A building assembly connection component

A technology of connecting components and sliding connection, which is applied in the direction of construction, building structure, and building material processing, etc., can solve the problems of unsafe operation process, poor docking quality, and labor-intensive, etc., to achieve convenient operation, improve safety performance, Avoid the effects of manual support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

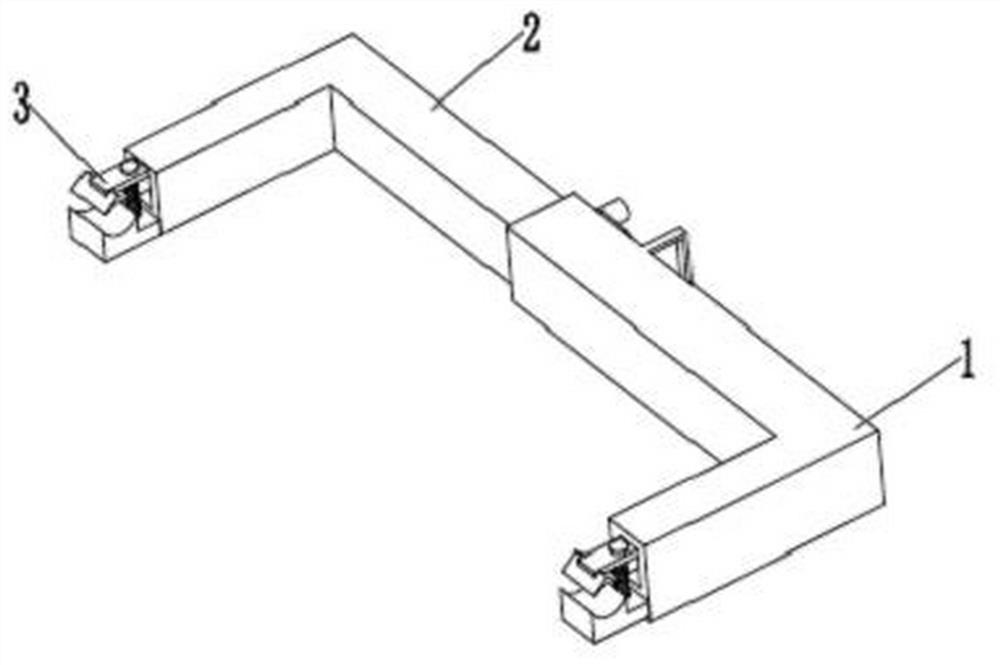

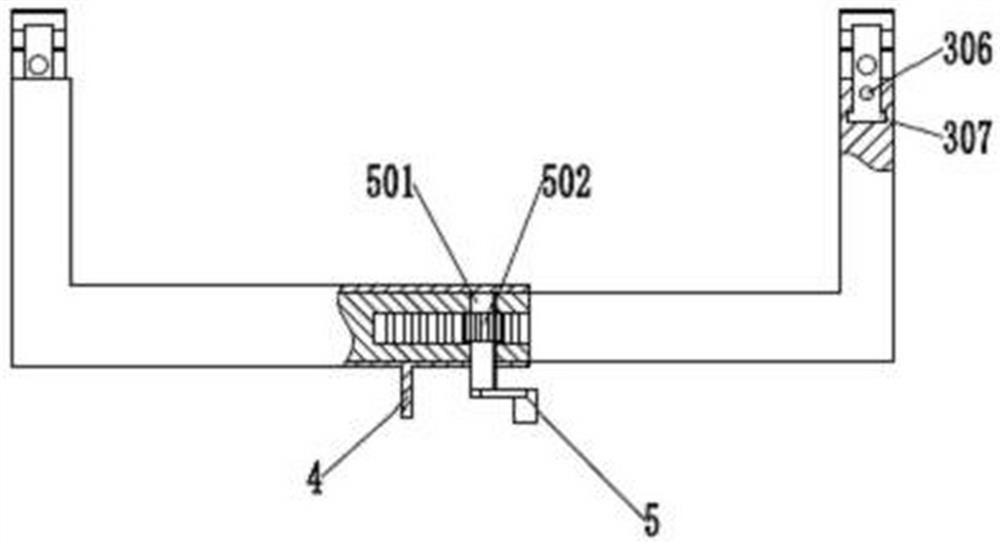

[0026] see Figure 1-4 , a building assembly connection assembly, including a fixed part 1, a movable part 2, a fixed chuck 3 for clamping steel bars, and a distance adjustment device, the fixed part 1 and the movable part 2 are both "L" shaped structures, and the fixed The sliding connection between the part 1 and the movable part 2, the ends of the fixed part 1 and the movable part 2 are provided with mounting holes 6, the fixed chuck 3 is matched with the mounting hole 6, and the jaw size of the fixed chuck 3 It can be adjusted, and the distance adjusting device is arranged on one side of the fixed part 1, and the distance adjusting device cooperates with the movable part 2, and a handle 4 is provided on one side of the distance adjusting device.

