Test machine cabinet

A cabinet, to-be-tested technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of waste of economy and site utilization, prone to unstable contact, large occupied volume, etc., to improve aging efficiency, Improve test efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

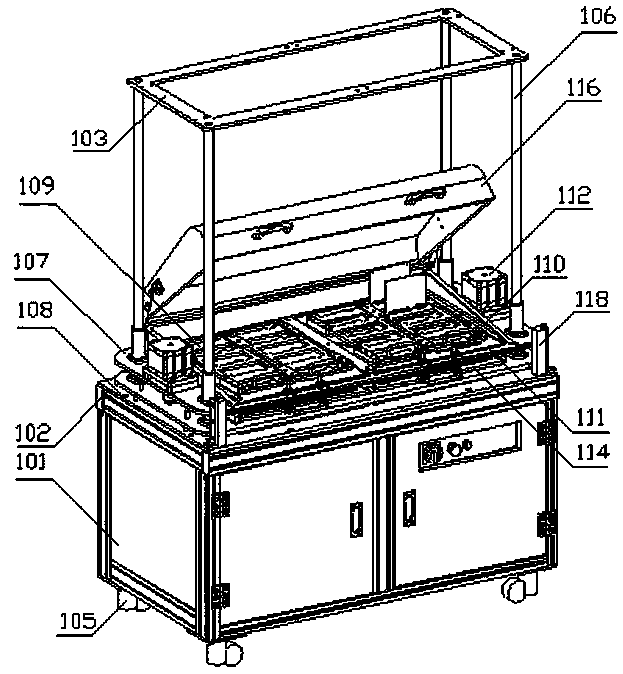

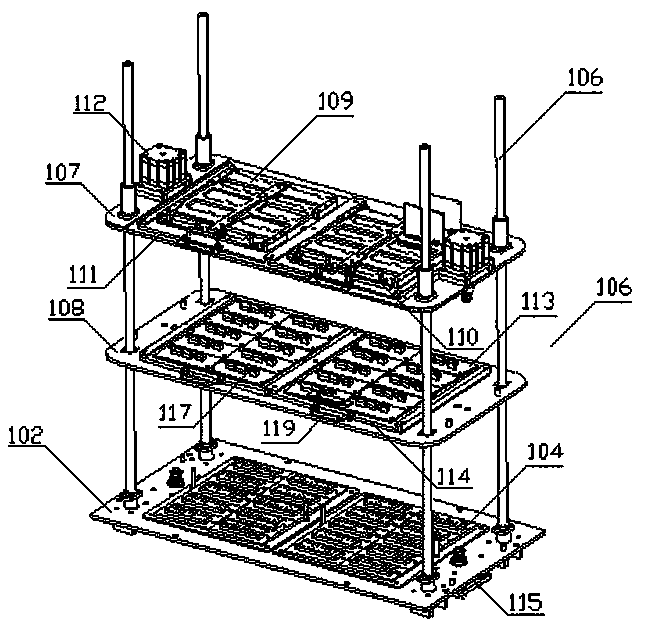

[0030] Such as figure 1 and figure 2As shown, a test cabinet includes a test box 101 with an open upper end, a fixed plate 102, a connecting plate, a heating shield 116 and a top plate 103, the fixed plate 102 is covered on the upper end of the test box 101, and the fixed plate 102 is provided with a thimble base plate 104 on the upper surface, the lower surface of the fixed plate 102 is provided with a first adapter plate, the four peripheral corners of the fixed plate 102 are respectively provided with guide rods 106, and the four peripheral corners of the connecting plate are respectively provided with guide rods 106. The corners are respectively sleeved in the middle of the corresponding guide rods 106, and mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com