Wedge-shaped magnetic material aligning and sorting device

A technology of magnetic material and material separation device, which is applied in the direction of conveyor control device, sorting, transportation and packaging, can solve the problems of low efficiency and quality inspection of wedge-shaped magnetic material sorting, and improve the sorting pass rate. , The effect of small overall footprint and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

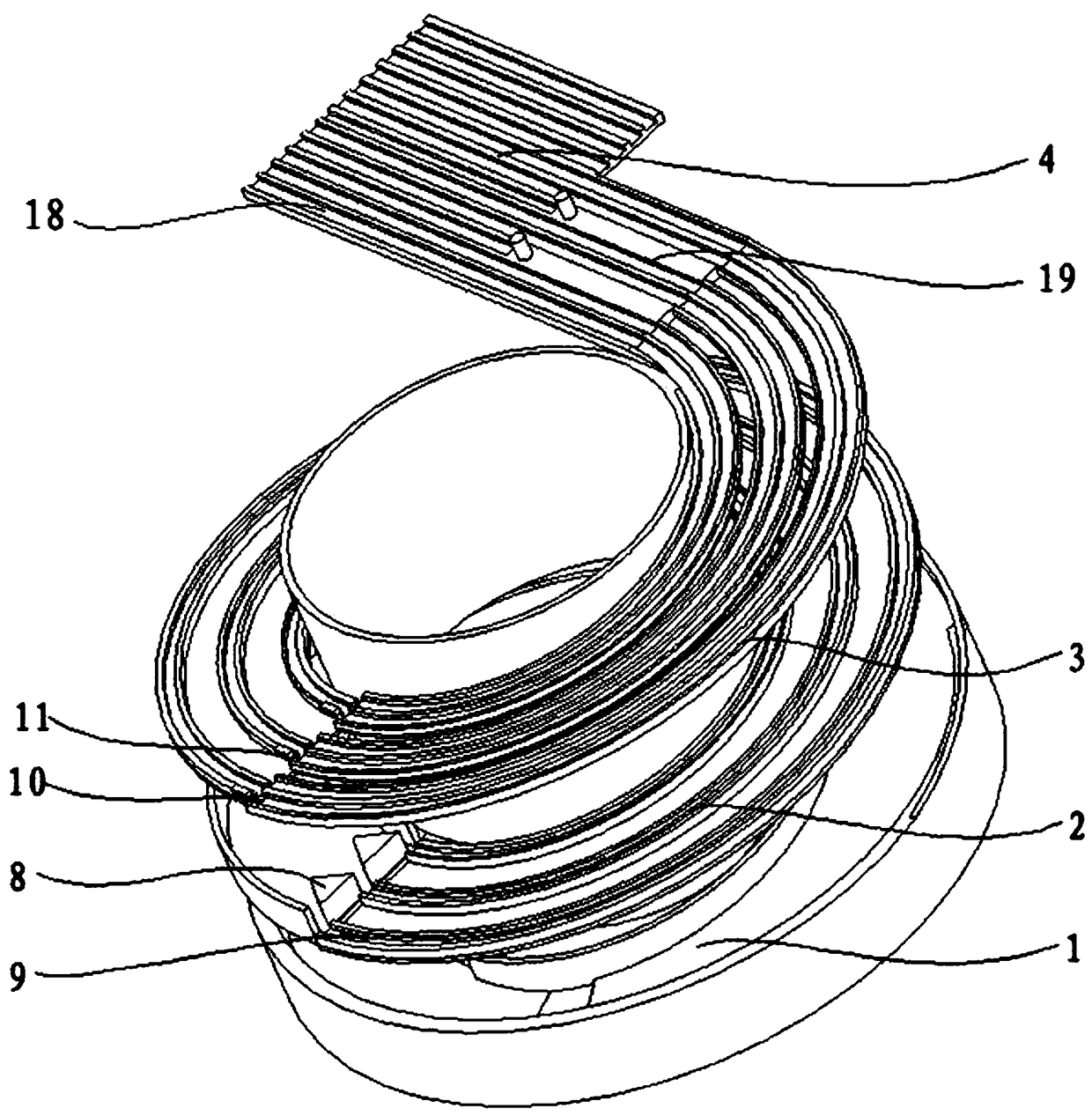

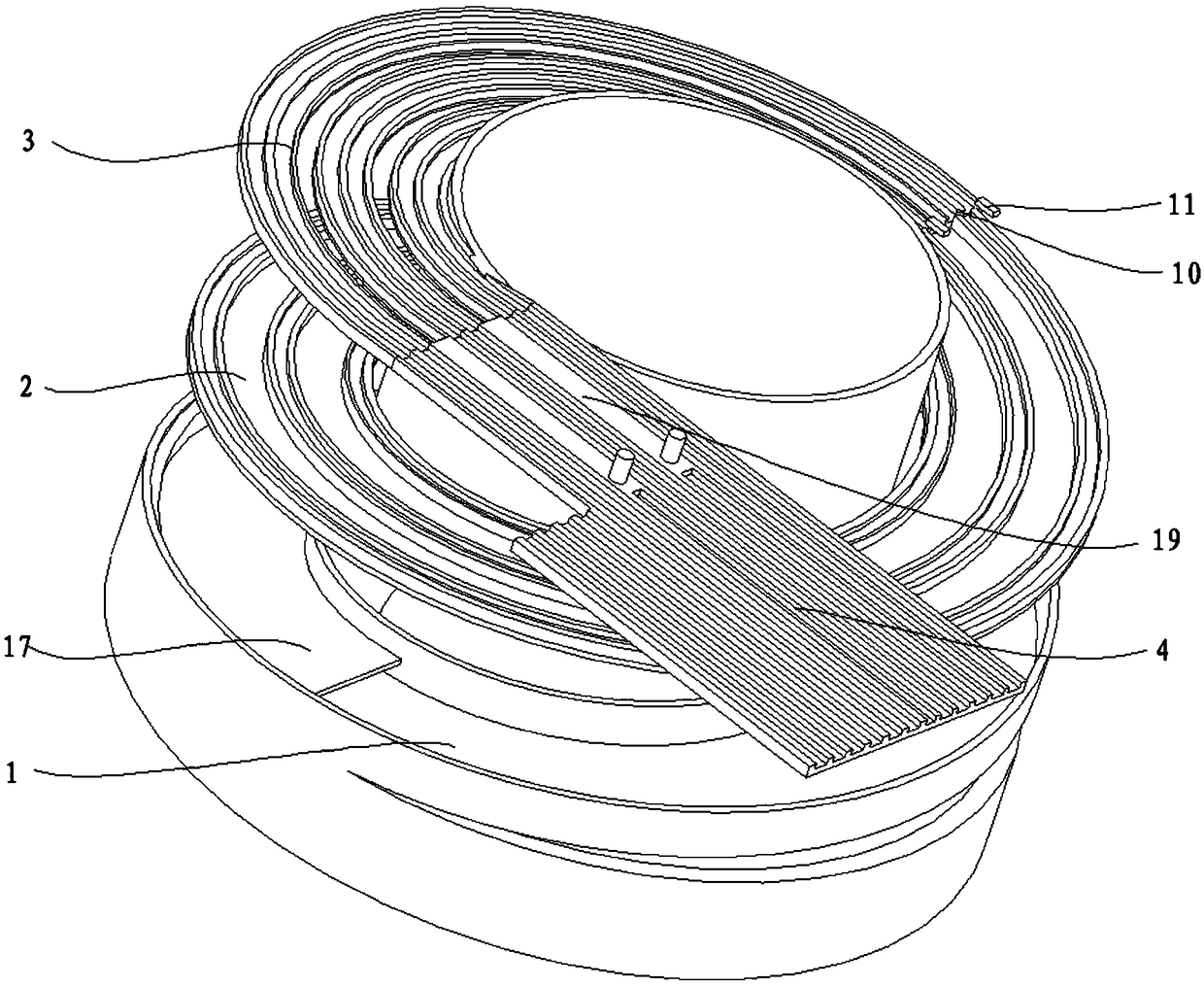

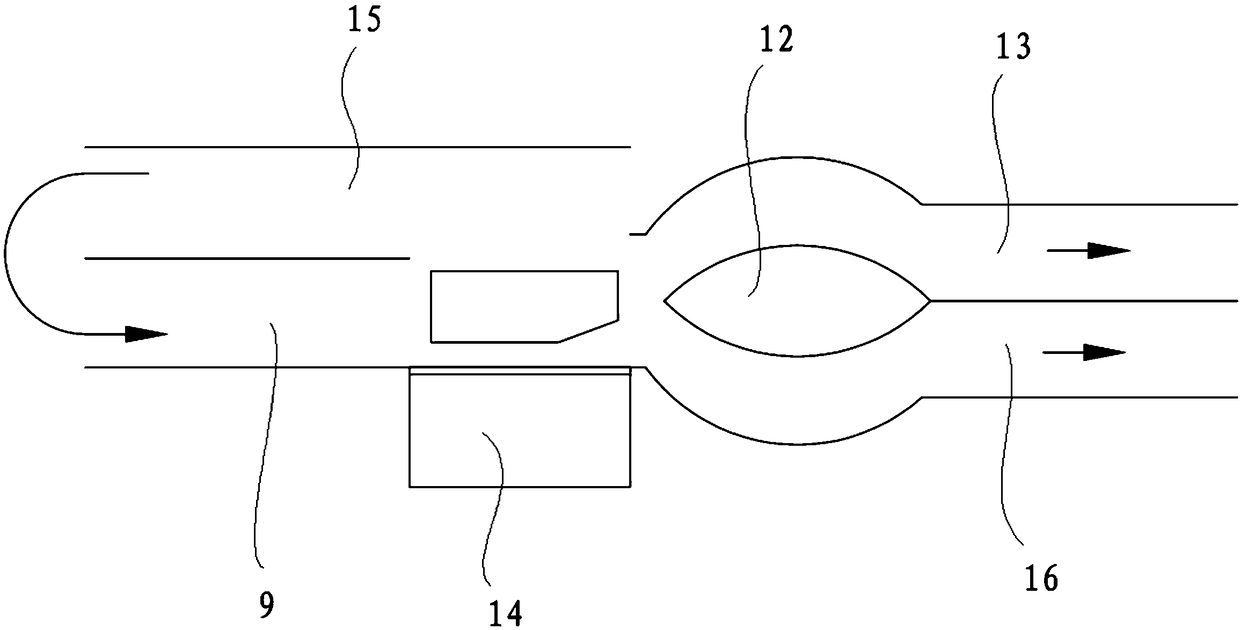

[0028] A wedge-shaped magnetic material pendulum distributing device according to an embodiment of the present invention, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes: vibrating feeding part 1, transmission column part 2, attitude adjustment part 3 and assembly part 4. The wedge-shaped magnetic material is transmitted to the transmission column part 2 through the vibration feeding part 1, and the attitude adjustment part 3 is used for Adjust the transmission posture of the wedge-shaped magnetic material passing through the transmission column part 2 according to the position of its gap; the