Cement bag breaking equipment

A cement and equipment technology, applied in the field of cement bag breaking equipment, can solve the problems of affecting health and low work efficiency, and achieve the effects of saving manual operation costs, stable transmission ratio, and wide power range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementations.

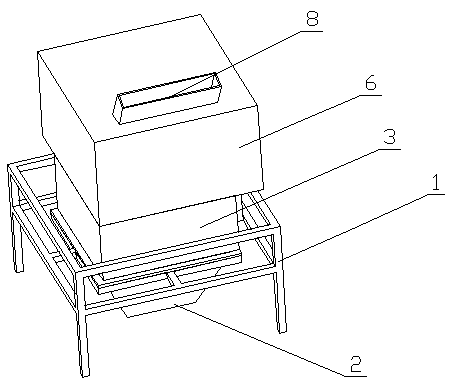

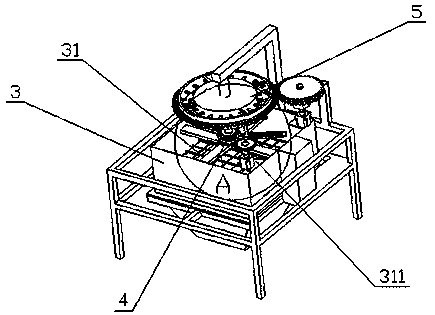

[0028] see Figure 1 to Figure 8 The present invention is: a cement bag breaking equipment, comprising a frame 1, a hopper 2 is arranged on the frame 1, a protective cover 3 is arranged on the upper part of the hopper 2, a gear linkage mechanism 4 is arranged inside the protective cover 3, and the gear linkage The upper part of the mechanism 4 is provided with a tray assembly 5, the tray assembly 5 is arranged on the cantilever of the rack 1, the outer side of the protective cover 3 is provided with a casing 6, and the upper part of the casing 6 is provided with a feeding port 8;

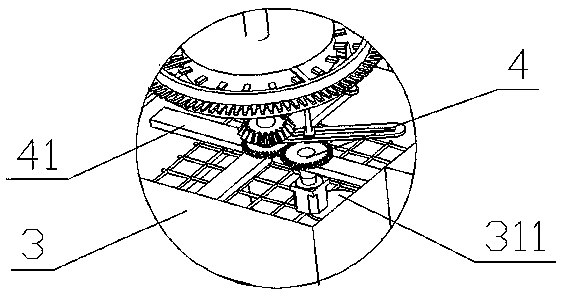

[0029] The gear linkage mechanism 4 includes a receiving frame 41 , a gear transmission system 42 and a connecting rod transmission system 43 . A column pin is arranged in the middle of the receiving frame 41 , and a gear transmission system 42 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com