Positioning, installing and dismounting tool and method of long-span continuous rigid frame suspension pouring end template

A technology of positioning and installation, end formwork, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of low investment, high construction risk, low formwork construction efficiency, etc., and achieves more repeated use and reduced formwork removal time. , the effect of reinforcement and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

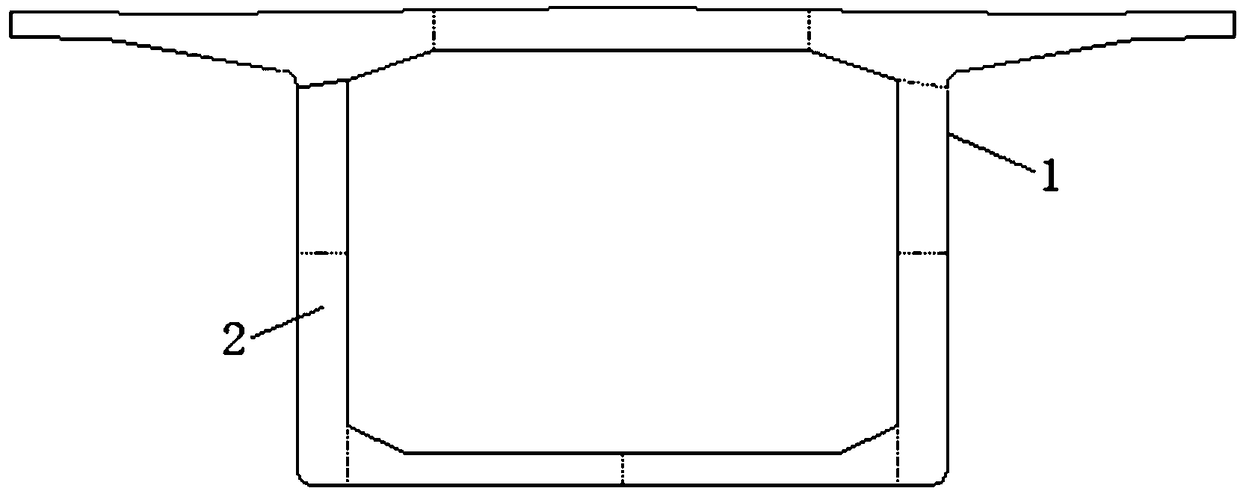

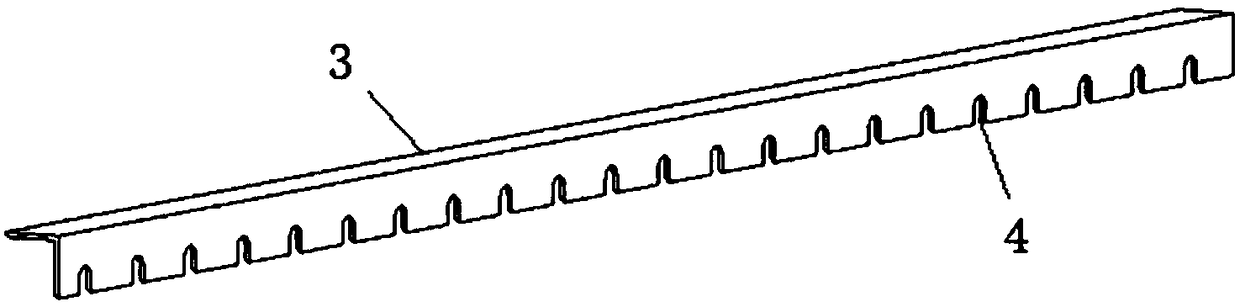

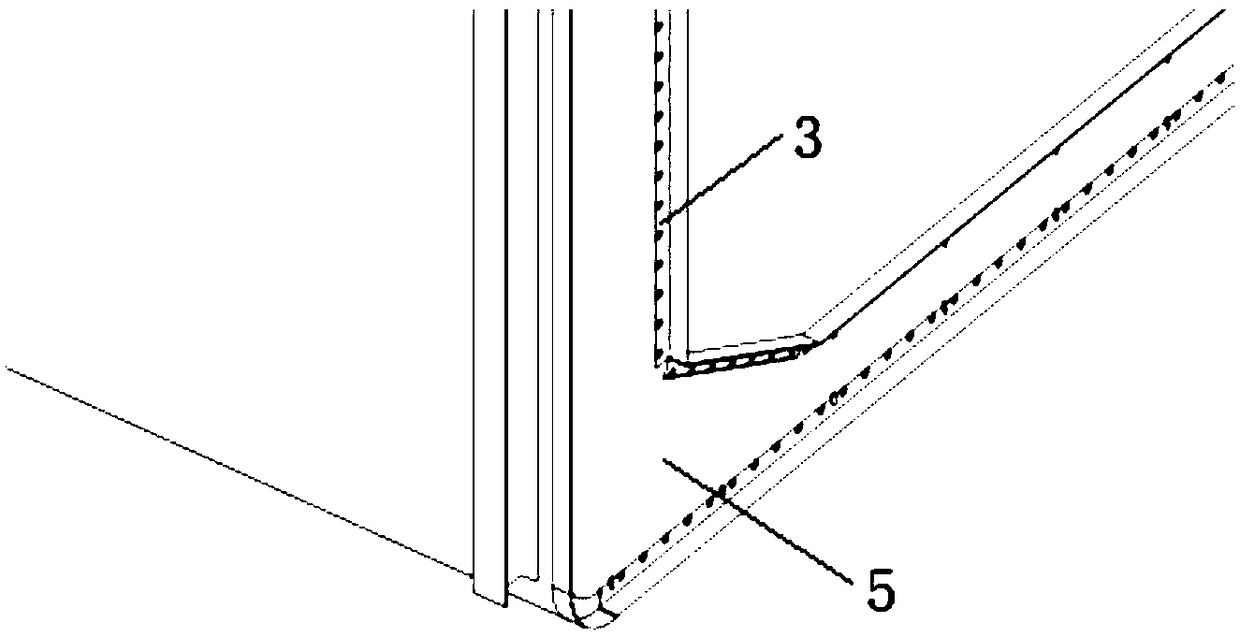

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. A large-span continuous rigid-frame suspended irrigation end formwork positioning installation and removal tooling includes an integral beam end formwork 1 composed of a plurality of formwork units 2, and the formwork units 2 are divided according to the positions of holes reserved for steel bars. The template unit 2 includes a fixed-length steel plate 5 and a fixed-length angle steel 3; the steel bar hole groove 4 is set on the fixed-length angle steel 3; Wherein, the fixed-length steel plate 5 and the fixed-length angle steel 3 are fixedly connected by short steel bars 7 .

[0021] Working principle: This device makes full use of the principle of integral end template composed of template units. The fixed-length 5cm×5cm angle steel is grooved according to the designed spacing of the steel bars, which is not only a fixture for positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com