Square lithium battery inspection machine

A lithium battery and inspection machine technology, which is applied in the use/repair of primary batteries, secondary battery testing, and secondary battery repair/maintenance, etc., can solve the problems of time-consuming and laborious operation, low inspection efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Combine below Figure 1-Figure 17 The present invention is further described.

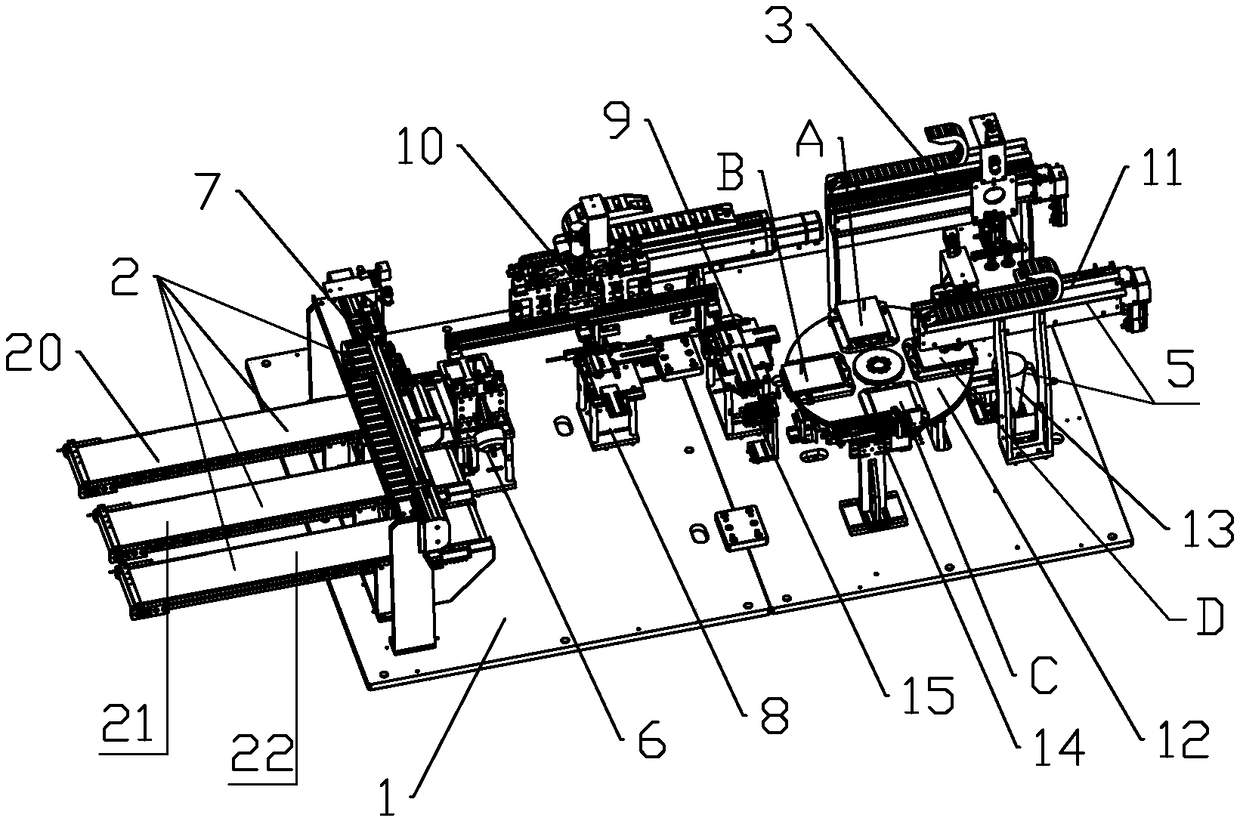

[0055] Such as Figure 1-Figure 17 The shown square lithium battery inspection machine includes a frame 1, a turntable mechanism 12, a cell testing mechanism 15, a connector separation mechanism 14, a code scanning mechanism 5, a first unqualified conveying mechanism 3, a length measuring mechanism 9, Width measuring mechanism 8 , thickness measuring mechanism 6 , linkage manipulator 10 and discharging mechanism 2 .

