Composite self-resetting hydraulic damper

A hydraulic damper, self-resetting technology, applied in the direction of building types, building components, earthquake resistance, etc., can solve the problems of building damage, high energy consumption, etc., achieve high energy consumption, simple structural design, and solve the effect of building damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

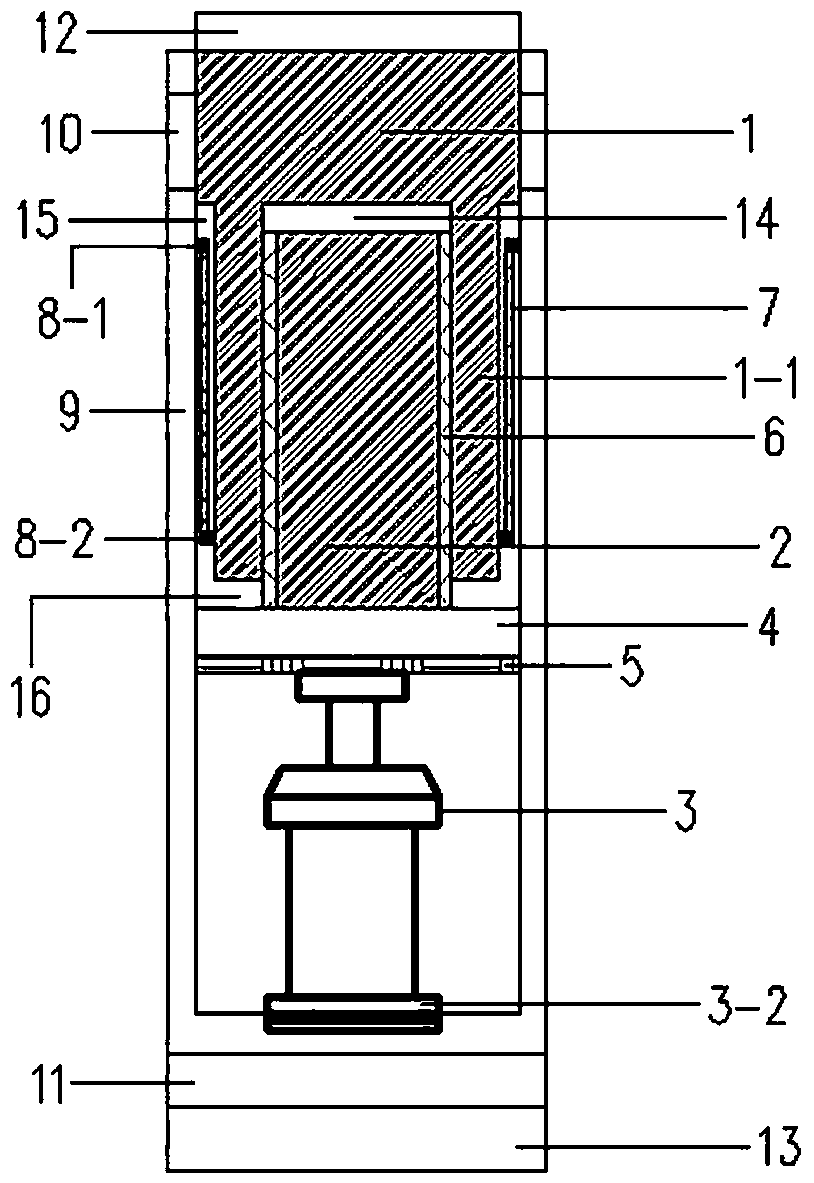

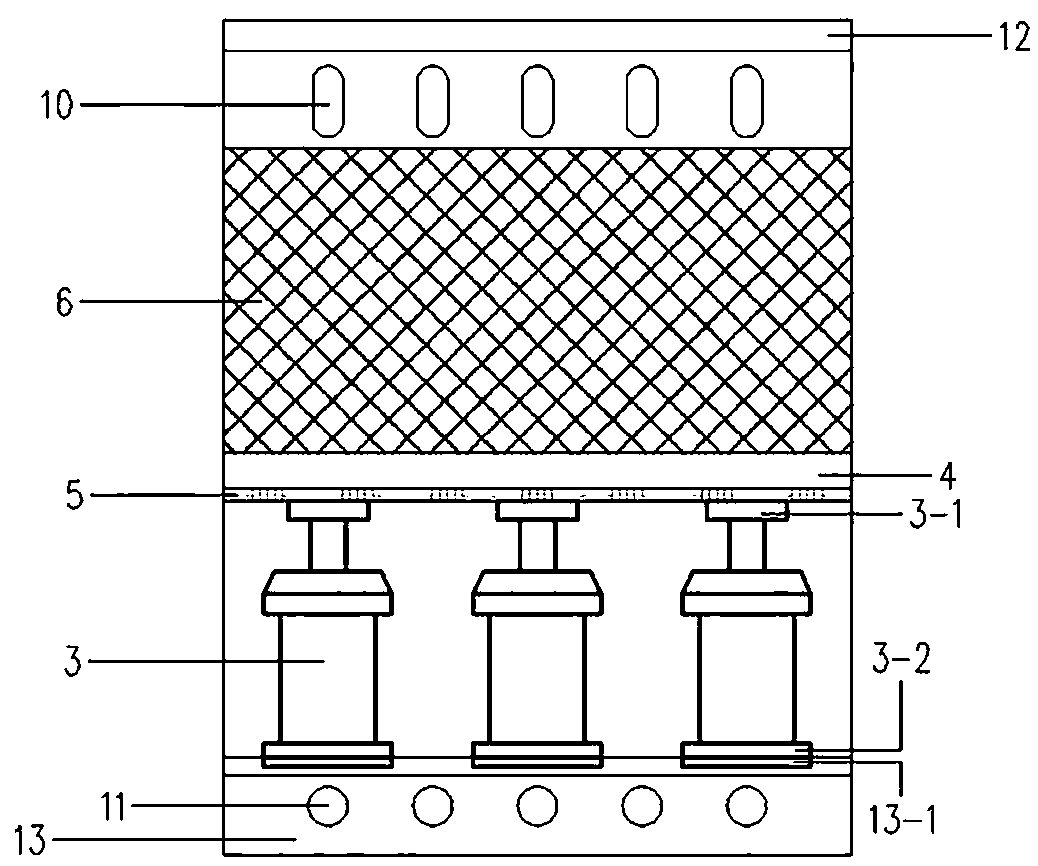

[0019] Example: such as Figure 1-2 As shown, a composite self-resetting hydraulic damper includes an upper friction plate 1, a lower friction plate 2, a hydraulic buffer 3, a limit plate 4, a CFRP plate 5, a friction material 6, an SMA wire 7, and an upper connecting guide rod 8-1, lower connecting guide rod 8-2, outer frame plate 9, sliding limit hole 10, connecting hole 11, upper end plate 12, lower end plate 13;

[0020] The upper friction plate 1 is in the shape of a letter, and the lower friction plate 2 is in the shape of a letter. The upper friction plate 1 and the lower friction plate 2 are made of 35CrMoA alloy structural steel. Friction material 6, the friction material 6 is Portland cement or powder metal friction material, the friction coefficient is not less than 0.35, the friction material 6 is coated or sintered and the length is consistent with the length of the lower friction plate 2; the top of the upper friction plate 1 has an upper end plate 12, The width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com