Comprehensive treatment system for belt gallery

A comprehensive treatment and belt technology, which is applied in the comprehensive treatment system field of belt corridors, can solve problems such as noise and dust pollution, dust pollution, excessive noise in belt corridors, etc., to solve the problems of noise pollution and dust pollution, Easy installation and maintenance, easy disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

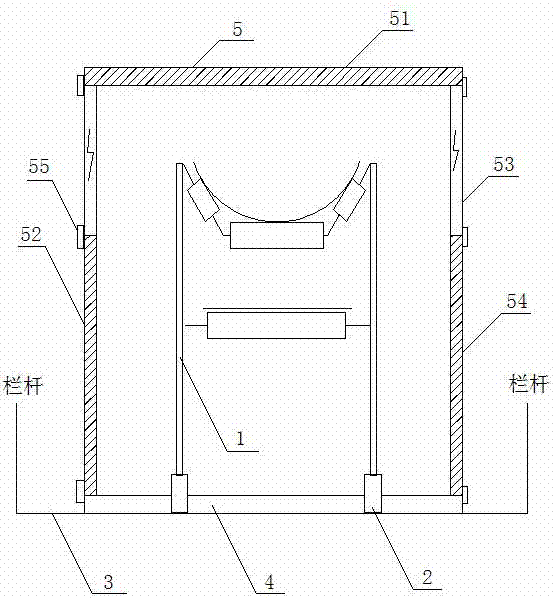

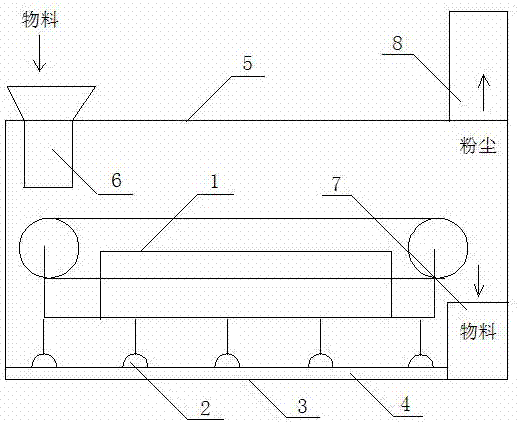

[0017] Such as figure 1 , 2 As shown, a comprehensive treatment system for belt corridors, including a number of vibration dampers 2 installed under the belt rack 1, sound insulation and energy consumption panels 4 installed on the corridor floor 3, and belt conveyors are included The belt suction and sound insulation frame 5, the feed sound-absorbing frame 6 located at the joint of the belt head, the discharge sound-absorbing frame 7 located at the lower part of the belt outlet, and the dust collector sound-absorbing frame 8 located at the upper part of the belt outlet; The dust in the closed belt suction and sound insulation frame is sucked away for dust removal treatment, and the noise is absorbed and reduced by the feed sound silencer frame, the discharge sound silencer frame, the belt suction sound insulation frame and the sound insulation energy consumption plate, and the belt conveyor is eliminated by the vibration damper. Vibration noise to corridor floors.

[0018] ...

Embodiment 2

[0020] As a preferred design of Embodiment 1, in actual use, although elastic damping elements, such as springs, can eliminate vibration, there is still a certain amount of solid-state sound transmission. Therefore, the present invention prefers an air-filled damping element.

[0021] The gas-filled shock absorber is an air bag with connecting plates at both ends.

[0022] As another design of the gas-filled shock absorber,

[0023] The pneumatic shock absorber is a pneumatic wheel with a connecting shaft in the middle. Such as inflated rubber tires.

[0024] The air-filled shock absorber can well solve the vibration and mechanical noise. From the perspective of processing general parts, the processing cost of choosing pneumatic rubber tires is the lowest, the noise reduction effect can meet the requirements of this application, and the cost performance is the highest.

Embodiment 3

[0026] As the design of the sound insulation and energy consumption layer in Embodiments 1 and 2, the sound insulation and energy dissipation board is composed of a sound insulation layer, an energy dissipation layer or a sound insulation layer, an energy dissipation layer, and a sound insulation layer. It consists of the energy-dissipating layer keel and the energy-dissipating material inside the keel. The choice of sound-absorbing cotton as an energy-dissipating material can attenuate the energy of sound transmission and prevent the transmission of solids caused by a single sound-insulating layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com