A kind of mold and production equipment for fireworks cylinder body

A technology for forming molds and production equipment, which is applied in the direction of forming indenters, attack equipment, ceramic molding machines, etc., can solve the problems that affect the service life of the mold release mold, the wear of the mold is relatively serious, and the accuracy of the equipment is greatly affected. The product structure is evenly stressed, the production cycle is shortened, and the extrusion molding time is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

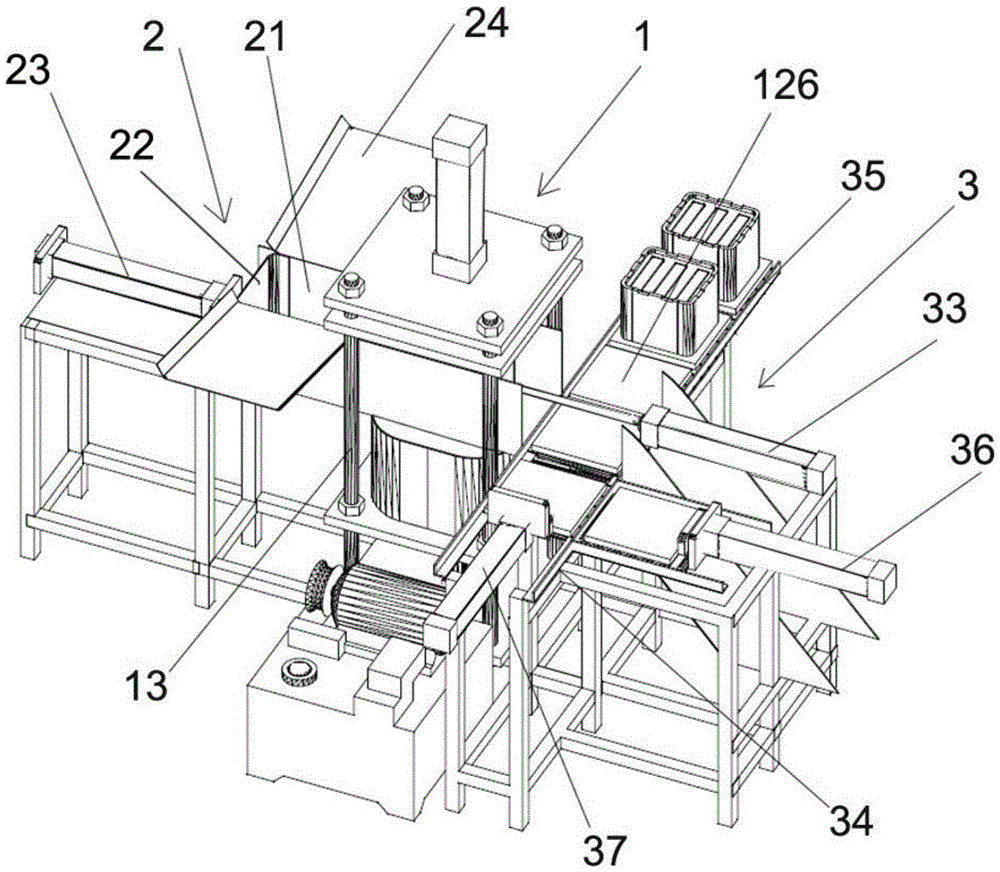

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

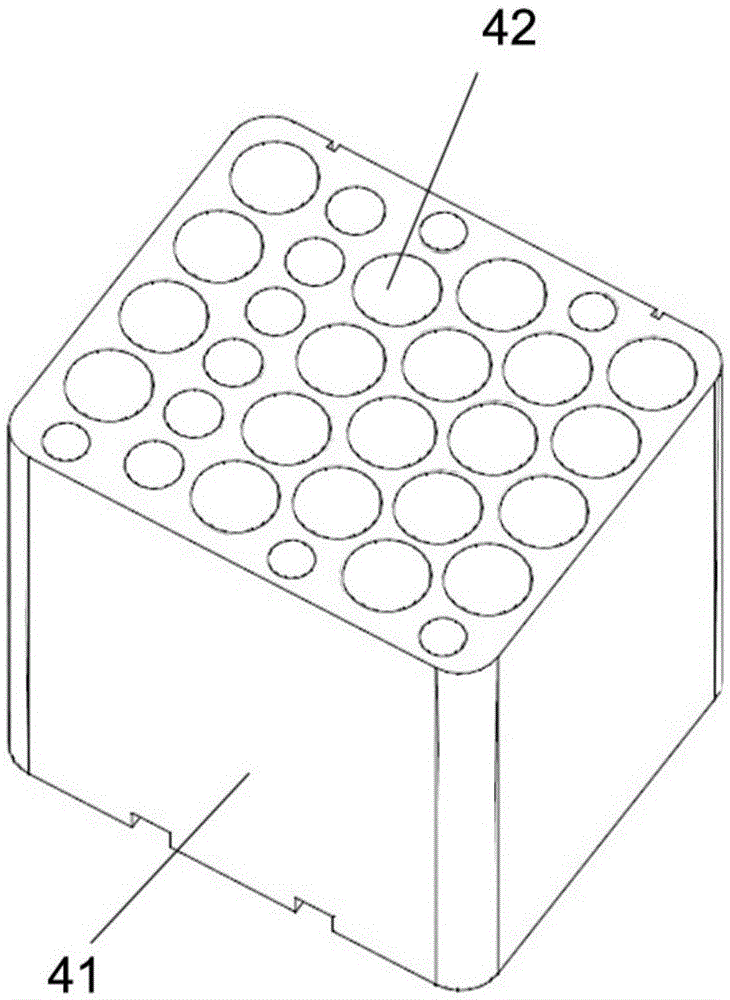

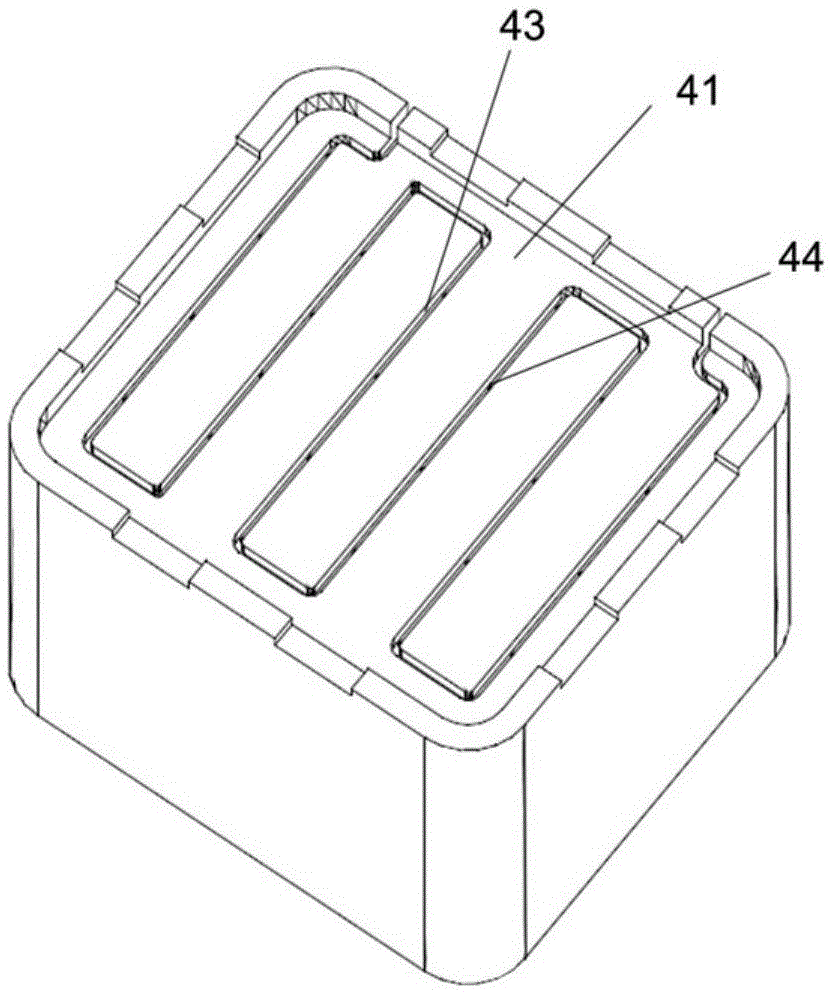

[0037] Such as figure 1 , figure 2 As shown, in this embodiment, the structure of the fireworks cylinder that needs to be molded is as follows: the fireworks cylinder includes a one-time extruded cylinder 41, an upwardly opened emission hole 42, and a lead groove arranged at the bottom of the cylinder 41. 43 and the lead hole 44 arranged on the lead groove 43 and connected to the emission hole 42 .

[0038] The body preparation method for preparing the above-mentioned fireworks tube in this embodiment includes the following steps:

[0039] a. Prepare raw materials, which include plant fibers, fillers and setting-hardening materials, wherein the setting-hardening materials use either air-setting cementitious mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com