Wire-passing structure for small flow rate center flow-concentrating flowmeter of oil field

A technology of small flow rate and flow meter, which is applied in the direction of measurement, drilling equipment, wellbore/well components, etc., can solve the problems caused by sealing plugs and rubber sleeves, require more key control points, and reduce reliability, etc., to achieve good protection Function, convenient and fast disassembly and assembly, and the effect of reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

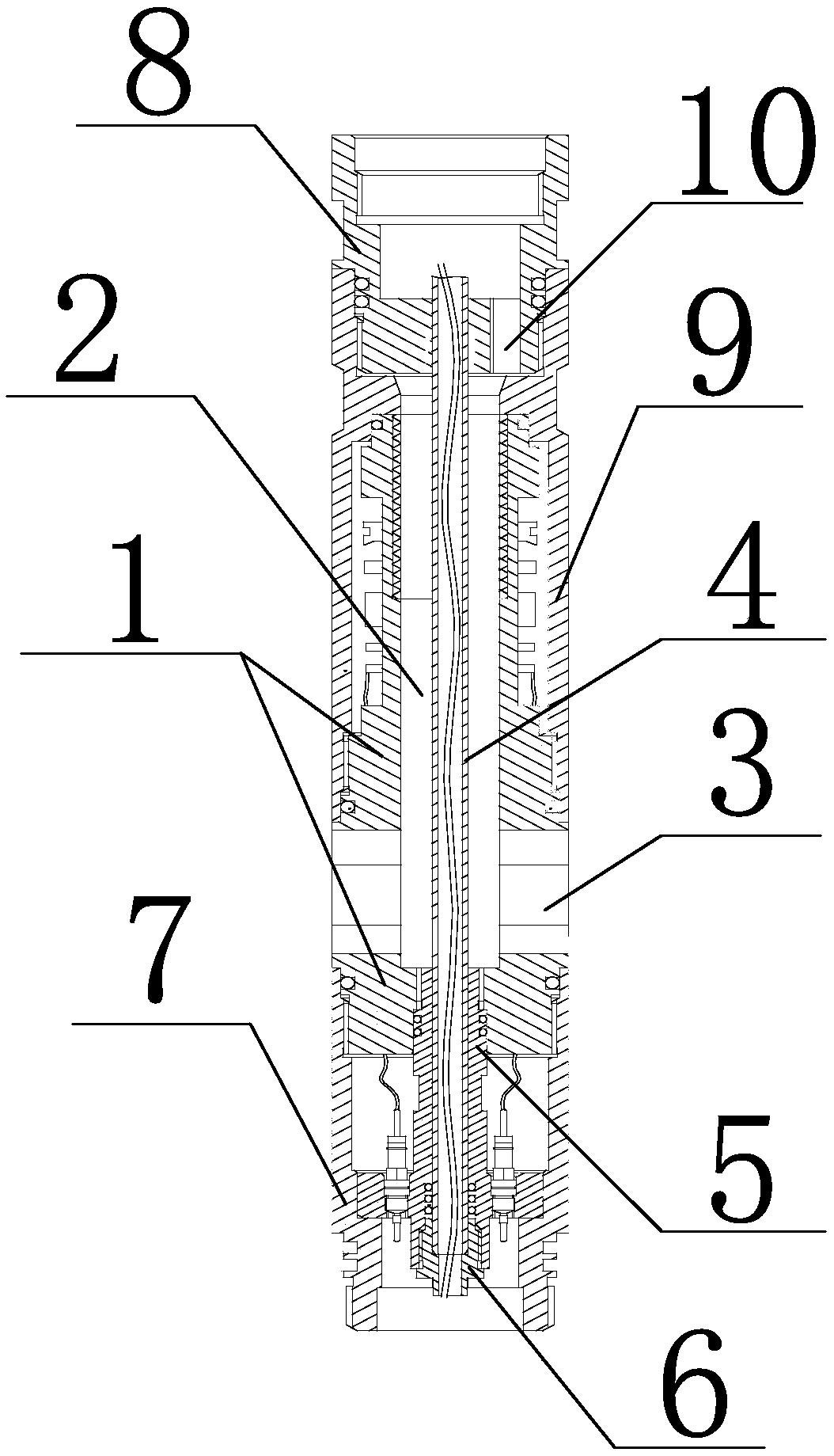

[0022] Such as figure 1 As shown, the present invention is a small-flow center-collecting flowmeter line-passing structure for oilfields, including a main body 1 for installing an electromagnetic flowmeter. The main body 1 is provided with a water-passing hole 2 that runs through the upper and lower end faces, and is close to the water-passing hole 2. The side wall of the main body 1 at the lower end of the hole 2 is provided with a water outlet 3 communicating with the water hole. The water hole 2 is provided with a wire passing steel pipe 4 for threading through the upper and lower ends of the water hole 2. The wire passing steel pipe 4 An annular liquid flow channel is formed between the outer wall of the water hole 2 and the inner wall of the water hole 2. The liquid flow channel communicates with the oil pipe through the top of the water hole 2 and the water outlet 3 to form a high-pressure zone. The outer walls of the upper and lower ends of the steel pipe 4 are sealed T...

Embodiment 2

[0025] The present invention is a line-passing structure for small-flow center-collecting flowmeters used in oil fields. On the basis of Embodiment 1, a steel pipe core 5 is sleeved between the inner wall of the lower end of the water passage hole and the outer wall of the steel pipe passing through the line. The inner wall and the outer wall of the core body are equipped with sealed O-shaped packing, and the inner wall of the steel pipe core body and the outer wall of the passing steel pipe are sealed by the sealed O-shaped packing, and the outer wall of the steel pipe core body and the lower end of the water hole on the main body The inner wall is sealed by sealing O-shaped packing; the lower end of the steel pipe core extends out of the water hole of the main body, and the inner wall of the lower end of the steel pipe core is provided with threads, and the inner wall of the lower end of the steel pipe core is threaded with a steel pipe positioning pressure core 6. The thread...

Embodiment 3

[0028] The present invention is a line-passing structure for a small-flow center-collecting flowmeter in an oil field. On the basis of Embodiment 1, the upper end of the main body is connected with a terminal 8, and a threading hole is provided in the terminal. The outer walls of the line steel pipes are sealed and connected by a sealed O-shaped packing, and a plurality of water inlet holes 10 are arranged around the wire hole, and the water inlet holes communicate with the annular liquid flow channel.

[0029] The upper end of the steel pipe passing through the line is sealed and connected to the inner wall of the upper end of the water hole through the end and the sealed O-shaped packing. There are multiple water inlet holes around the threading hole, that is, the liquid flow at the upper end enters through the water inlet holes. In the liquid flow channel, this can not only ensure that the upper liquid flow flows into the flowmeter for measurement, but also ensure the thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com