Layered composite type elastic cushion block and preparation method thereof

A layered composite and elastic pad technology, which is applied in the field of rail transit, can solve the problem that the elastic pad cannot meet the operating conditions, and achieve the effect of preventing the rate of change from being too large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

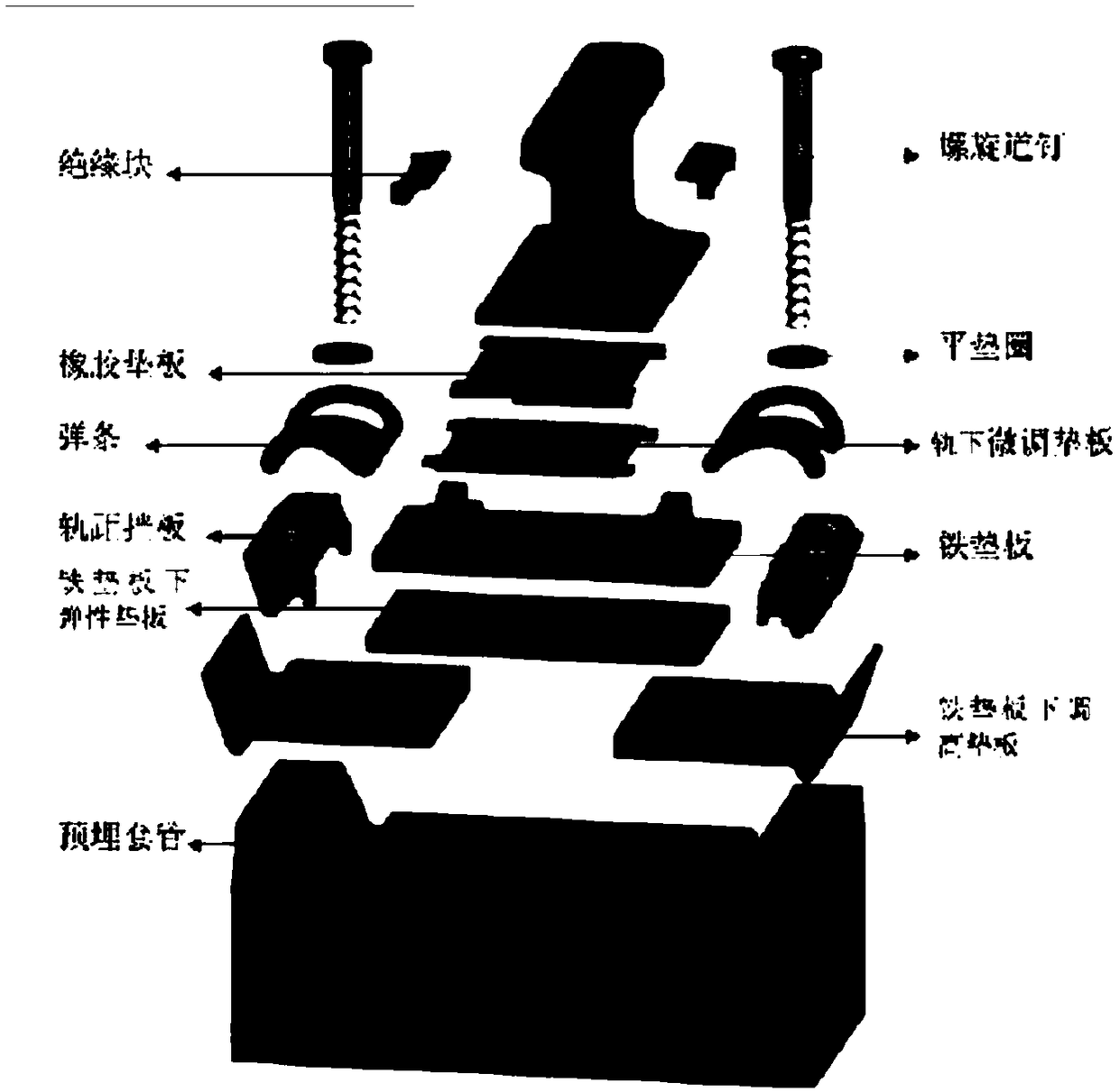

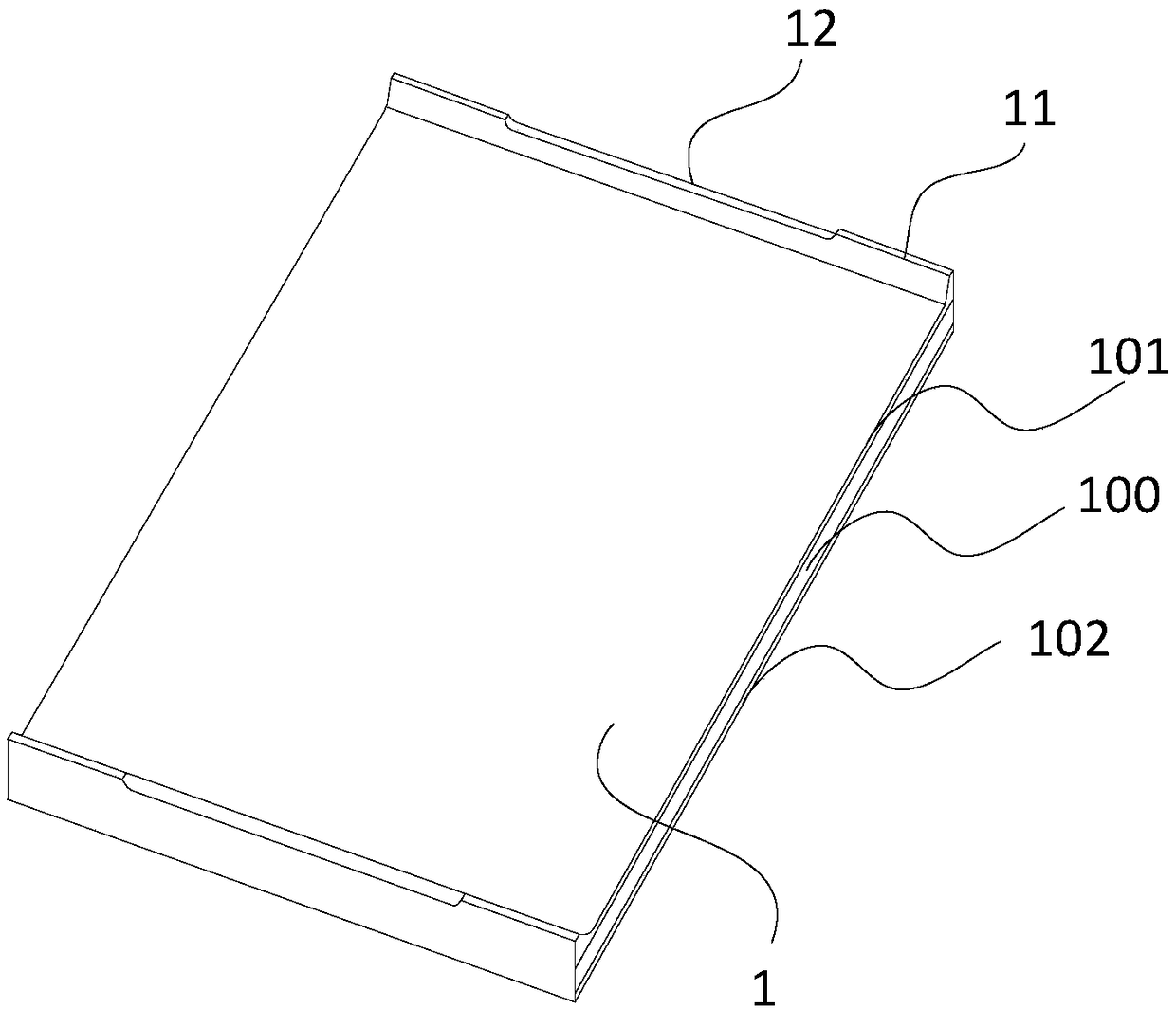

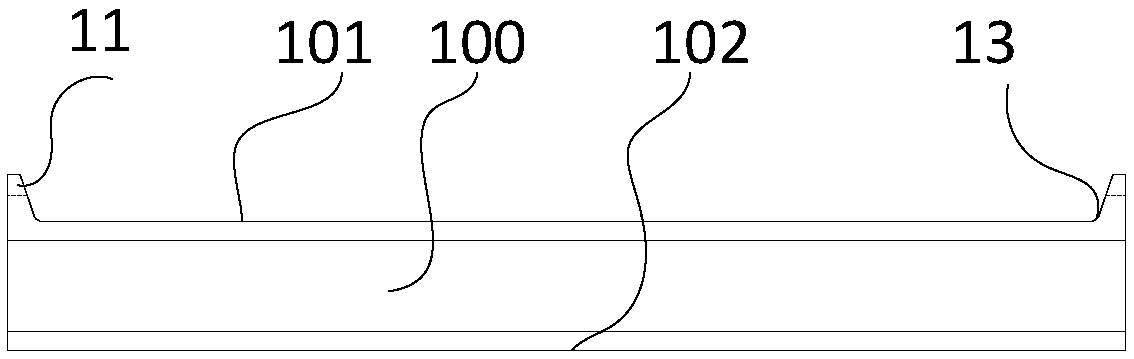

[0040] Such as Figure 2 to Figure 4 As shown, this embodiment provides a layered composite elastic pad, which aims to ensure the rigidity support, reduce the rate of static stiffness change, and at the same time ensure the shock absorption and buffering effects of the pad. Specifically, the composite elastic pad 1 includes an intermediate cushion layer 100 with a cuboid structure installed between the rigid rail and the concrete pillow, attached to the intermediate cushion layer 100, and used for the intermediate cushion layer 100 The lower thermal insulation layer 102 and the upper thermal insulation layer 101 for thermal insulation are arranged on the edges of both sides of the upper thermal insulation layer 101 and the side convex strips 11 integrally formed with the upper thermal insulation layer 101 are provided in any The concave strip 12 on the side convex strip 11 and the joint surface 13 provided between the side convex strip 11 and the upper thermal insulation layer...

Embodiment 2

[0042] Such as Figure 5 As shown, this embodiment provides a method for preparing a layered composite elastic cushion block, wherein the intermediate cushion layer is made of polyurethane, thermosetting elastomer material or rubber material. The material of the lower thermal insulation layer is the same as that of the upper thermal insulation layer, and is one of foamed silica gel and foamed rubber added with XPS polystyrene foam. The upper thermal insulation layer, the middle cushion layer and the lower thermal insulation layer are bonded sequentially from top to bottom.

[0043] Described preparation method comprises the following steps:

[0044] In the first step, put the white gray black in a vacuum oven and dry it under vacuum at 120°C for 3 hours to remove the moisture in the white gray black to obtain dry white gray black.

[0045] The second step, pretreatment of aluminum silicate fiber: first soak the fiber with 0.01mol / L hydrochloric acid solution and clean it wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com