Spray room sludge separator

A technology for separating machines and sludge, which is applied to centrifuges and centrifuges with rotating drums, etc. It can solve the problems of increasing the workload of workers and affecting the working efficiency of machines, and achieves convenient and quick disassembly and assembly, reducing resistance, The effect of reducing kinetic energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

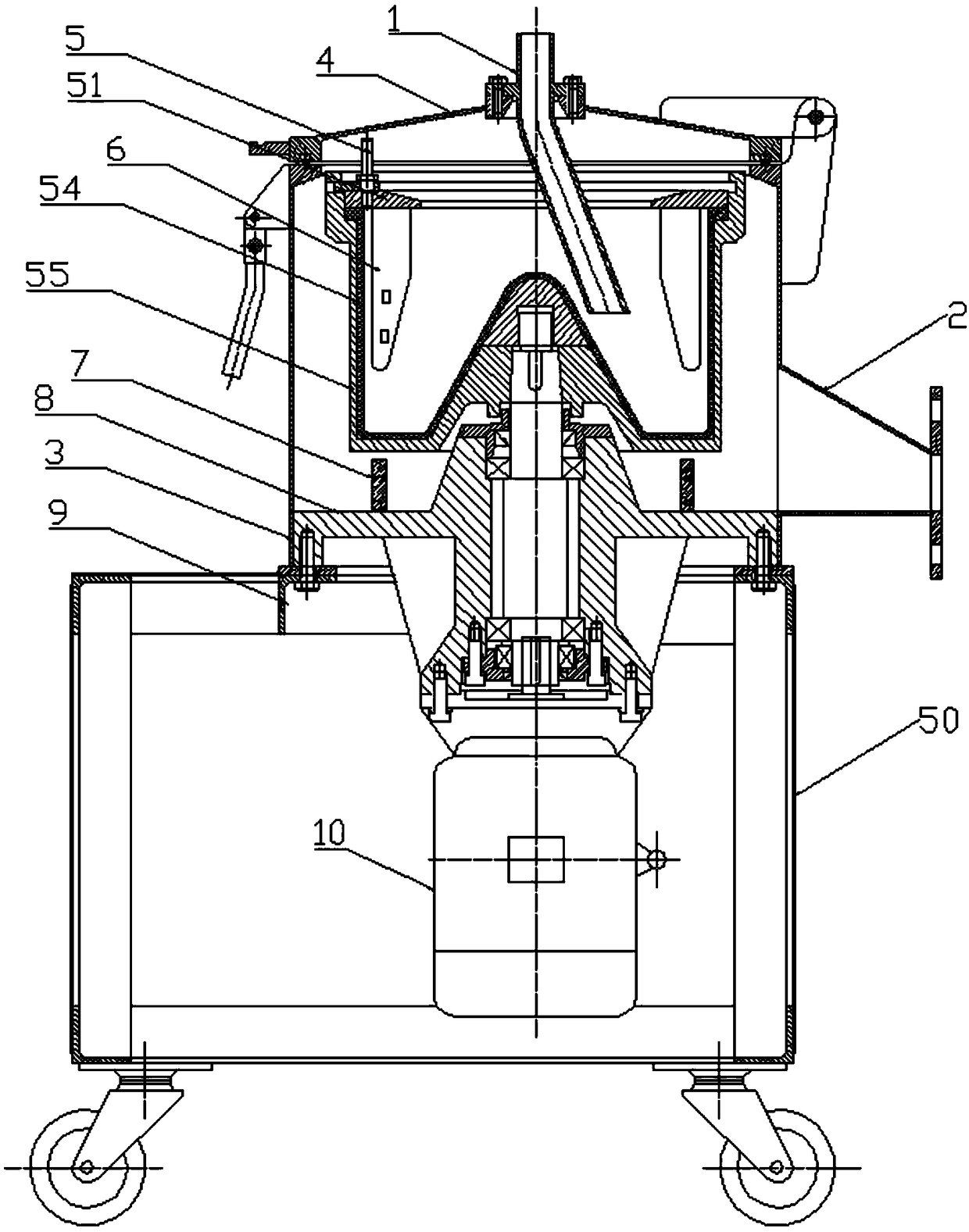

