Steam evacuation in pulp or fiber refiner

A fiber separator and refining technology, applied in pulp beating/refining method, fiber raw material, fiber raw material processing and other directions, can solve the problems of uneven material flow, affecting the flow of fiber material, affecting the stability of the refining gap, etc. Achieve less fiber build-up, less turbulence and losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Throughout the drawings, the same reference numerals are used for similar or corresponding elements.

[0022] As mentioned in the background section, there is a continuing need in the art for further improvements in the removal of steam from the refining zone of a refiner.

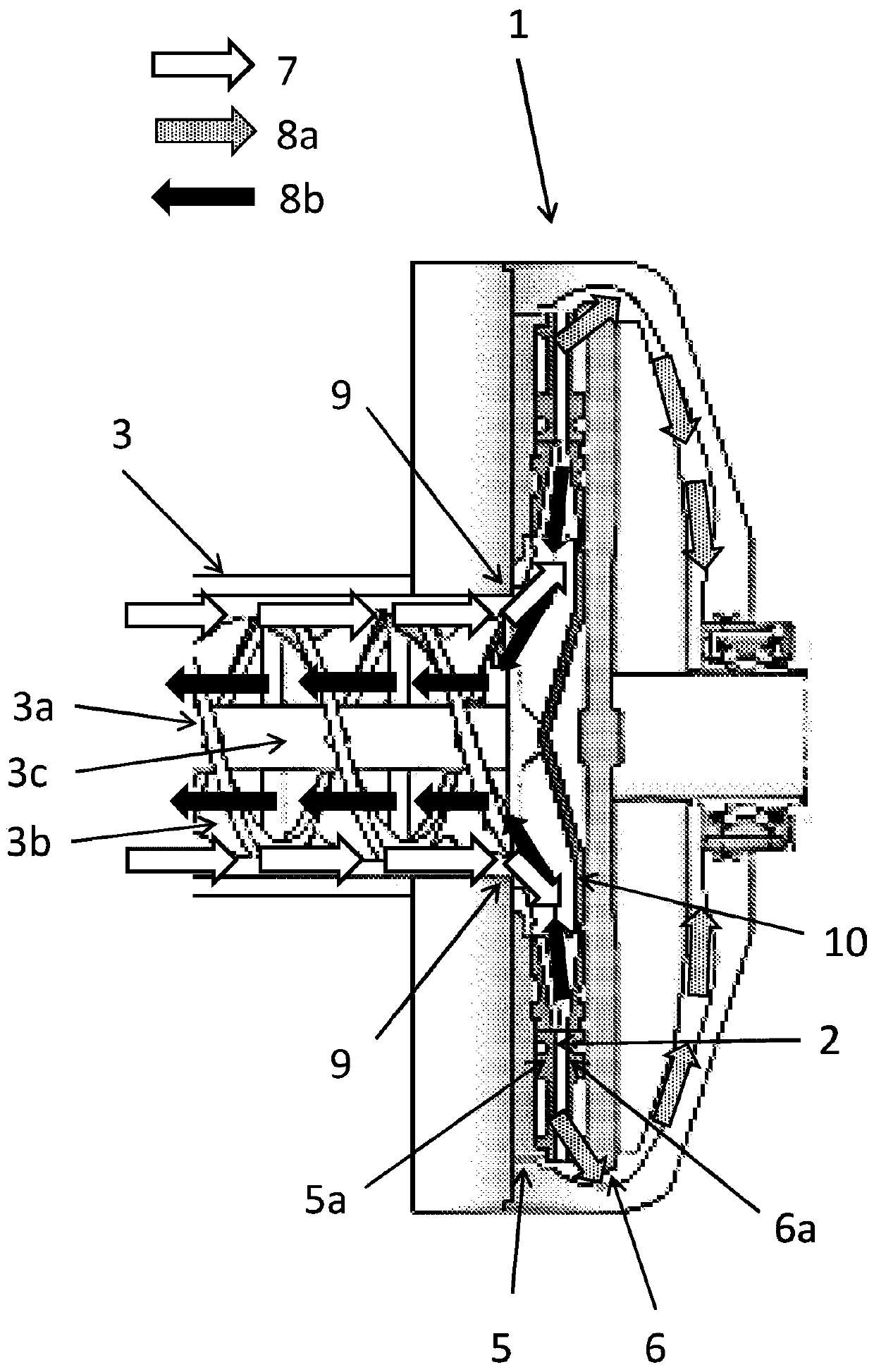

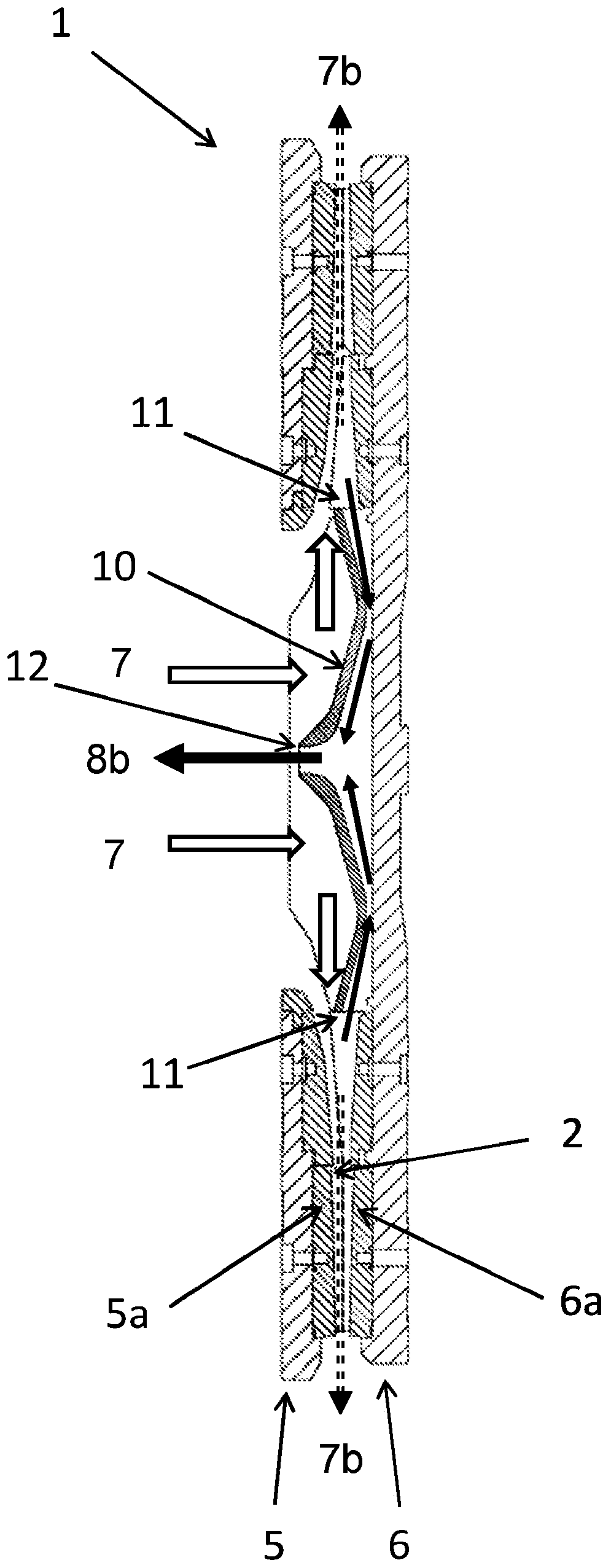

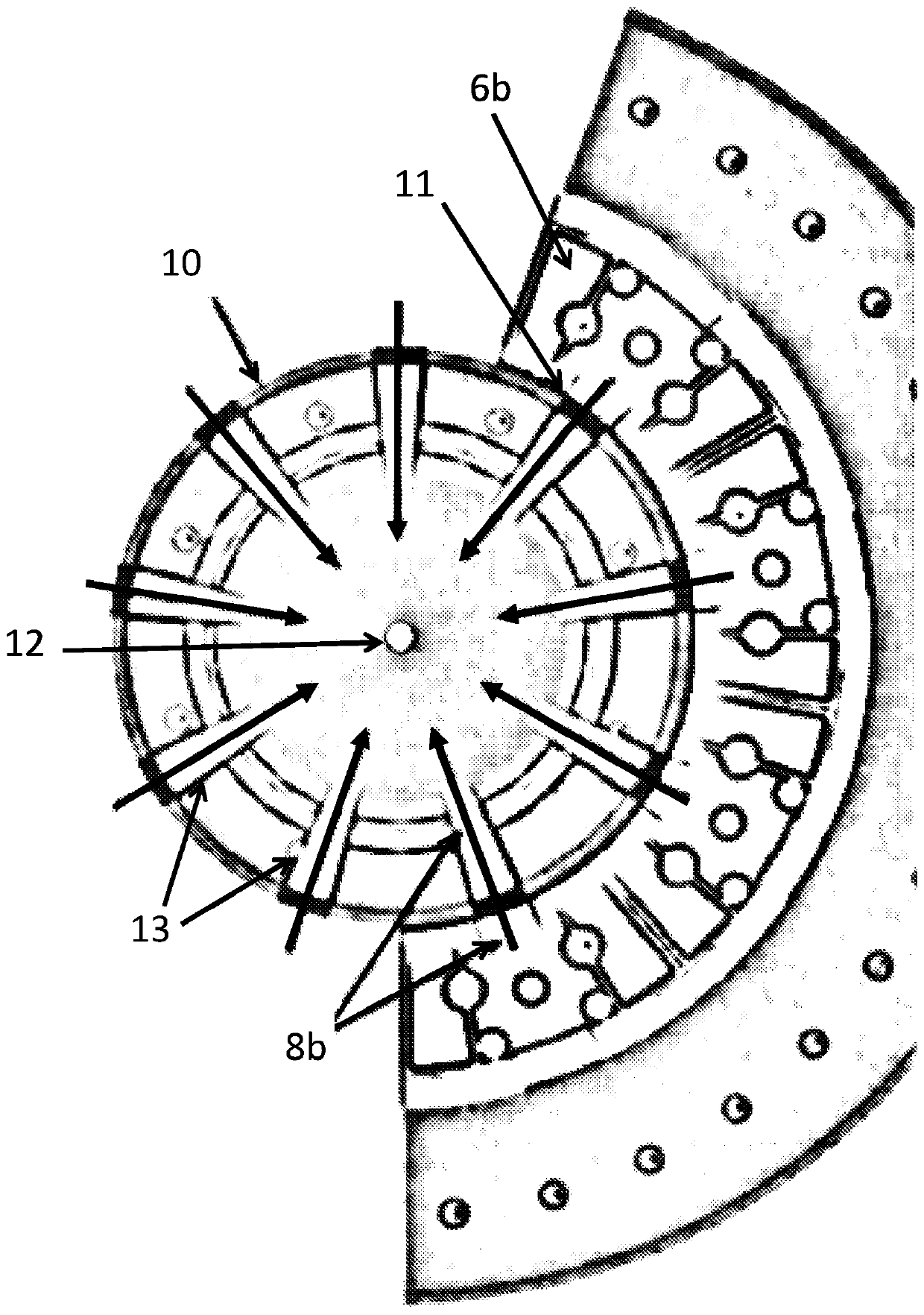

[0023] figure 1 is a schematic diagram of a typical defibrator arrangement in a pulp or fiber refiner. Here, a defibrator with a rotor and stator arrangement is described, but this embodiment can also be applied in a defibrator with two rotors. Lignocellulose-containing material 7, such as wood chips, is fed through a conveying screw / feed screw 3a, usually a belt feeder, via a feed channel 3 towards the defibrator 1 and through holes in the stator 5 into the refining disc, i.e. the stator 5 and the intermediate space between the rotor 6. The centrifugal force pushes the material towards the periphery of the refining disc to emerge in the refining gap / space 2 between the refining surfaces of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com