Single-column sodium silicate-bonded sand molding machine and molding technology thereof

A water glass sand and molding machine technology, applied in molding machines, manufacturing tools, casting and molding equipment, etc., can solve problems such as increased investment and inconvenient organization, and achieve the effects of increased labor productivity, low labor intensity, and simple process operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

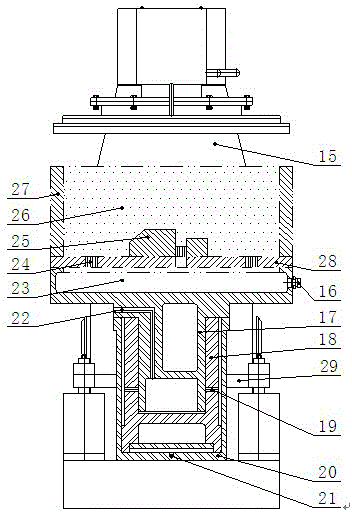

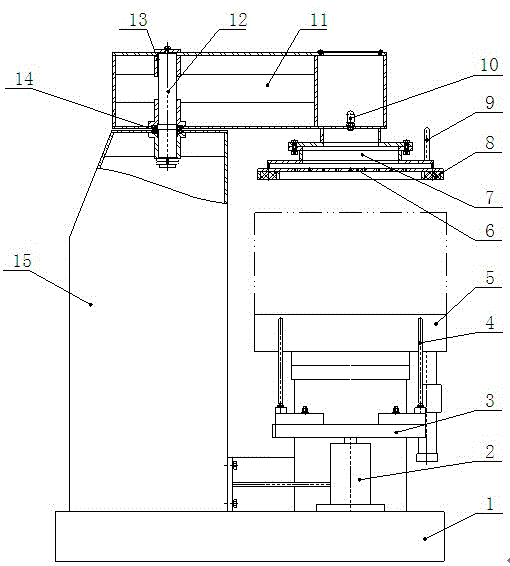

[0024] For traditional CO 2 The hardened water glass sand process has the problems of large amount of water glass added, unstable hardening process, prone to "overblown" phenomenon, poor collapsibility of old sand, and VRH process needs to set up a special hardening room and large investment in equipment. The present invention provides A suitable for CO 2 The single-column water glass sand molding machine of the hardened water glass sand process includes a base 1, a frame 15 arranged on the rear side of the base 1, a mold ejecting mechanism, a lifting mechanism and a vibration mechanism arranged on the base 1, and the frame 15 The upper end is provided with a rotary arm 11, and a workbench 5 is arranged above the vibrating mechanism. The upper surface of the workbench 5 is sunken inward to form a cavity. There is a vacuum chamber interface 16, and the vacuum chamber interface 16 is connected with the vacuum system through a vacuum valve, and the rotary arm 11 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com