Door and window sealing rubber strip changer

A technology of sealing strip and changer, which is applied in the directions of sealing device and wing fan arrangement, etc., can solve the problems of difficult removal, reducing the overall service life of sliding doors and windows, and inability to reinstall the sealing strip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

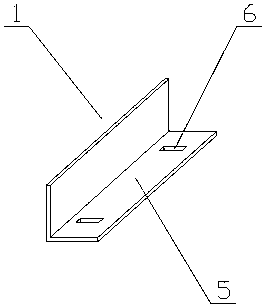

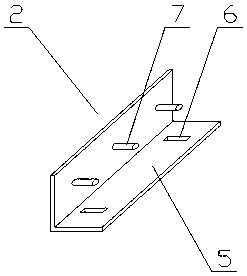

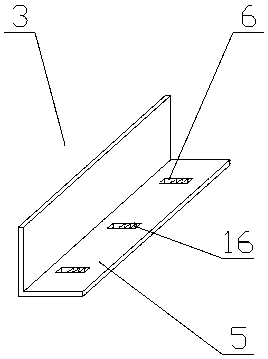

[0023] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. like Figure 1 to Figure 8 Shown: a door and window sealing strip replacement device, which is composed of a first bending plate 1, a second bending plate 2, a third bending plate 3 and a fourth bending plate 4,

[0024] The above-mentioned first bending plate 1 is composed of two sub-plates 5 perpendicular to each other, and two long holes 6 are symmetrically opened on one of the sub-plates 5 ,

[0025] And the second bent plate 2 is also composed of two sub-plates 5 perpendicular to each other, two long holes 6 are symmetrically opened on one of the sub-plates 5, and three connecting bolts 7 are arranged on the other sub-plate 5 , and the three connecting bolts 7 are evenly distributed,

[0026] The third bent plate 3 is also made up of two sub-plates 5 that are perpendicular to each other, and one of the sub-plates 5 is provided with thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com