[0056] The frame 1 includes a frame main structure and an air pump triple, and the bottom of the frame main structure is provided with universal wheels and anchor screws. The air pump triple is used to provide the power source for the pneumatic components in the equipment.

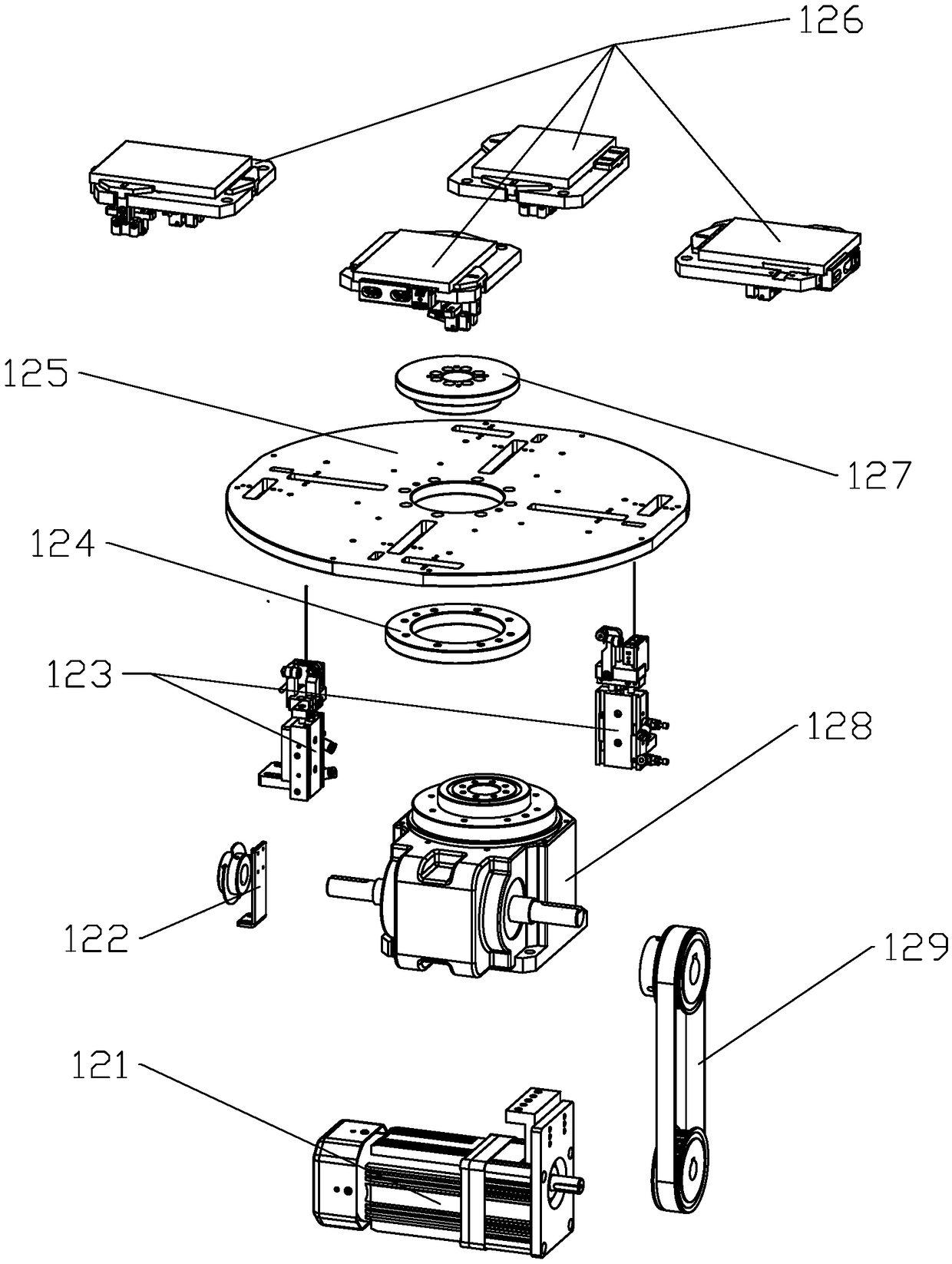