vibration feed part 1, the transmission column part 2 and the posture adjustment part 3 form a spiral column, and the vibration feed part 1 is located on the bottom layer. The transmission column part 2 is located in the middle layer, and the attitude adjustment part 3 is located in the top layer. The wedge-shaped magnetic material is thrown into the vibrati...

Embodiment 2

[0035] Compared with Embodiment 1, Embodiment 2 adds the design of the depressing cover 17 on the vibrating feed part 1 on the basis of Embodiment 1, and the height between the depressing cover 17 and the vibrating feeding part 1 gradually increases along the conveying direction. Reduce until the height between the depressing cover 17 and the vibrating feeding part 1 is slightly higher than the thickness of the wedge-shaped magnetic material, that is, by setting the depressing cover 17 above the vibrating feeding part 1, the vibrating feeding part 1 is vibrated by an eccentric motor At the same time, by lowering the limit of the cover 17, it is further ensured that the posture of the wedge-shaped magnetic material when it enters the transmission partition part 2 is a flat state, the effect is better, and the wedge-shaped magnetic material on the vibrating feeding part 1 will not be affected by the vibration. And fly out or break away.

Embodiment 3

[0037] Compared with Embodiment 1, Embodiment 3 is also provided with a weighing reminding part 19 between the posture adjustment part 3 and the fitting part 4 on the basis of Embodiment 1, and the weighing reminding device 19 includes a load cell and a reminding device , when the load cell detects that the mass of the wedge-shaped magnetic material does not match the preset value range, the reminder device will send out a reminder. Specifically, when the wedge-shaped magnetic material passes through the load cell, it will measure a weight value, and the load cell will Numerical value is transmitted to corresponding data processing device, and data processing device carries out data comparison, if the weight value measured is not in the qualified weight value range, then data processing device sends corresponding signal to weighing reminding part 19, sends reminder; Reminding device adopts At this time, the relevant workers will take out the unqualified wedge-shaped magnetic ma...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap