Production method of wrinkled knitted weft-knitted fabric

A wrinkle knitting and production method technology, applied in the field of textile fabrics, can solve the problems of difficult quality control and cumbersome process, and achieve the effects of low cost, simple production process, and stable wrinkle style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: a kind of production method of crepe knitted weft-knitted fabric, comprises the following steps:

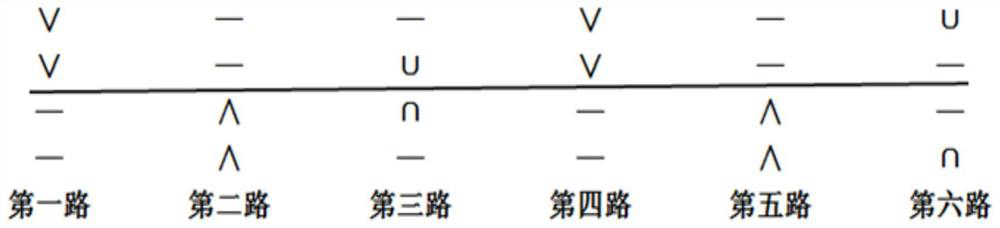

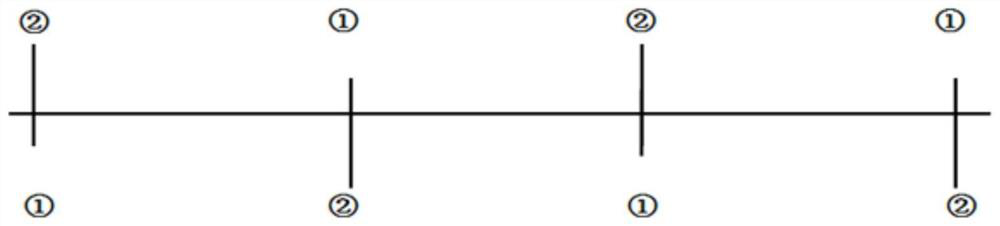

[0020] Provide a double-sided machine, arrange the triangles and knitting needles according to the requirements; in the present embodiment, adopt the double-sided machine of the Runshan RS model, the machine number 28G needle cylinder, and the cylinder diameter is 34 ". The triangle arrangement method is as follows figure 1 As shown, knitting needles such as figure 2 to arrange. in, figure 1 Among them, "∪∩" means tangle triangle; "∨∧" means circle triangle; "─" means floating line triangle. figure 2 "∣"① means the first knitting needle; ② indicates the second knitting needle.

[0021] Yarns are provided, including polyester PTT, polyester stretch textured yarn, and polyester composite stretch textured yarn. The polyester PTT is 100D / 36F polyester PTT, and the crimp shrinkage is 36%-38%. The polyester stretch-textured yarn is 100D / 144F polyester stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com