in the shower head, pressurizes and imports 30-50% (weight) calcium chloride solution in the flow path, and is sprayed by water spray hole 64;

[0039] d. Slidingly set the retaining ring 5 controlling the opening size of the flow channel in the calcium chloride solution flow channel, and the freely deformable end of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com