Vertical casting and flow guiding device for workpiece and casting method of device

A diversion device, vertical technology, applied in the field of vertical casting diversion devices for workpieces, can solve problems such as difficulty in controlling the casting quality of workpieces, achieve the effects of avoiding inclusions, convenient operation, and improving success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

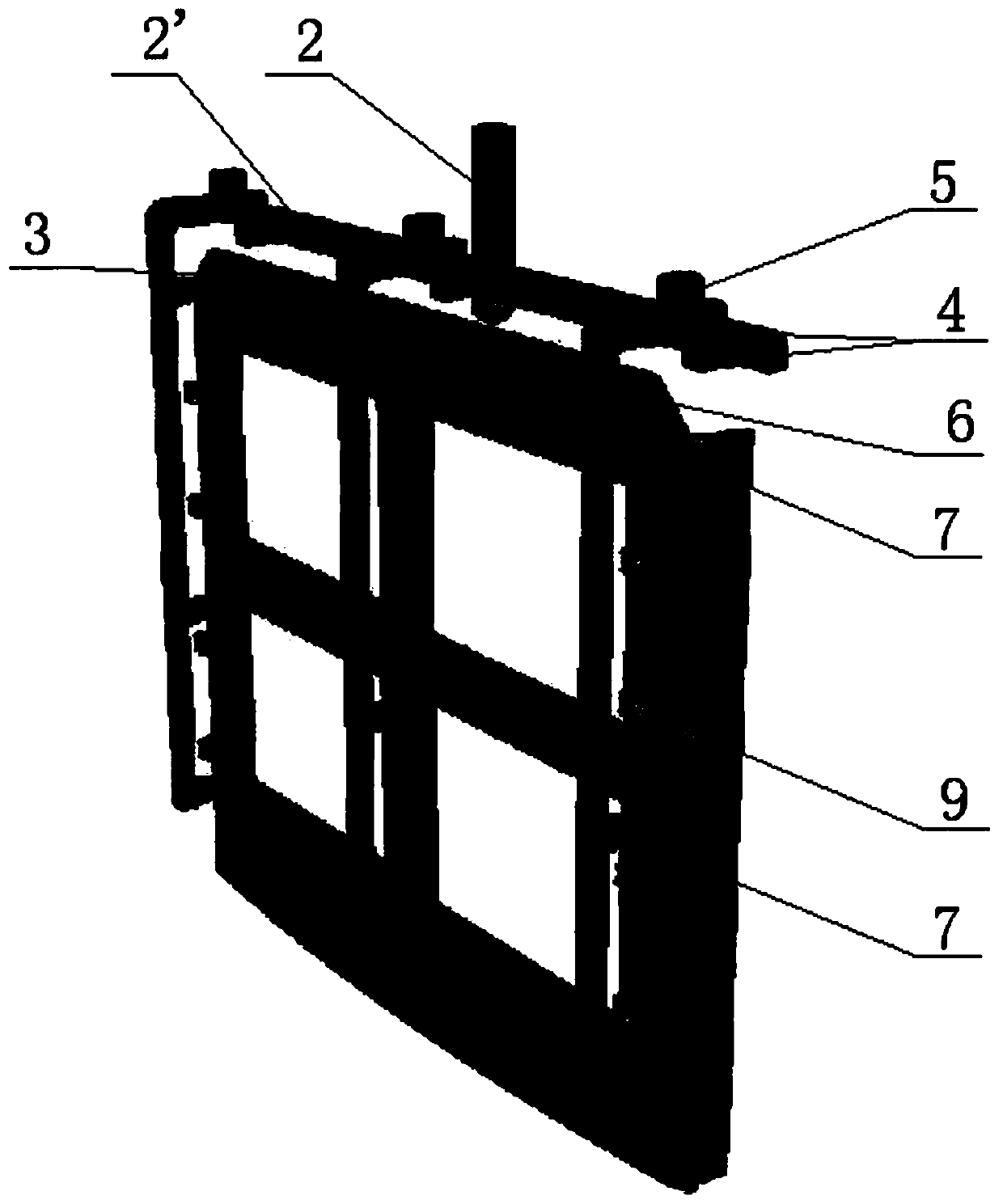

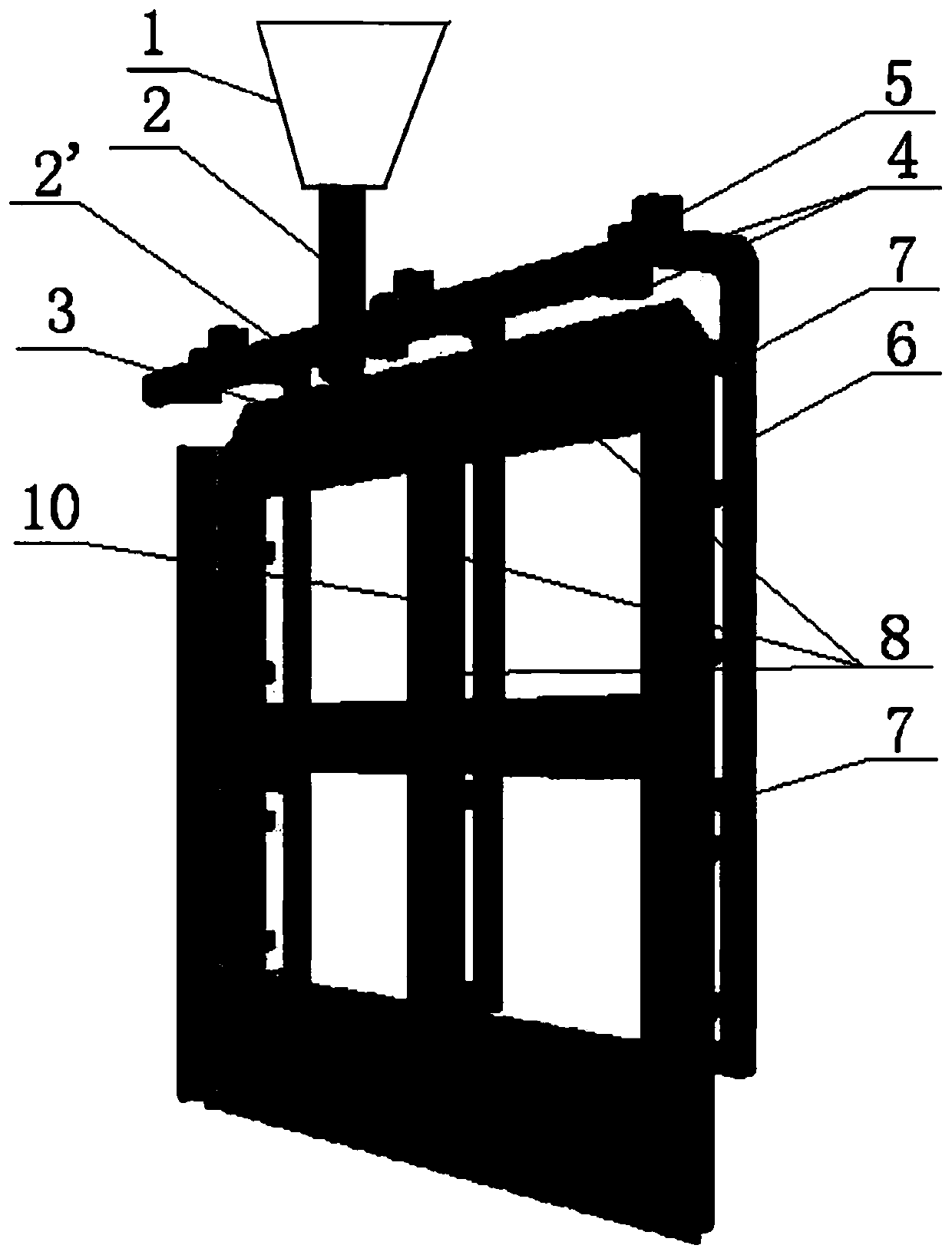

