Assembly-type multifunctional prefabricated external window standard sleeve and installation method

A multifunctional and prefabricated technology, applied in window/door frame, condensed water discharge, frame fixation, etc., can solve the problems of increased construction cost, lowered construction quality, and slowed down construction progress, so as to reduce manpower, reduce weight, The effect of speeding up the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

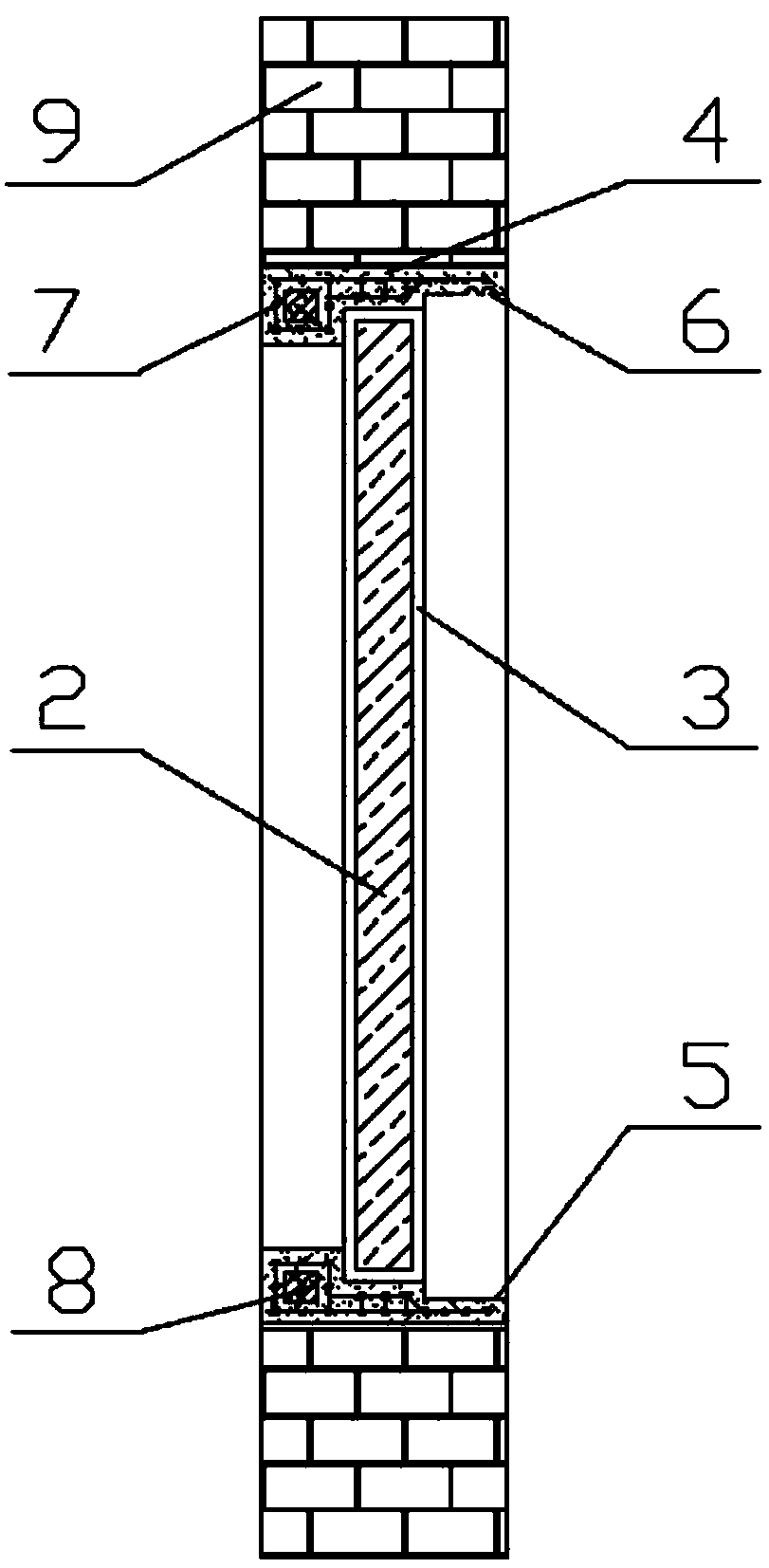

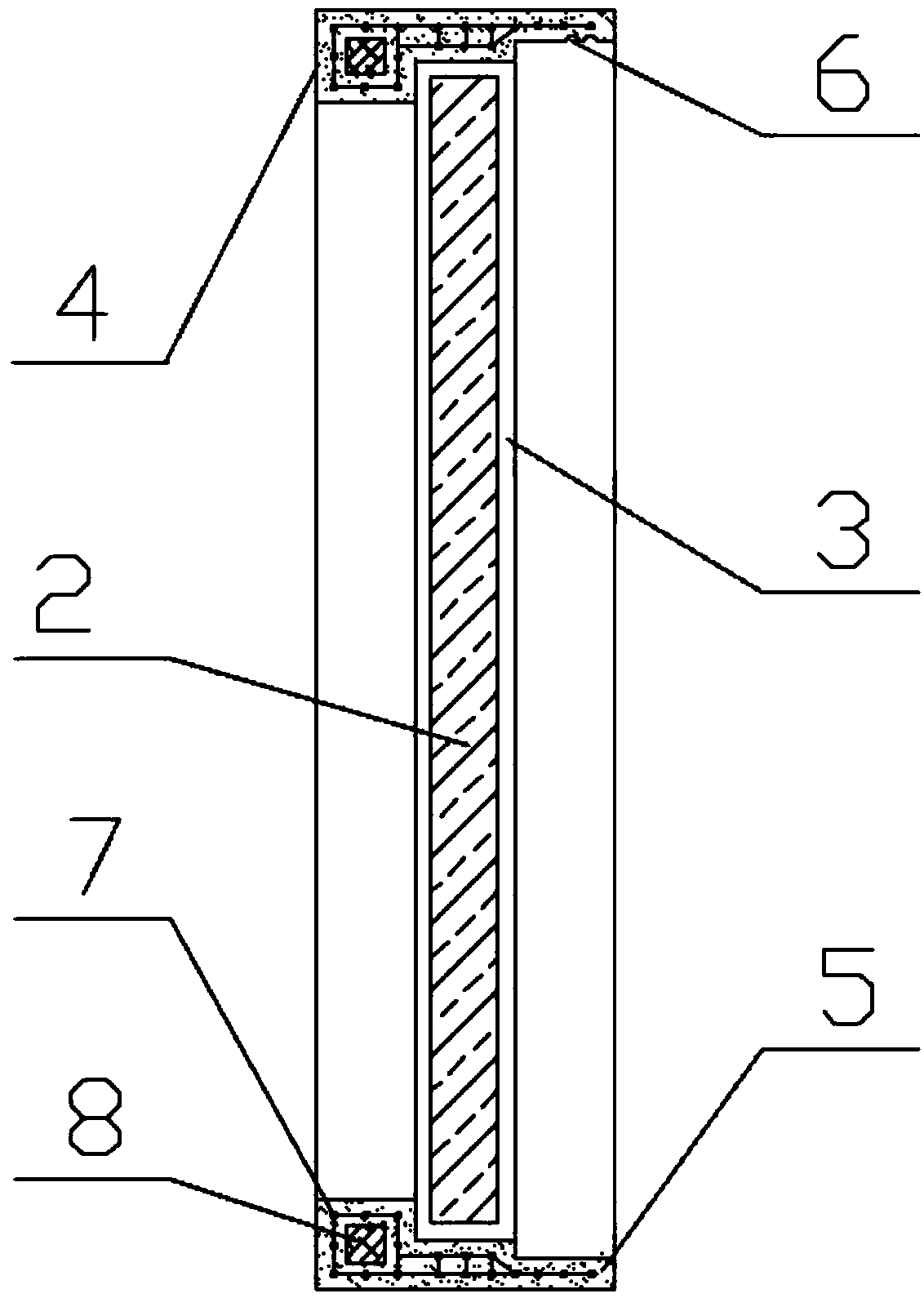