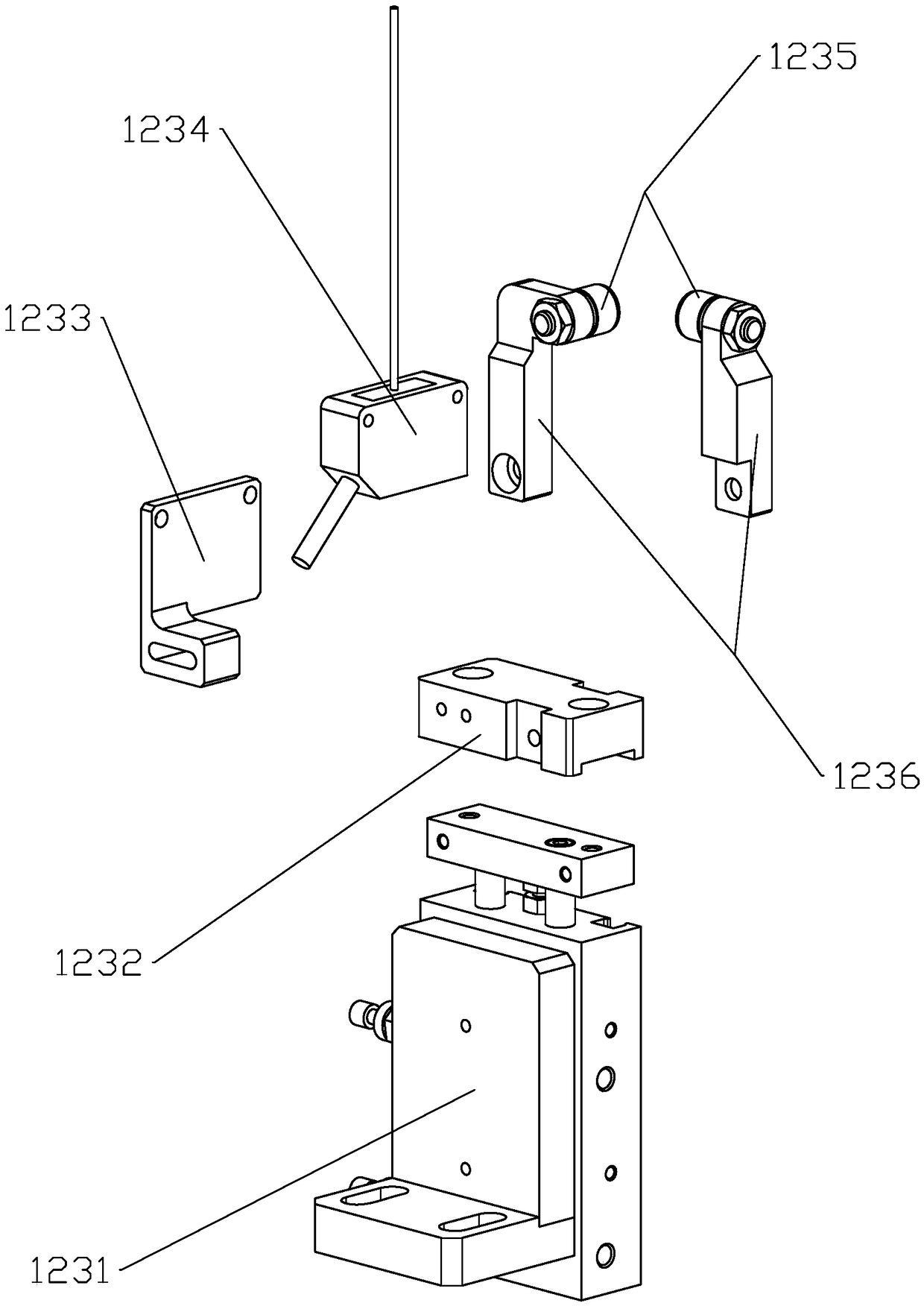

[0057] The turntable mechanism 12 is used to drive the battery to move, so as to adapt to the operation of the battery by the cell test mechanism 15, the connector separation mechanism 14 and the code sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com