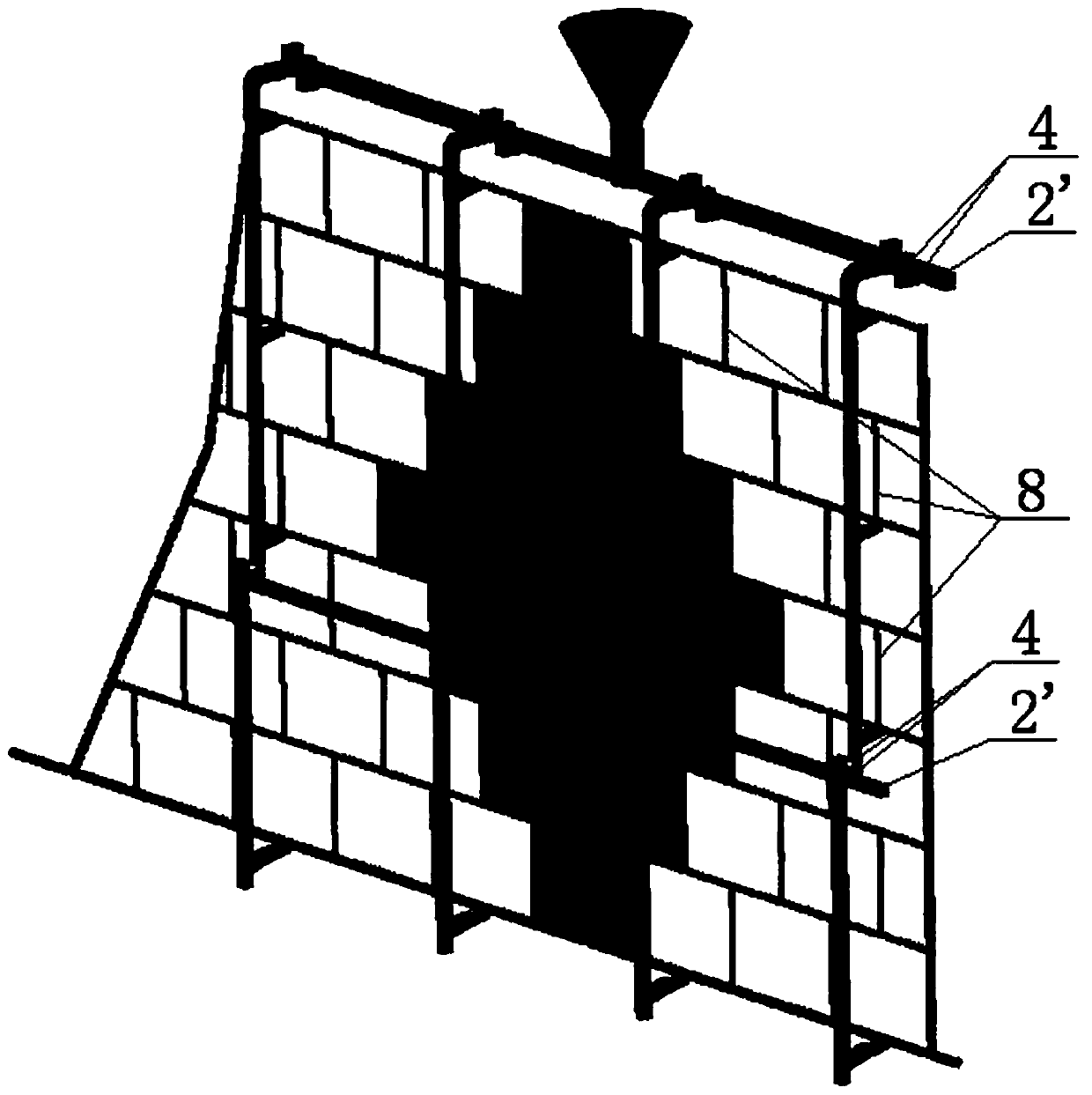

[0034] In the description of the drawings, the number 1 is the casting hopper, 2 is the main casting pipe, 2' is the liquid distribution pipe for casting, 3 is the base plate, 4 is the liquid level equalization pipe, 5 is the slag chamber, 6 is the vertical casting conduit, and 7 is the liquid 8 is a liquid guide pipe, 9 is a fixed ear, 10 is a casting liquid outlet, 11 is a workpiece, 12 is a fixed snap ring, and 13 is a fastening bolt.

[0035] In the design idea of using the present invention to make workpieces (especially cast iron gates with patterns as the design focus), the following technical difficulties need to be considered:

[0036] 1. When designing patterns, it is necessary to inquire and refer to the relevant information of traditional totem patterns in various countries, and then combine the structure of our country's iron gates to design a shape suitable for our houses.

[0037]2. To design the mold, first of all, calculate the height, width, length of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com