High-load-bearing full-sealed disk-type structure vibration isolation device

A fully-sealed, high-load-bearing technology, used in shock absorbers, building components, spring/shock absorber design features, etc. Ensure the effect of vertical deformation and elastic capacity, vertical bearing capacity increase, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

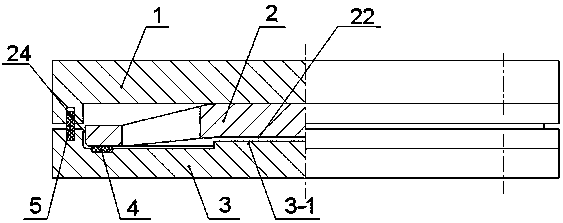

[0024] A high-load full-sealed disc structure vibration isolation device mainly includes a cover plate 1, a disc structure vibration isolator 2 and a bottom basin 3, such as figure 1 As shown, the cover plate 1 has a cover-type structure with a ring-shaped edge, and the bottom basin 3 is a disc-shaped structure with a ring-shaped edge. Clearance, during installation, when the disc structure vibration isolator 2 is placed in the bottom basin 3, then cover the top of the disc structure vibration isolator 2 with a cover plate 1, so that the disc structure vibration isolator 2 is surrounded by Between the cover plate 1 and the bottom basin 3. The entire vibration isolation device is used as a whole, and a superstructure for loading a load can be added above the cover plate 1, and the device is placed on the basic structure at the same time to realize lower support and upper load.

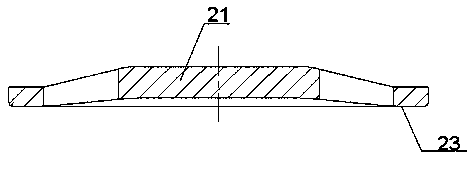

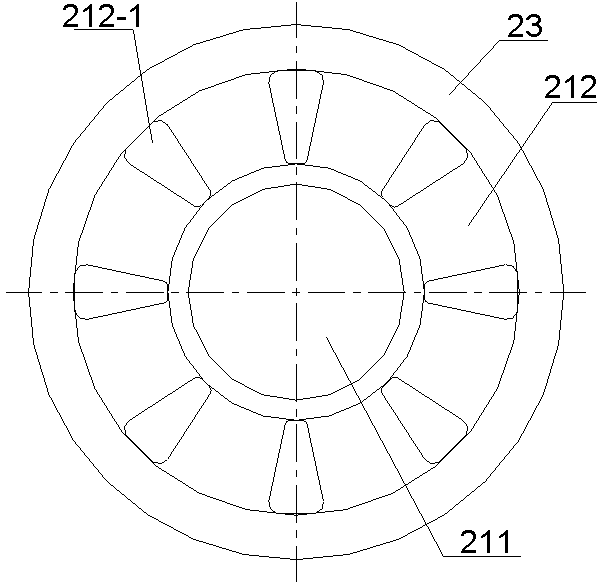

[0025] Such as figure 2 As shown, the disc structure vibration isolator 2 is a centrally symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com