A wind turbine generator high-speed shaft dynamic centering monitoring method and system

A technology for wind turbines and high-speed shafts is applied in the monitoring of wind turbines, control of wind turbines, wind turbines, etc. It can solve the problems of inability to monitor the dynamic alignment state and poor reliability of the operation of the unit, and reduce and improve the deviation value. Operational reliability and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

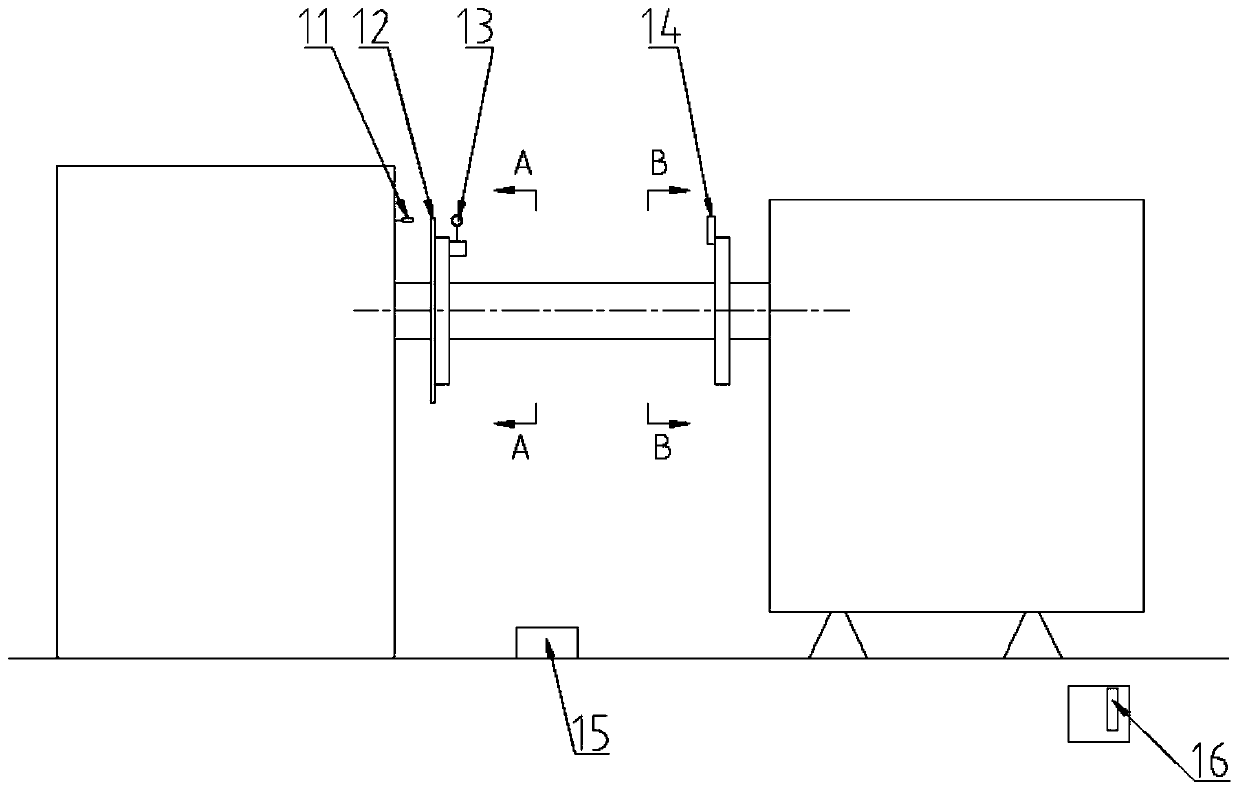

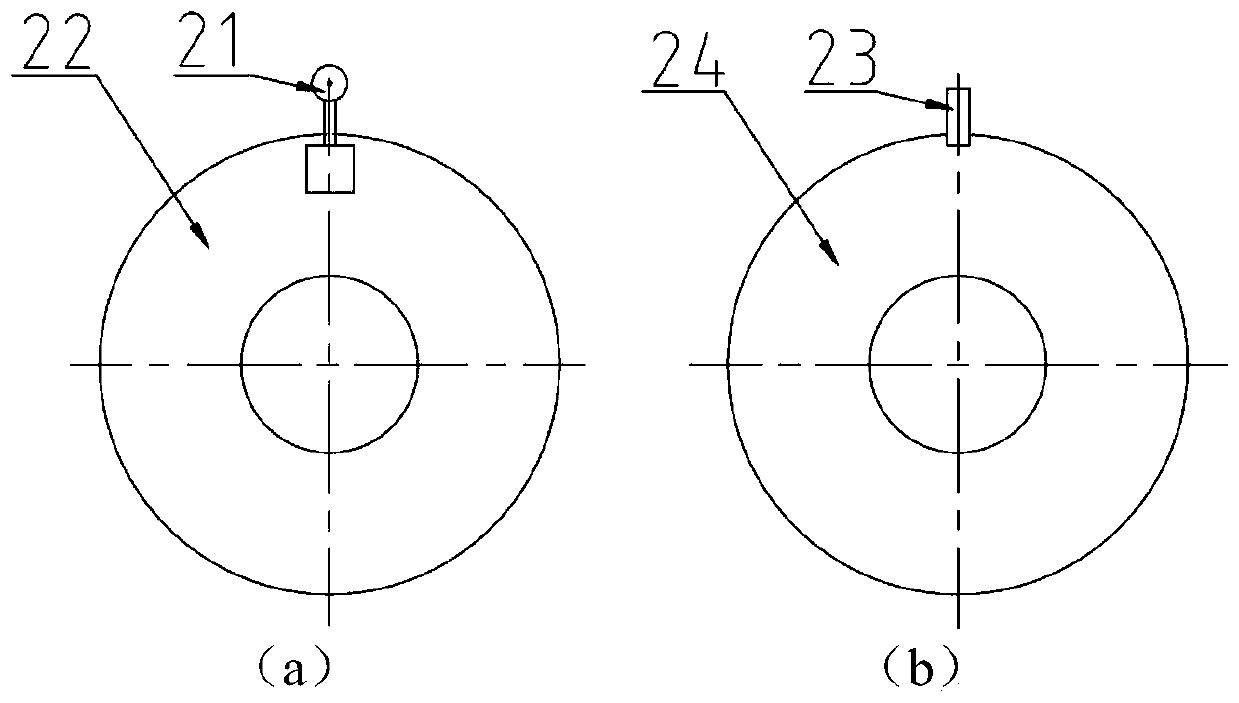

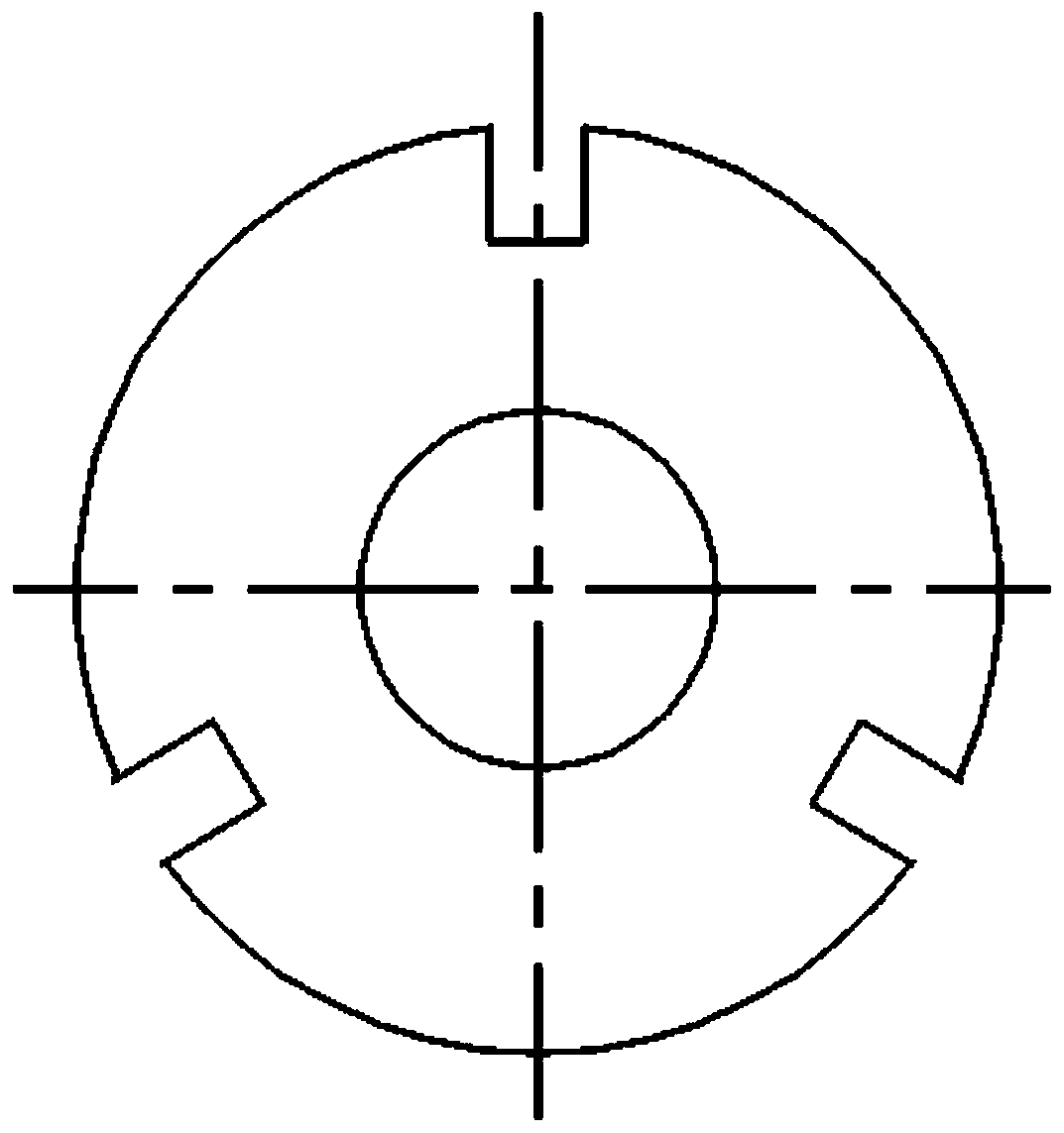

[0032] refer to Figure 1 to Figure 5 A method for dynamic centering of a high-speed shaft of a wind power generating set, the method comprising the following steps:

[0033] a) Set pulse trigger device and alignment detection device on the high-speed shaft of the gearbox;

[0034] b) Use the periodic pulse signal generated by the pulse trigger device to trigger the high-speed shaft alignment detection device of the wind turbine to measure the alignment data;

[0035] c) The high-speed shaft of the wind turbine unit measures the alignment data for a set number of times per rotation, and transmits the alignment data to the signal processing module through wireless transmission;

[0036] d) The signal processing module analyzes the measurement data to obtain the measured deviation values Δx, Δy, and Δθ. By comparing the measured deviation with the preset allowable de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com