Toner cartridge of novel magnetic roller

A magnetic roller and toner cartridge technology, which is applied in the electric recording process applying charge pattern, the equipment of electric recording process applying electric charge pattern, electric recording technique, etc. Problems such as deformation of metal spacers, saving man-hours and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

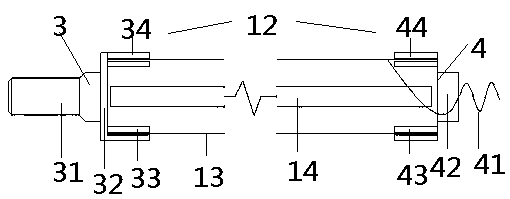

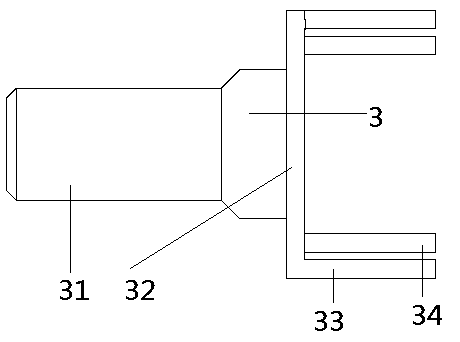

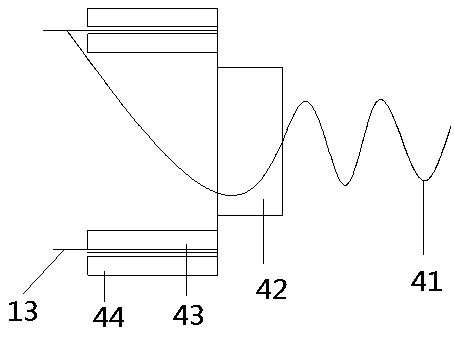

[0007] Below in conjunction with accompanying drawing, the present invention is described in detail: with reference to accompanying drawing figure 1 , attached figure 2 And attached image 3 , a novel magnetic roller toner cartridge, comprising a waste toner bin 2, a cleaning blade 23, a charging roller 22, a photosensitive drum 21, a powder scraper 17, a powder bin 1, a magnetic roller 12 and toner 18. The waste toner bin 2 is a part of the shell structure of the toner cartridge, on which a cleaning scraper 23, a charging roller 22 and a photosensitive drum 21 are installed; Roller 12 and toner 18; waste toner bin 2 and powder bin 1 form a toner cartridge. The magnetic roller includes a magnetic core 14 , a magnetic sleeve 13 , a rubber head 4 at a conductive end, and a rubber head 3 at a gear end. The magnetic core 14 is a cylindrical magnetic rod, the magnetic sleeve 13 is a circular aluminum tube coated with an adsorption layer, the magnetic core 14 is installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com