Special-shaped yarn spinning device and method

A special shape and equipment technology, applied in spinning machines, drafting equipment, yarns, etc., can solve problems such as poor yarn quality, poor fiber control, and failure to produce normally, and achieve good yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

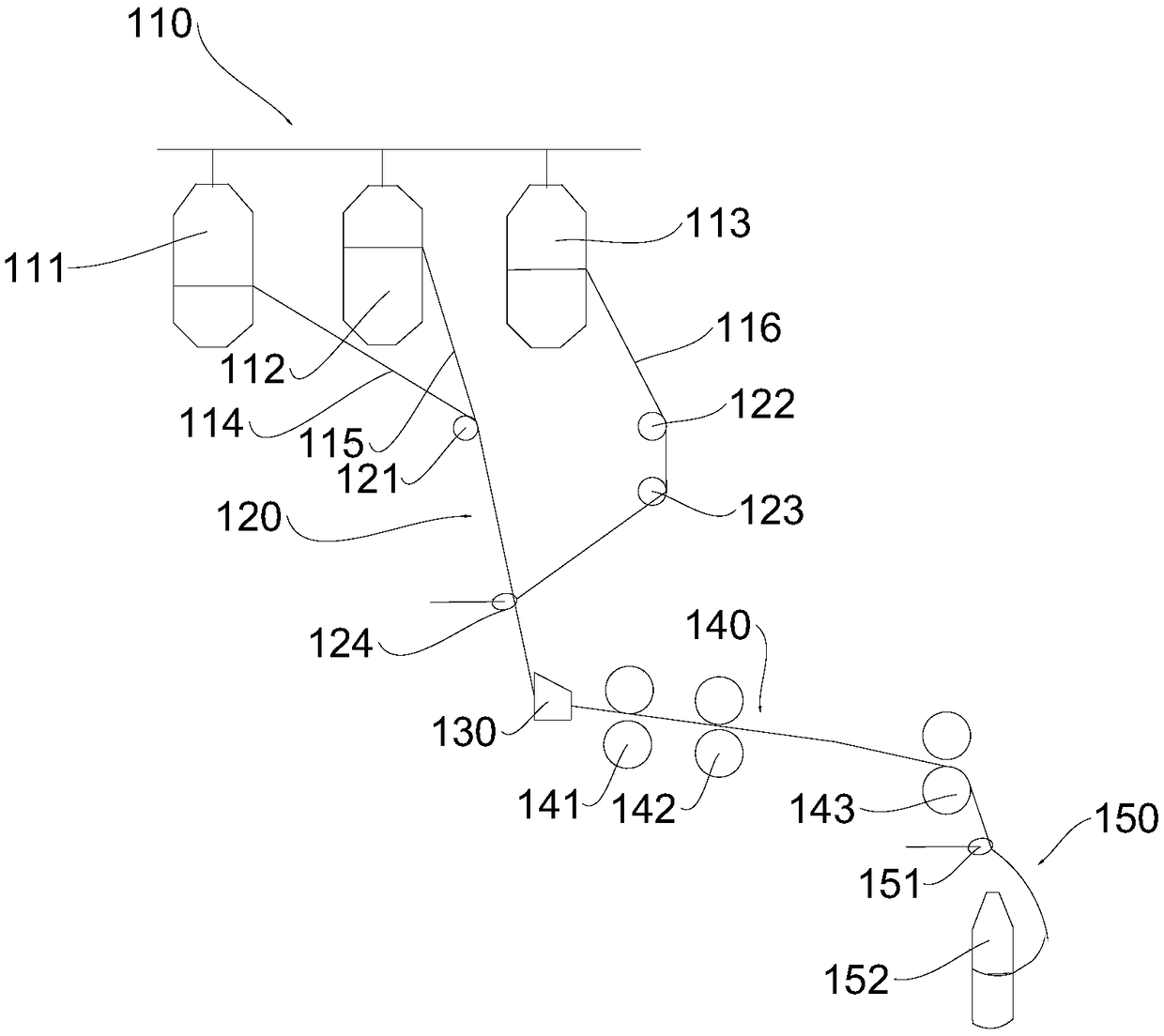

[0027] see figure 1 , The special-shaped spinning equipment includes a frame body, three roving frames 110 arranged in sequence, a yarn guide part 120, a guide part 130, a roller assembly 140 and a yarn forming part 150.

[0028] The frame body is the basis for installing other components of the special-shaped spinning equipment, and the three roving frames 110, the yarn guide part 120, the guide part 130, the roller assembly 140 and the yarn forming part 150 are all installed on the frame body. In this embodiment, the frame body includes a roving spindle, and three roving creels 110 are all arranged on the roving spindle, and each roving creel 110 is used to set a roving. Optionally, the three roving creels 110 are arranged side by side, so that the three rovings respectively arranged on the three roving creels 110 are arranged side by side for unwinding, so as to avoid the mixing of the three rovings.

[0029] The three creels 110 comprise a first creel 111, a second creel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com