Dynamic control system and method for opening target value of secondary air damper of boiler

A secondary air baffle and dynamic control technology, which is applied in the direction of combustion control, combustion method, and air supply adjustment, can solve problems such as elongated combustion process, changes in steam temperature parameters, unfavorable boiler safety and economy, and achieve Effect of improving steam temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in further detail below in conjunction with accompanying drawing:

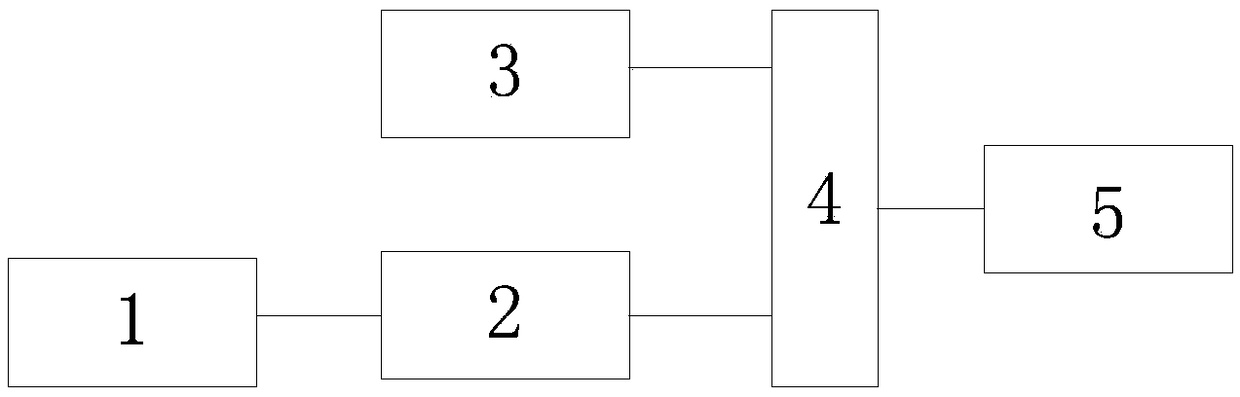

[0013] refer to figure 1 According to this method, the dynamic control system for the opening degree target value of the secondary air baffle according to the present invention includes a controller 5, an adder 4, and a first control logic module for generating a preset value of the opening degree of the reference secondary air baffle 3. The second logic control module 2 for generating the preset value of the opening of the additional secondary wind baffle, and the acquisition module 1 for collecting the AGC instruction issued by the electric energy management system; the output terminal of the acquisition module 1 is connected to the first The input of the two logic control modules 2 is connected, the output of the second logic control module 2 is connected with the output of the first control logic module 3 and the input of the adder 4, and the output of the adder 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com