Sandwich type dispensing equipment and dispensing method thereof

A sandwich-type, glue-dispensing technology, which is applied in coatings and devices for coating liquid on the surface, can solve problems such as air bubbles in the interlayer of flexible substrates, so as to improve competitive advantages, meet quality requirements, and improve production yields. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

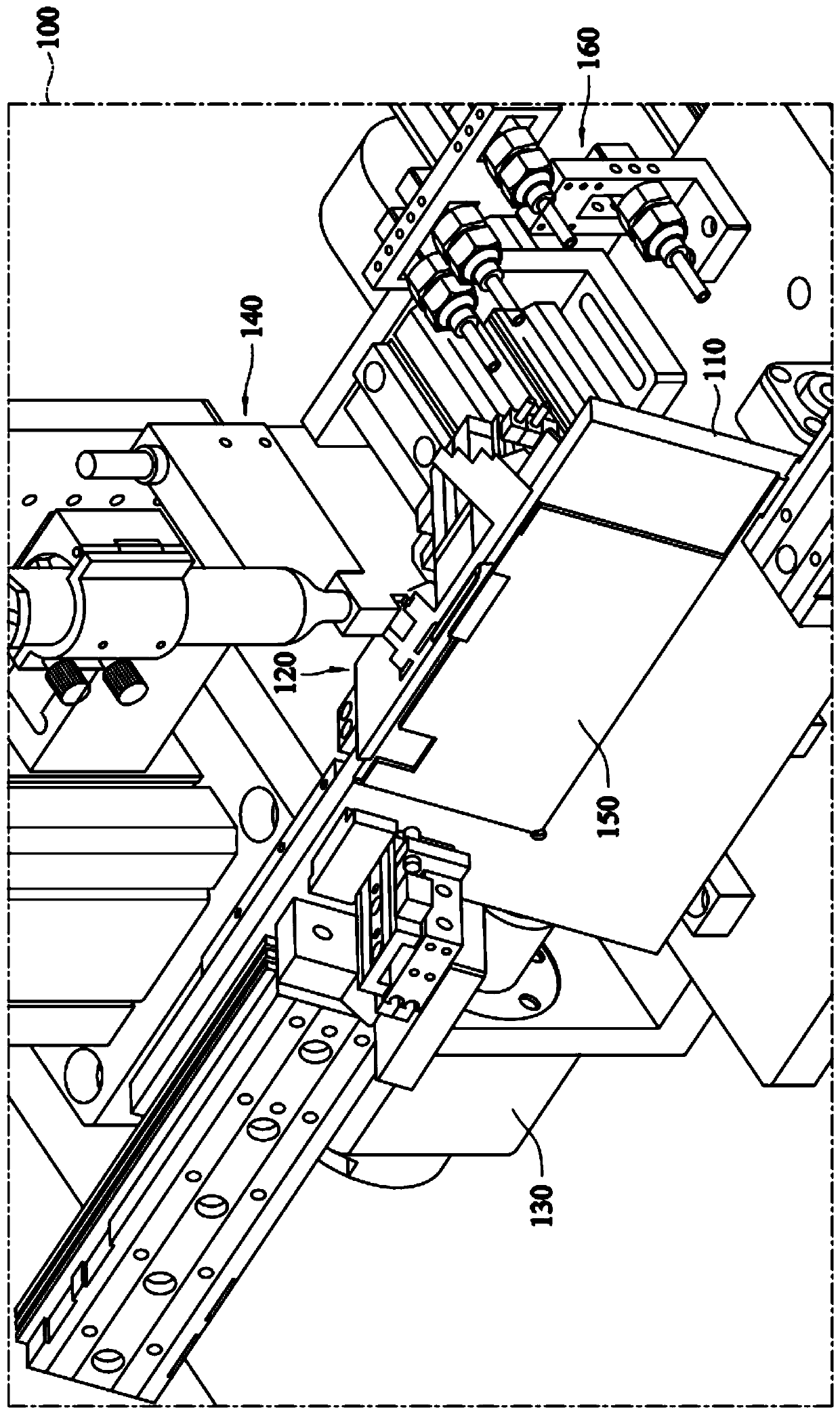

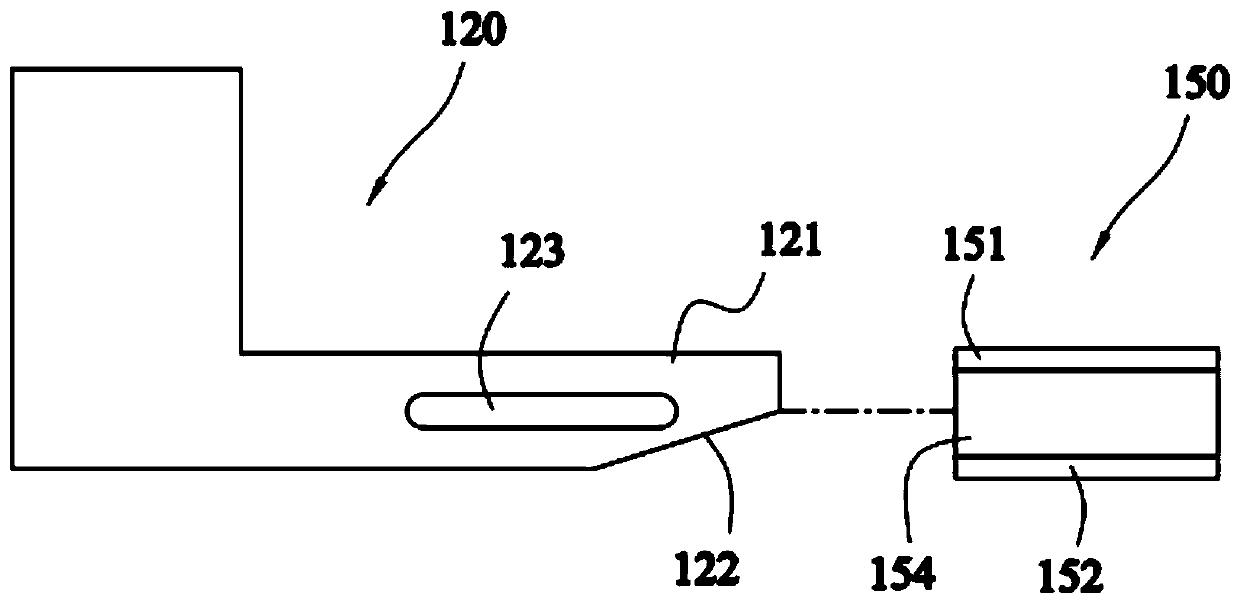

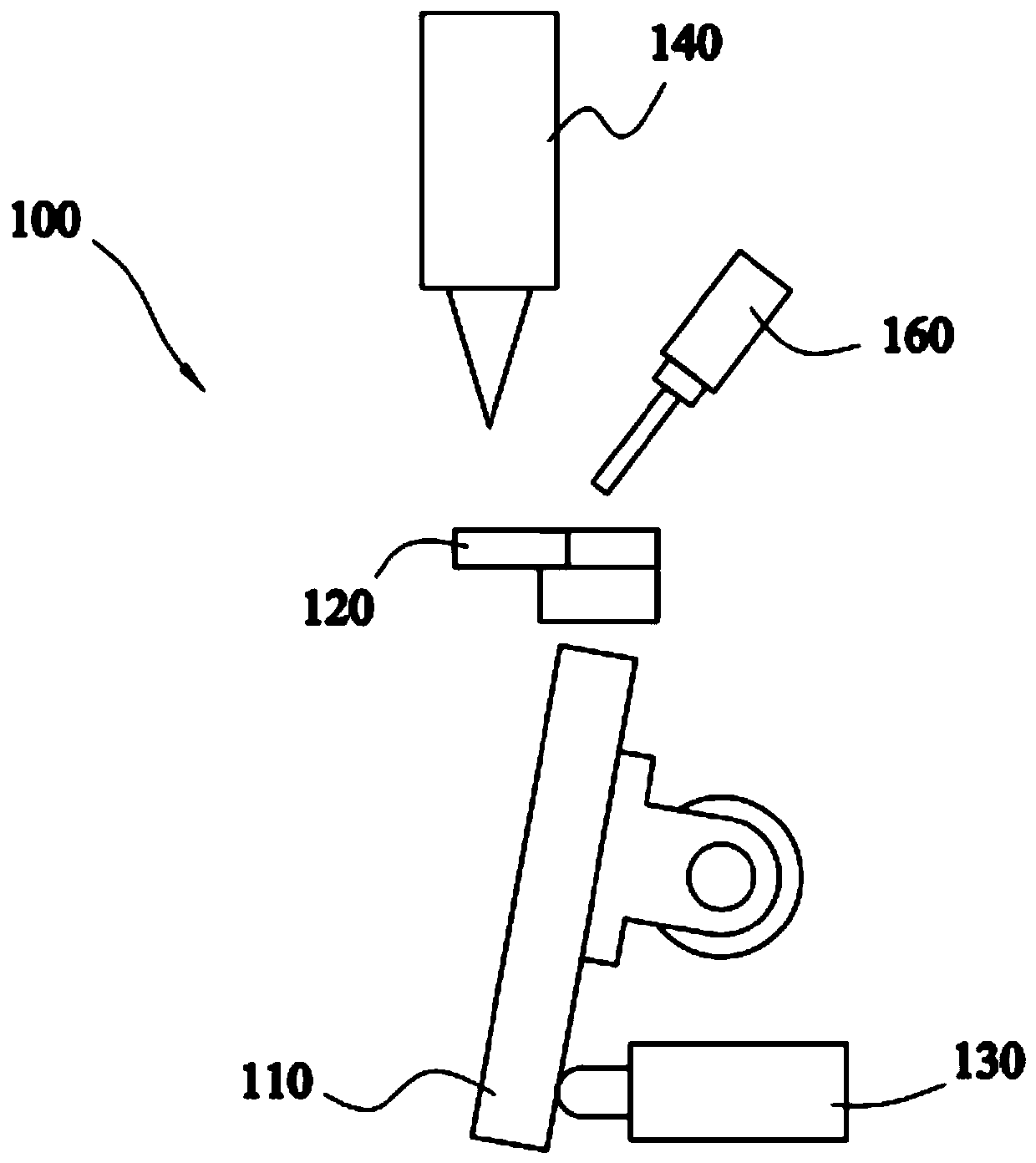

[0031] Please refer to figure 1 , which shows the schematic diagram of the sandwich type dispensing equipment provided by the embodiment of the present invention; please refer to Figure 2A , which shows a schematic diagram of the relative relationship before the separation rod of the separation jig in the sandwich type dispensing equipment provided by the embodiment of the present invention is inserted into the sandwich structure; at the same time, please refer to Figure 2B , which shows a schematic diagram of the sandwich type dispensing equipment provided by the embodiment of the present invention, wherein the separation rod of the separation jig has been inserted into the sandwich structure. In order to clearly show the present invention, some elements in the figure are omitted.

[0032] In this embodiment, the sandwich type glue dispensing device 100 is mainly composed of a carrying platform 110 , a separation mechanism 120 , an angle positioning mechanism 130 and a glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com