Electric hydraulic grab bucket for dredge boat

A technology for hydraulic grabs and dredgers, which is applied in the direction of earth movers/excavators, load hanging components, construction, etc. It can solve the problems of low efficiency and small capacity of grab buckets, and achieves convenient assembly and avoids hydraulic pressure. Pipeline and grasping controllability are good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

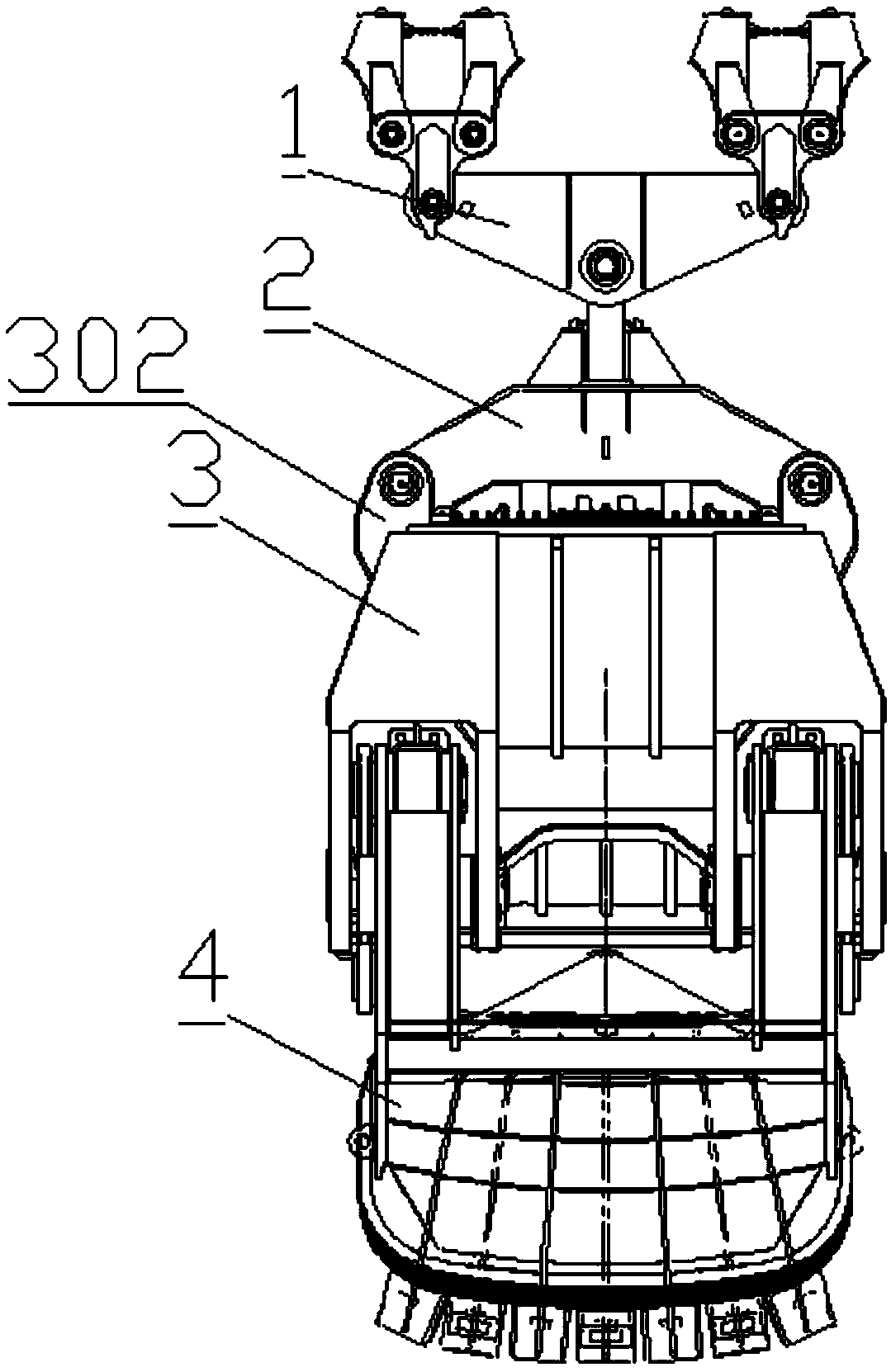

[0039] The core idea of the present invention is to provide an electro-hydraulic grab for a dredger, the hydraulic power system of the electro-hydraulic grab for a dredger is installed inside the bolster, avoiding long-distance hydraulic pipelines, lifting Capable of deep-sea operation; the two-lobed buckets are symmetrically distributed and can be opened and closed synchronously, with good grasping controllability; it has the characteristics of large bucket capacity, simple structure, convenient assembly, and simple manufacturing process.

