Semiconductor package with contact support layer and method to produce the package

A technology of semiconductors and semiconductor tubes, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as unreliability and complicated methods, and achieve reliable support, simple and fast methods, and support layers Simple and Flexible Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

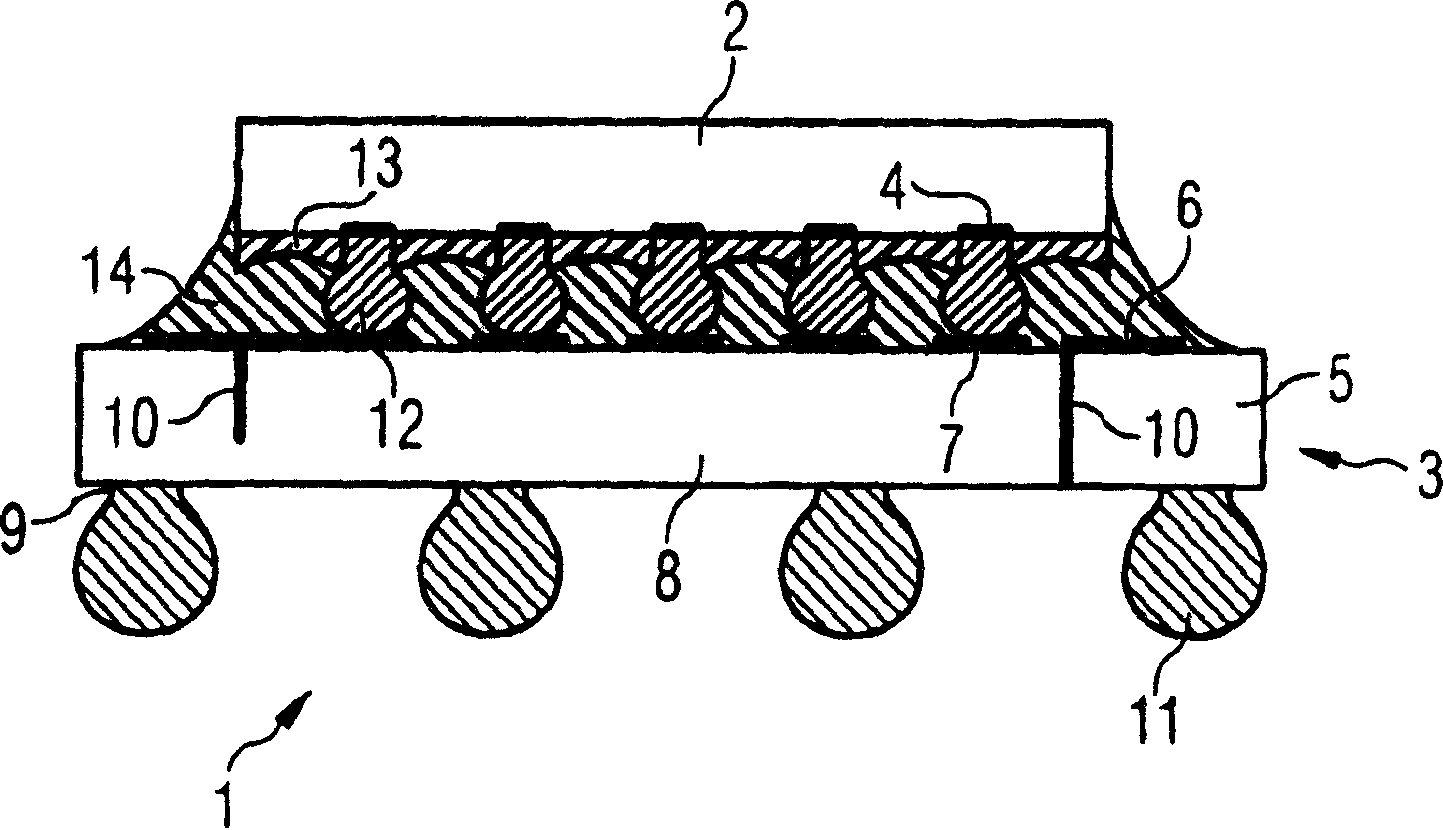

[0036] figure 1 Shown is a cross-sectional view of a semiconductor package 1 comprising a semiconductor die 2 mounted to a redistribution plate 3 by flip-chip technology.

[0037] Semiconductor die 2 includes an active surface including a plurality of die contact pads 4 and a passive surface. The redistribution plate 3 comprises a sheet of non-conductive core material 5 and includes a plurality of upper conductive traces 6 and upper contact pads 7 on its upper surface and a plurality of lower conductive traces 8 and external contacts on its bottom surface. District 9. The redistribution plate 3 also includes a plurality of substantially vertical conductive vias 10 electrically connecting the upper contact pads 7 with the contact areas 9 on the bottom surface of the redistribution plate 3 . Solder balls 11 are attached to the external contact areas 9 to provide an electrical connection from the package 1 to an external circuit board (which is not shown in the figure).

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com