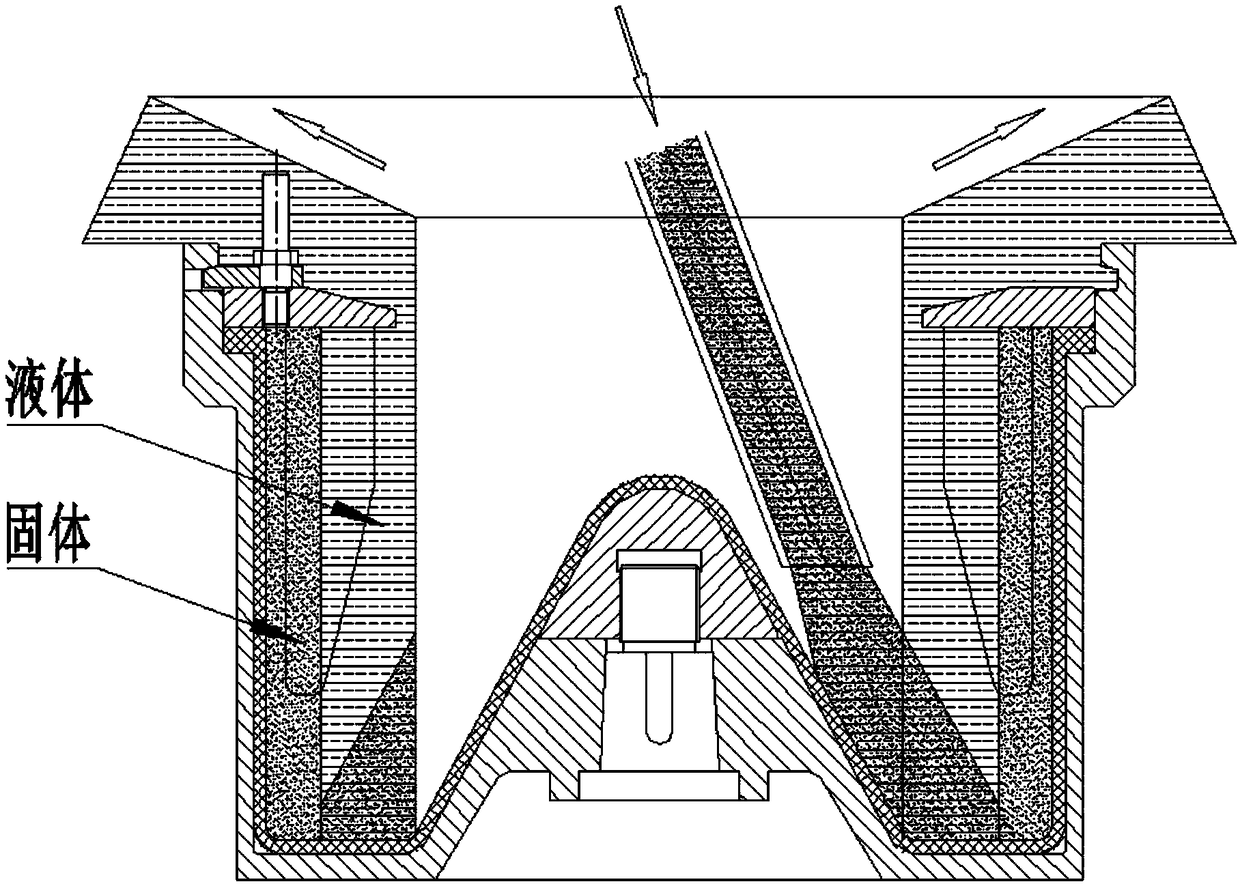

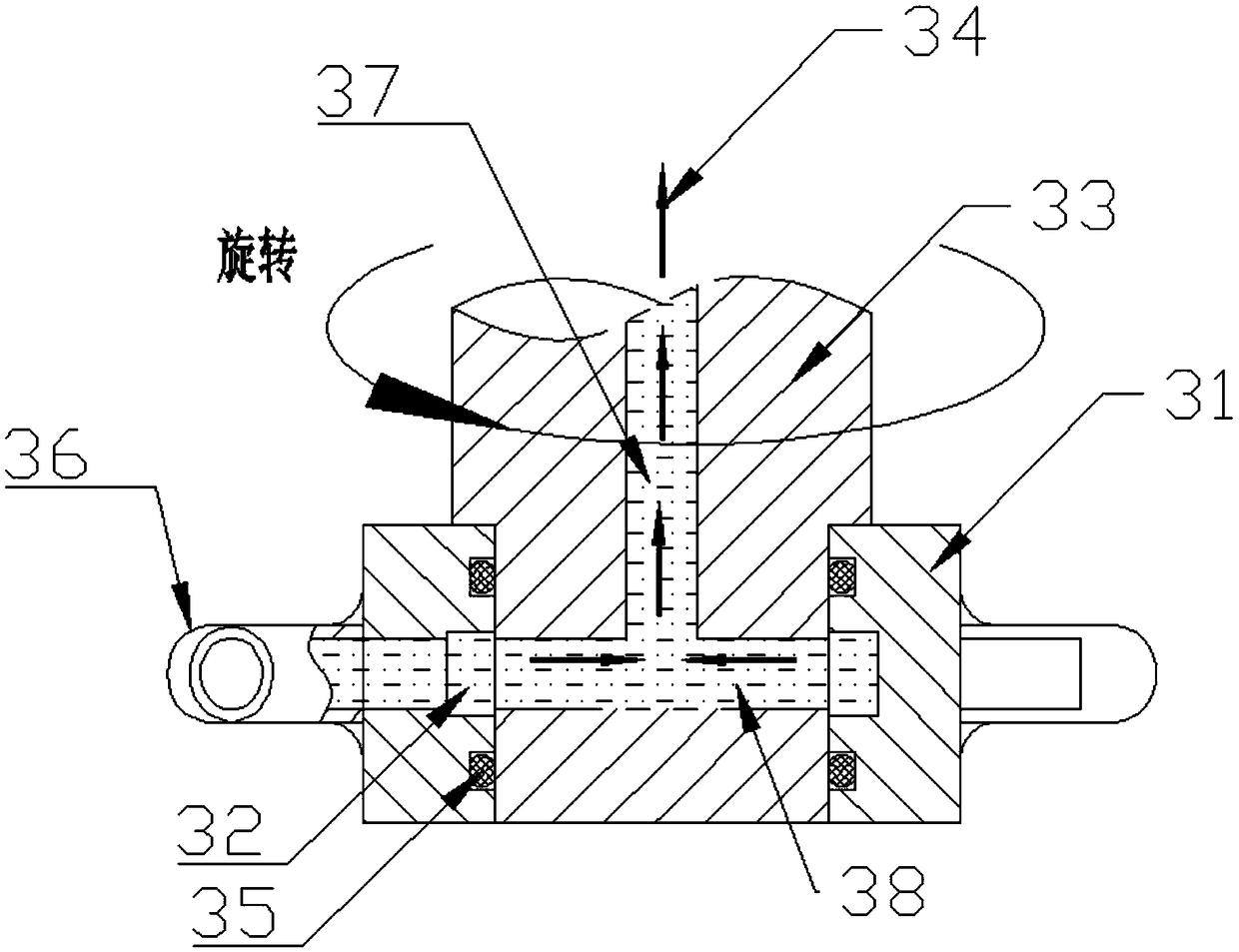

[0035]In order to achieve the purpose of the present invention, one embodiment of the present invention is: a spray booth sludge separator, including a machine base 9, a casing 3, a drum 55 and a driving device, and an organic cover 4 is installed on the casing 3 , a feeding pipe 1 is connected on the machine cover, the drum 55 is driven by the driving device, and the driving device is installed on the machine base 9, a waste liquid recovery chamber is formed between the housing 3 and the drum 55, and one side of the housing 3 is provided There is a liquid discharge port 2, a barrel 54 is installed in the drum 55, a liquid blocking plate 51 is detachably installed on the barrel 54, and at least one synchronous baffle 6 is installed on the liquid blocking plate 51, and the synchronous baffle 6 is installed There is a signal generator capable of detecting full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com