Electric injecting table mechanism for double-lead-screw injection

A technology of double screw and injection table, applied in the field of injection molding mechanism, can solve the problems of high cost and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

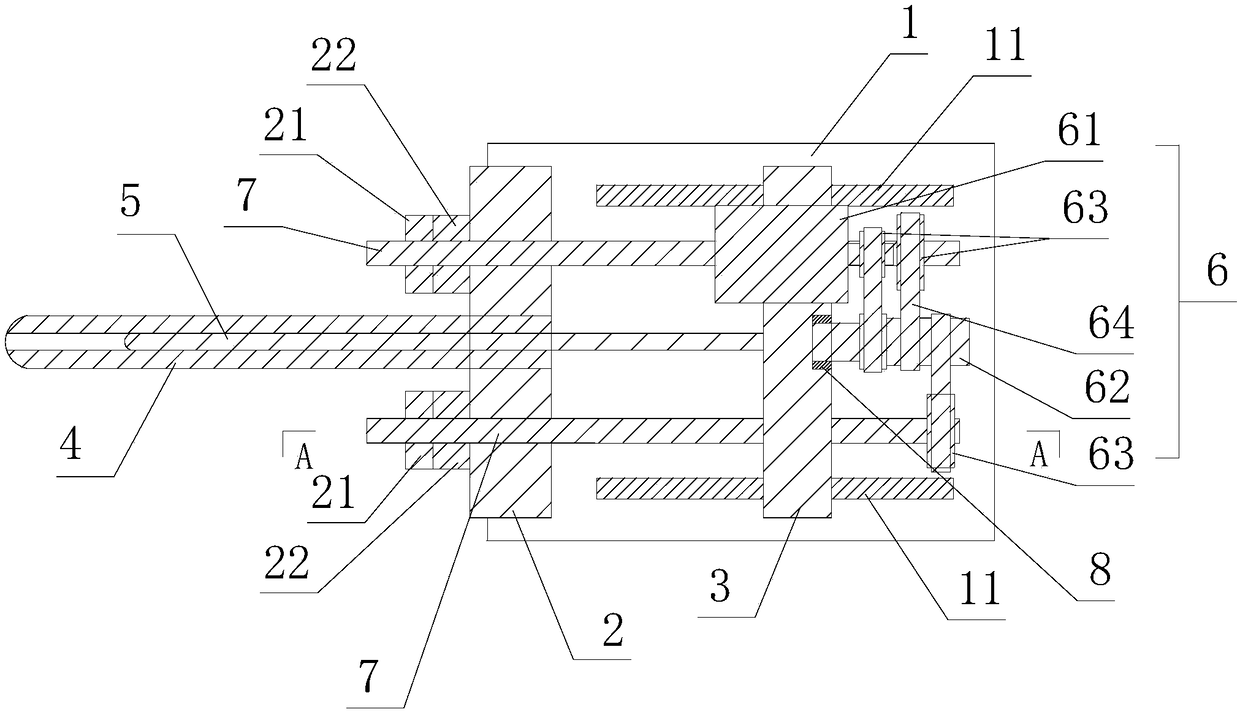

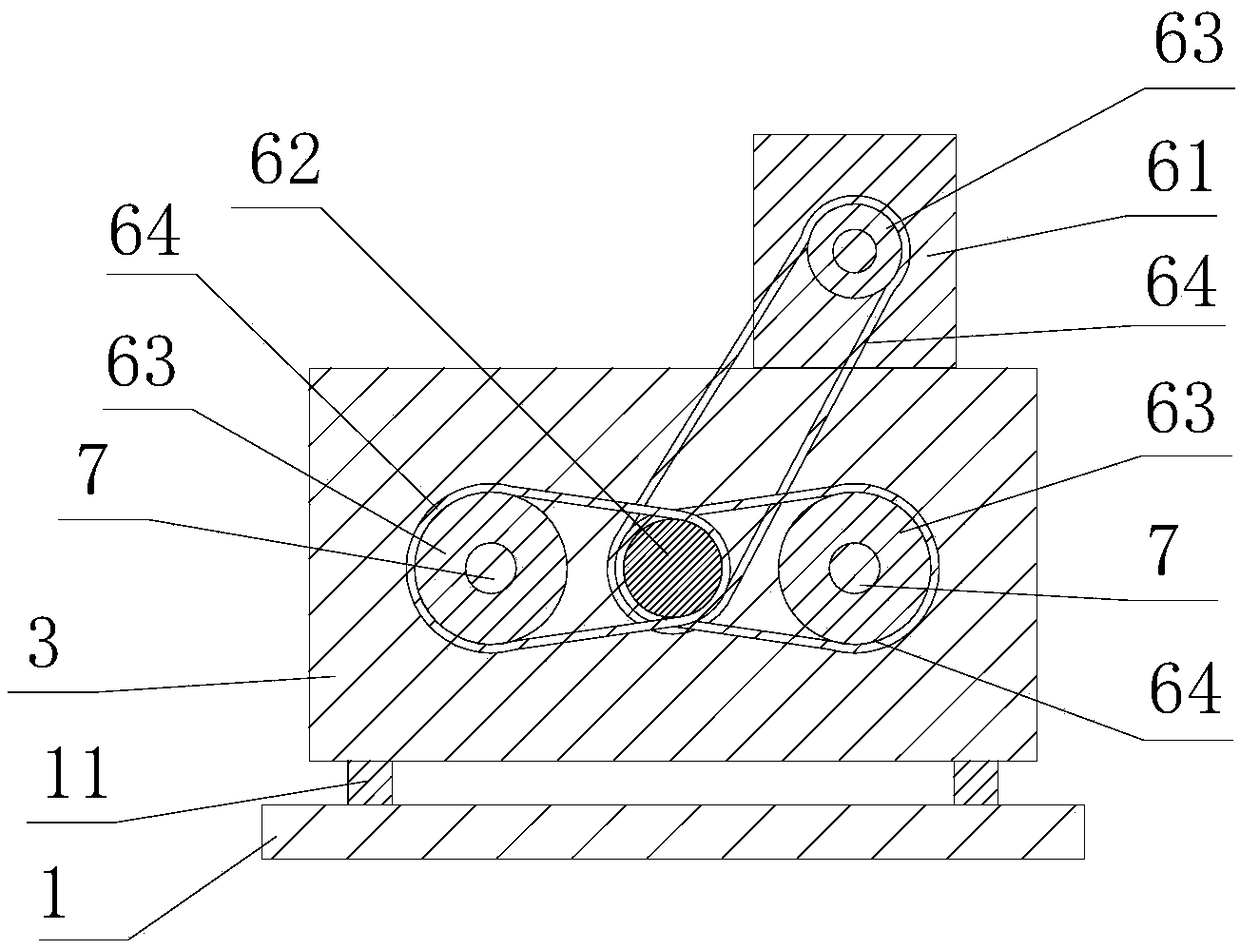

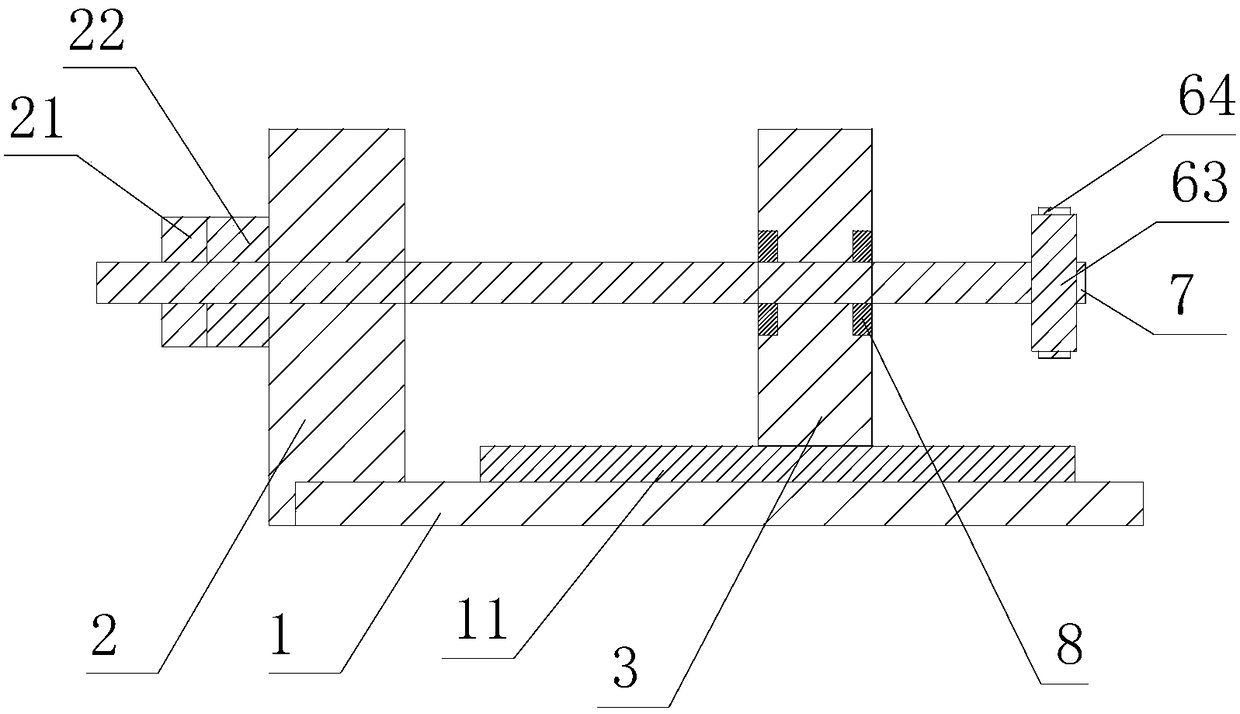

[0018] Such as Figures 1 to 4 As shown, an electric injection platform mechanism for double-screw injection includes an injection platform fixed plate 2 and an injection platform movable plate 3 on a base 1, and a melt rubber cylinder 4 is arranged on the injection platform fixed plate 2, wherein: the injection platform is movable The plate 3 is provided with an electric drive device 6, and the injection platform fixed plate 2 and the injection platform movable plate 3 are provided with an injection screw 5 and ball screws 7 on both sides of the injection screw 5, and the injection screw 5 and ball screws 7 The rotation is positioned in the movable plate 3 of the injection platform, the glue injection screw 5 is interspersed in the melt cylinder 4, the electric drive device 6 is connected with the glue injection screw 5 and the ball screw 7 and rotates simultaneously, the fixed plate 2 of the injection platform is provided with a nut 21, the ball The free end of the screw man...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap