Prefabricated assembly type concrete structure leisure plank road and construction method thereof

A concrete structure, prefabricated assembly technology, applied in the direction of roads, roads, pavements, etc., can solve the problems of high cost, poor durability, and large maintenance workload, and achieve the effect of overcoming poor durability and overcoming large amount of soil filling works.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

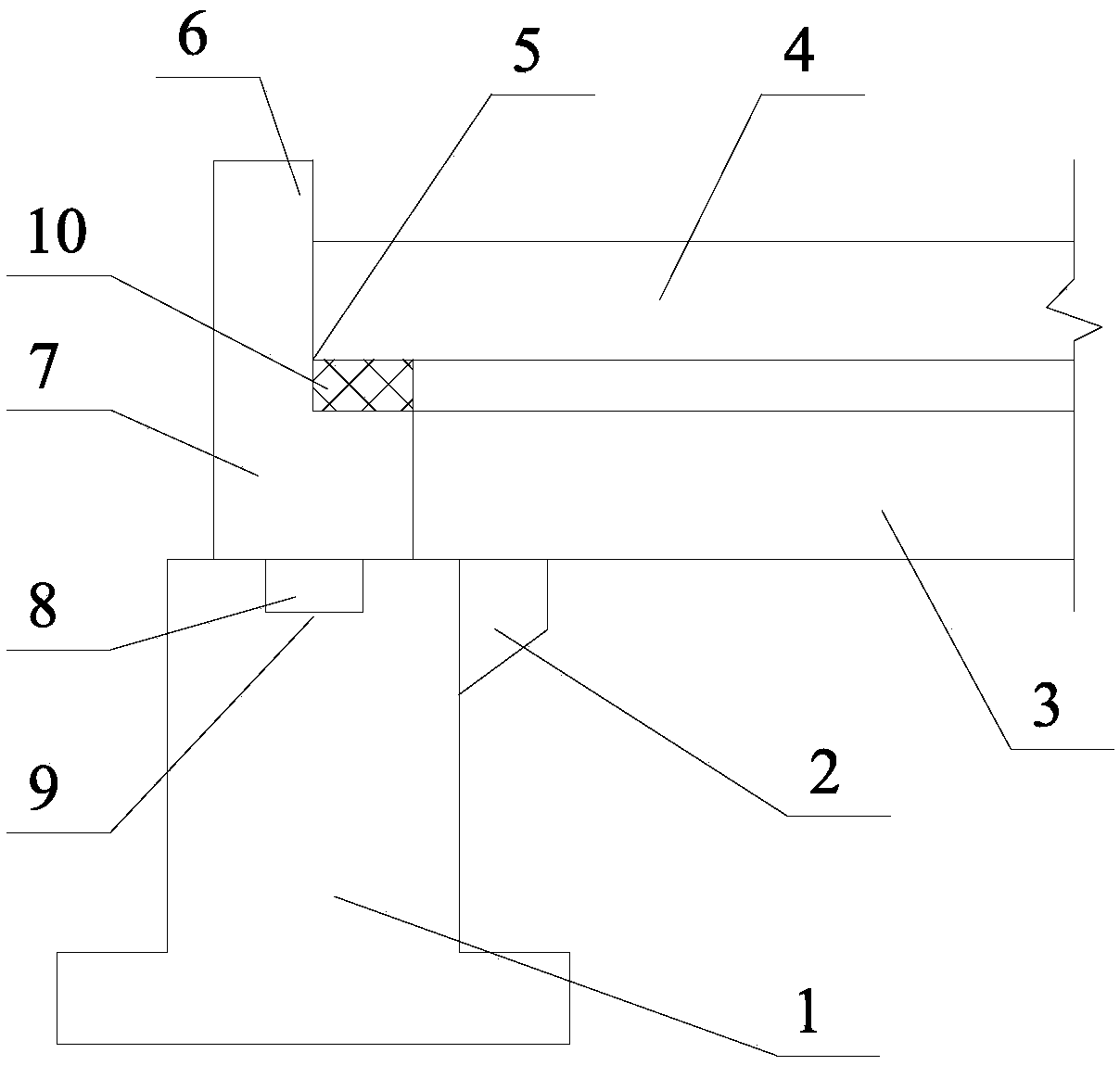

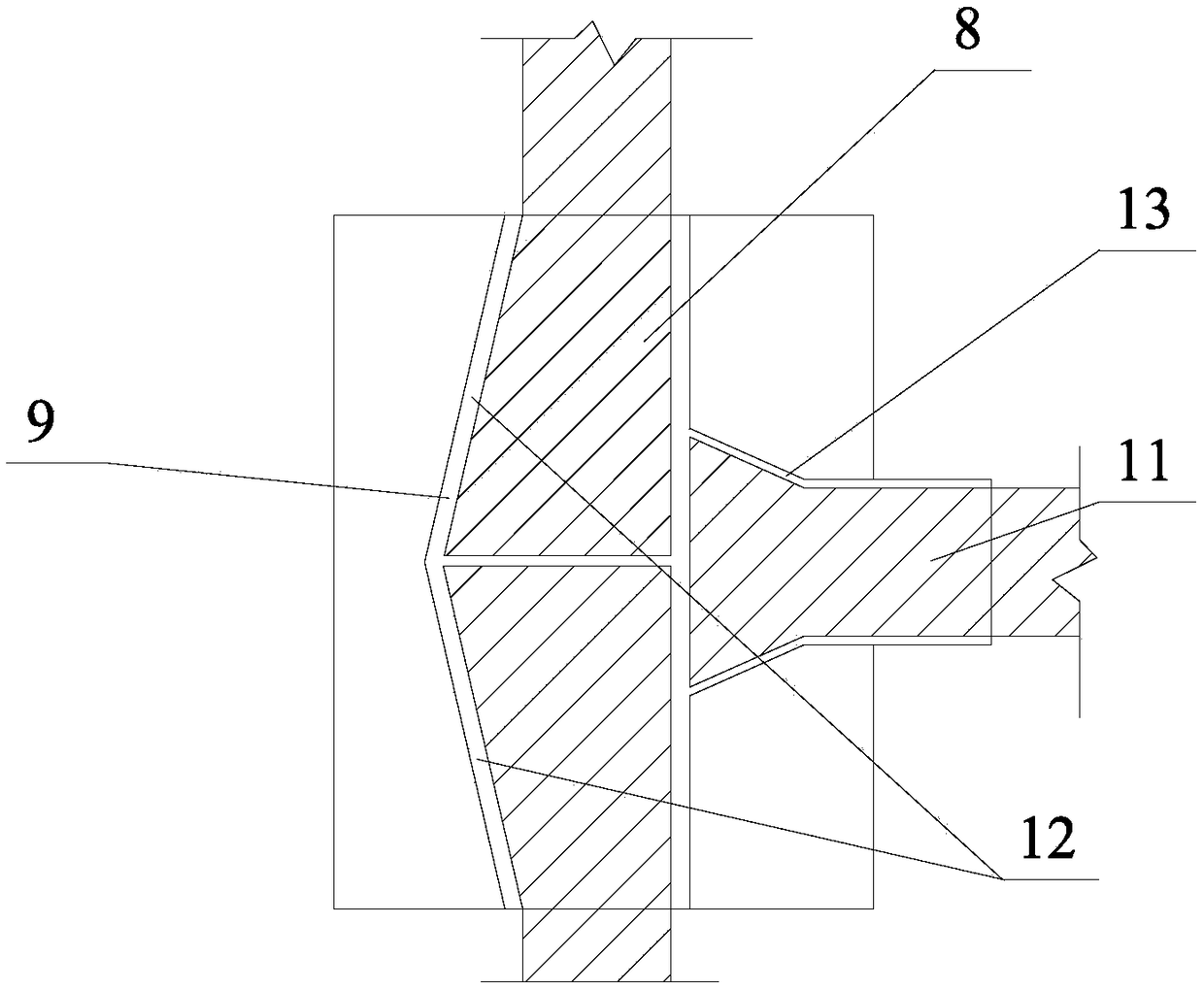

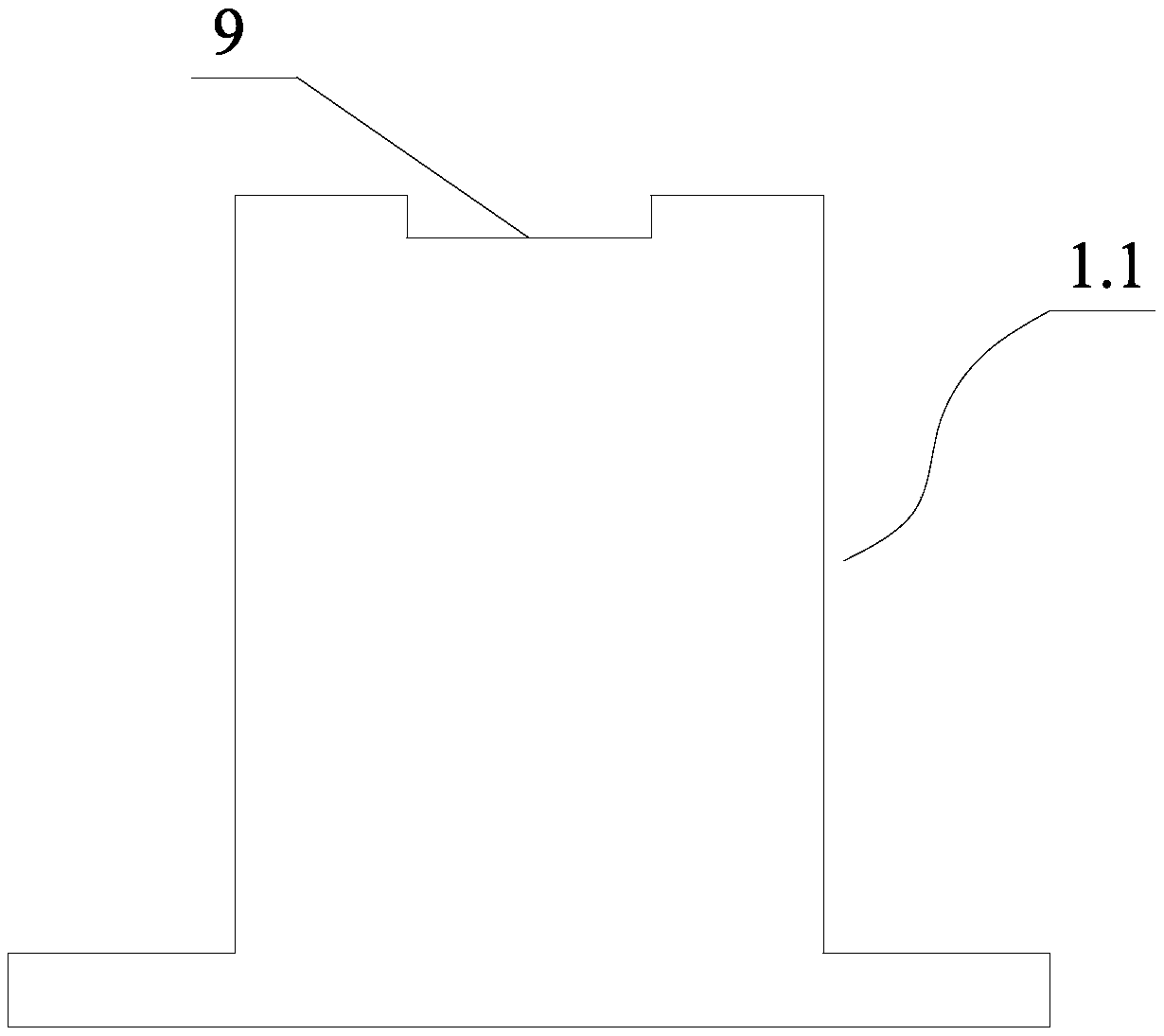

[0037] It also includes a number of reinforced concrete prefabricated side beams 7 extending along the length direction of the plank road, each side beam 7 has an inward L-shaped groove 5, and the height of the vertical side of the L-shaped groove 5 of the side beam 7 is higher than that of the plank road. The height of board 4 is to form the skirting edge 6 of plank road, and skirting edge 6 also has claim base line. The end of each side beam 7 and each column 1 have a structure that restricts the vertical movement of the side beam 7 such as the X direction and the horizontal movement such as the Y direction, as in the first specific embodiment: the top surface of each column 1 has a The first groove 9 that runs through the length direction, the outer side of the first groove 9, that is, the side away from the following connecting beam 3, is two hypotenuses 12 that are inclined from the middle to the openings at both ends, and the first groove 9 The middle is wide and the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com