Embodiment 2

[0028] In this embodiment, a construction assembly connection assembly includes a fixed part 1, a movable part 2, a fixed chuck 3 for clamping a steel bar, and a distance adjustment device. Both the fixed part 1 and the movable part 2 are "L" "type structure, sliding connection between the fixed part 1 and the movable part 2, the ends of the fixed part 1 and the movable part 2 are provided with mounting holes 6, the fixed chuck 3 is matched with the mounting hole 6, and the fixed chuck The jaw size of 3 can be adjusted, and the distance adjusting device is arranged on one side of the fixed part 1, and the distance adjusting device cooperates with the movable part 2, and a handle 4 is provided on one side of the distance adjusting device.

[0029] In this embodiment, the end of the fixed part 1 is provided with a fitting hole 101 , and the end of the movable part 2 is arranged in the fitting hole 101 , and the two are slidably connected.

[0030] In this embodiment, one side of...

Embodiment 3

[0033] In this embodiment, a construction assembly connection assembly includes a fixed part 1, a movable part 2, a fixed chuck 3 for clamping a steel bar, and a distance adjustment device. Both the fixed part 1 and the movable part 2 are "L" "type structure, sliding connection between the fixed part 1 and the movable part 2, the ends of the fixed part 1 and the movable part 2 are provided with mounting holes 6, the fixed chuck 3 is matched with the mounting hole 6, and the fixed chuck The jaw size of 3 can be adjusted, and the distance adjusting device is arranged on one side of the fixed part 1, and the distance adjusting device cooperates with the movable part 2, and a handle 4 is provided on one side of the distance adjusting device.

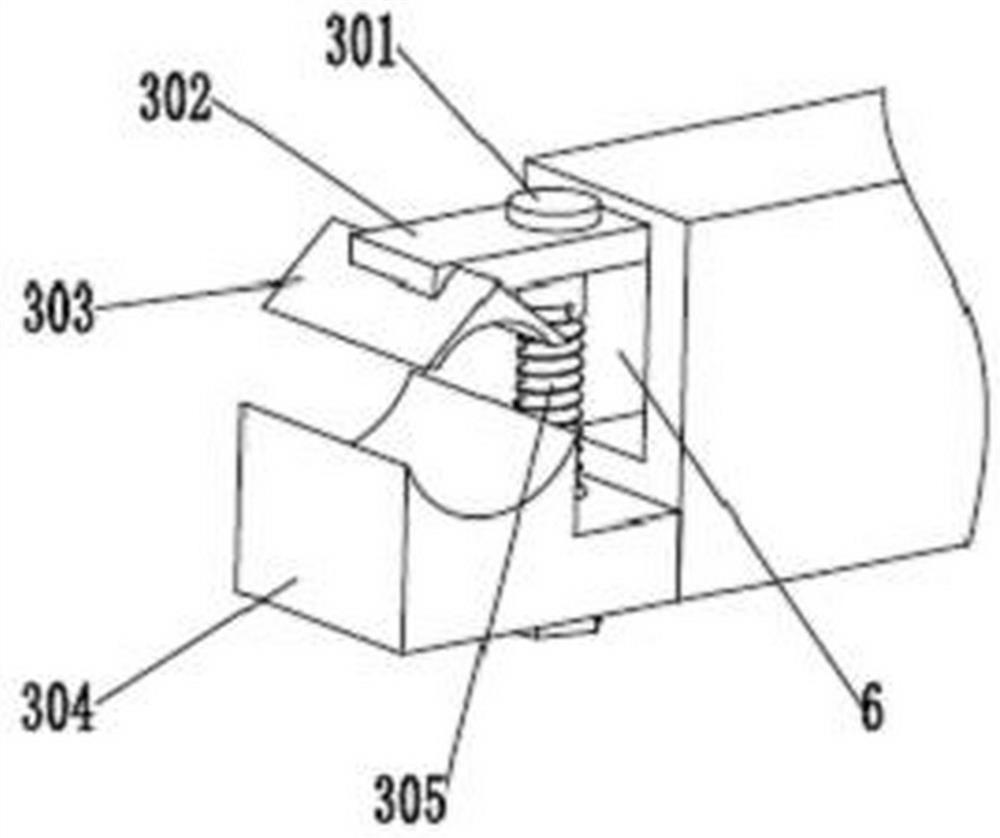

[0034] In this embodiment, the fixed chuck 3 includes an adjusting rod 302, a movable clamp 303, a fixed clamp 304, and a threaded rod 305. One end of the fixed clamp 304 is arranged on the lower side of the mounting hole 6, and the fixed cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com