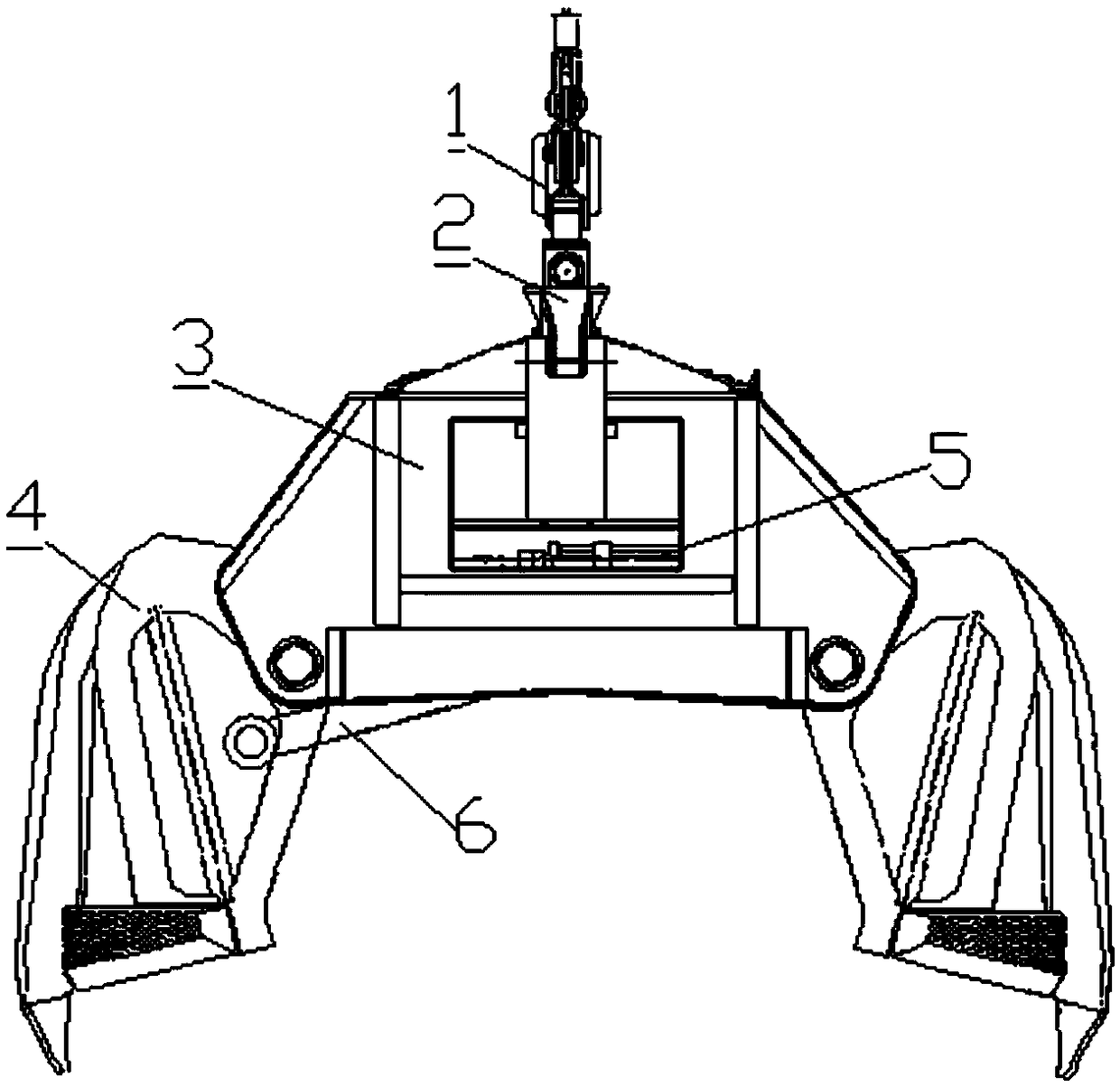

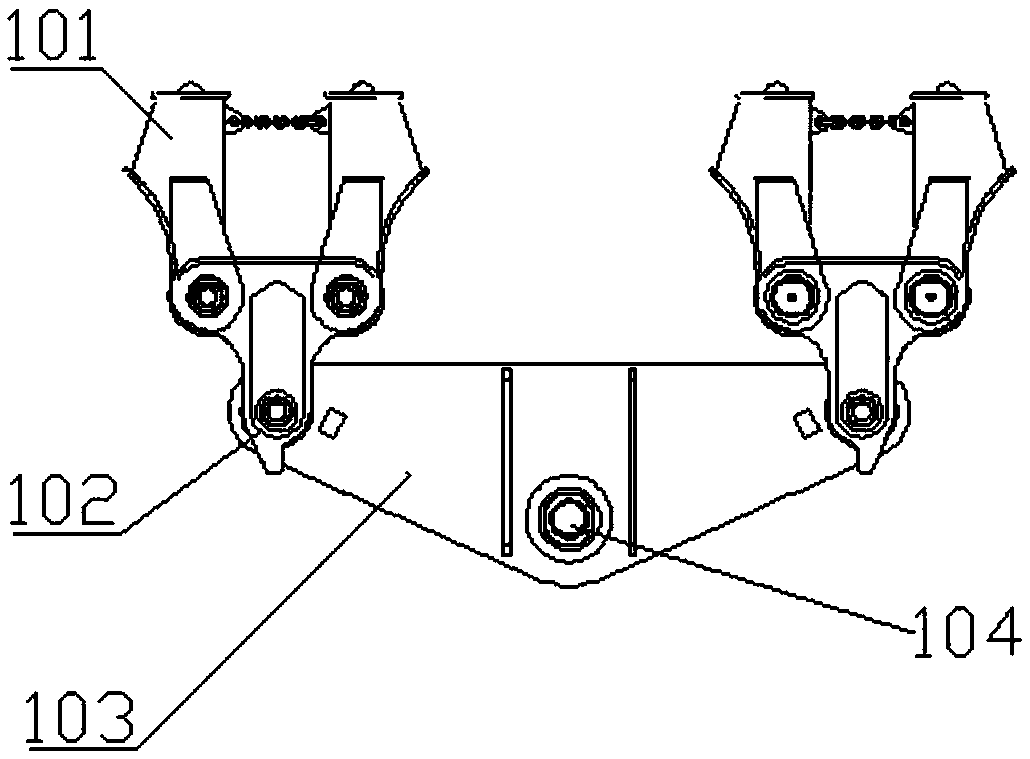

[0040]In order to realize the above ideas, the present invention provides an electro-hydraulic grab bucket for dredgers, including a load-bearing structure, a double-lobed bucket body, a synchronous structure, a connecting structure and a hydraulic power system, one end of the load-bearing structure is connected to the One end of the structure is connected, and the other end of the connection structure is used to connect with a lifting de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com