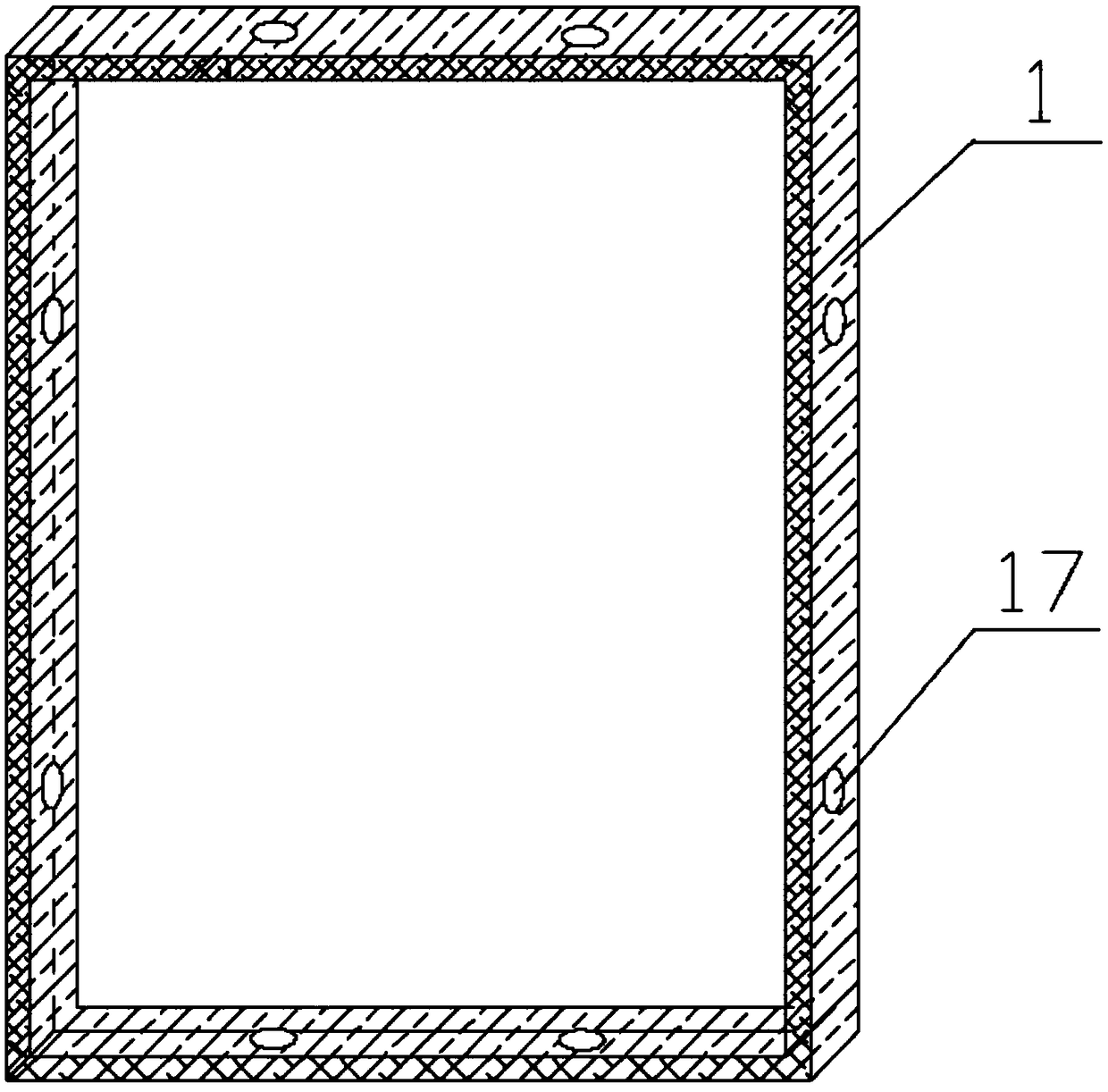

[0029] Such as Figure 1 to Figure 3 An assembled multifunctional prefabricated outer window standard cover shown in the figure includes a window cover 1, the window cover 1 is arranged in a wall 9, and the upper and lower ends of the window cover 1 are provided with a window sash upper edge 4 and a window sash The lower edge 5, the upper edge 4 of the window sash and the lower edge 5 of the window sash are successively provided with three steps of different heights from the inside to the outside, and the height of the steps decreases successively from the inside to the outside. A window frame 3 is provided on the step in the middle of the lower edge 5, and a window sash 2 is arranged inside the window frame 3, and a built-in heat preservation warehouse 8 is provided inside the steps inside the upper edge 4 of the window sash and the lower edge 5 of the window sash. , the built-in insulation bin 8 is a hollow structure.

[0030] Wherein, the four sides of the window cover 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com