Silicon block prefabricated structure for assembling solar cells

A technology of solar cells and prefabricated structures, applied in the field of solar cells, can solve problems such as unqualified silicon blocks, and achieve the effect of convenient oblique cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

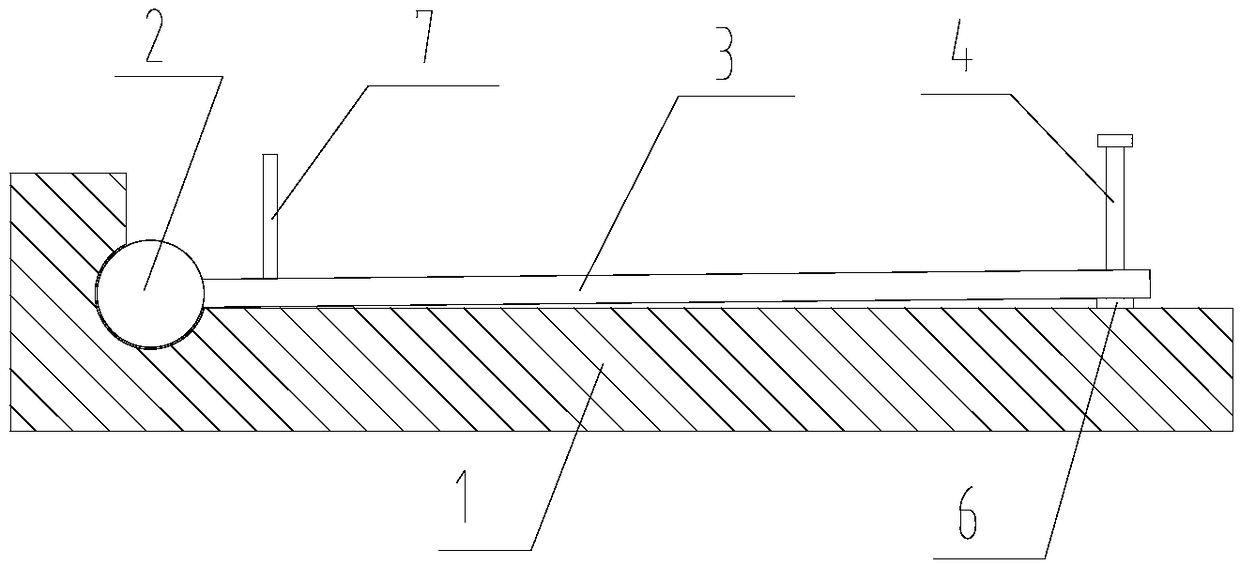

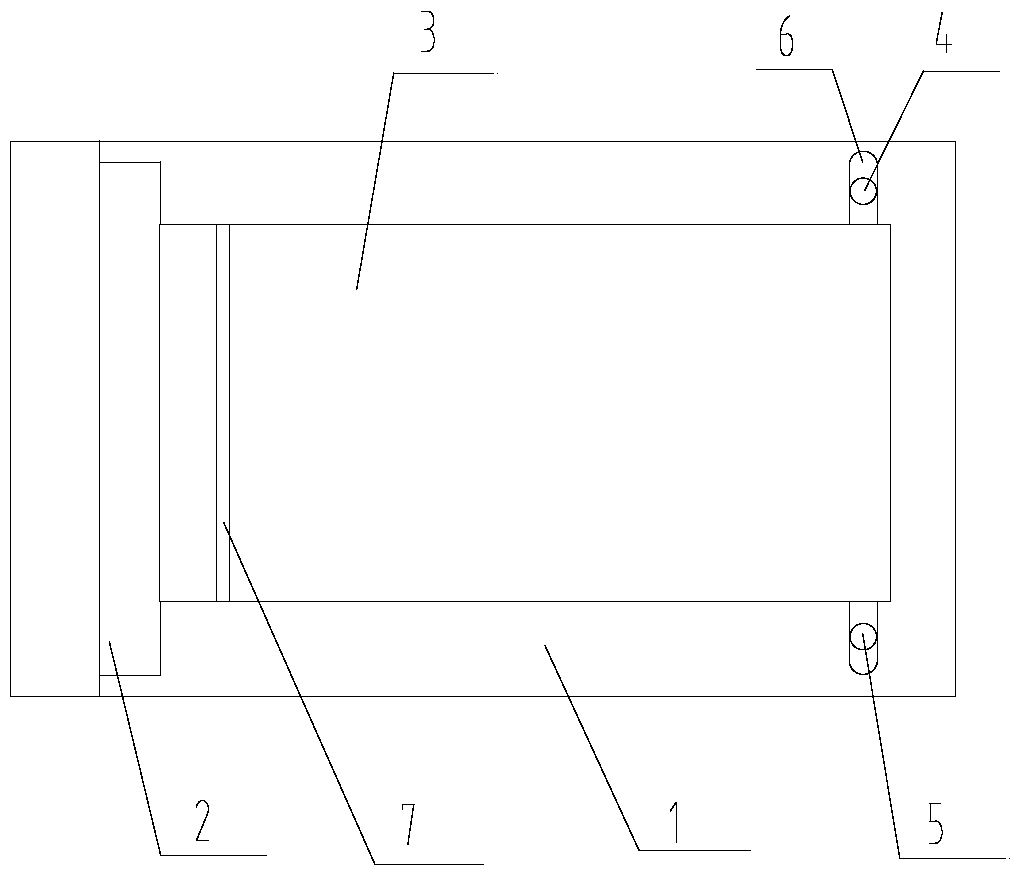

[0017] refer to figure 1 , a silicon block prefabricated structure for assembling solar cells proposed by the present invention includes a base 1 , a rotating shaft 2 , a mounting plate 3 , a first screw 4 , a second screw 5 and a supporting plate 6 .

[0018] The base 1 adopts an L-shaped structure, and its corner is provided with a groove whose inner surface is an arc surface, and the projection of the inner surface of the groove on a plane perpendicular to the length direction of the groove is such that the central angle is greater than 180 degrees and less than 270 degrees. arc. Rotating shaft 2 is installed in the groove. In this embodiment, the rotating shaft 2 is matched with the groove, and both ends of the groove are sealed to prevent the rotating shaft 2 from sliding linearly in the groove. At the same time, the groove covers the rotating shaft 2 to ensure the stable rotation of the rotating shaft 2 in the groove and prevent the rotating shaft 2 from breaking away ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com