Multi-shelf furnace for use at low temperature

A furnace, central shaft technology, applied in the field of industrial thermal reactors, can solve problems such as excessive thermal inertia, consumption of fossil fuels, and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

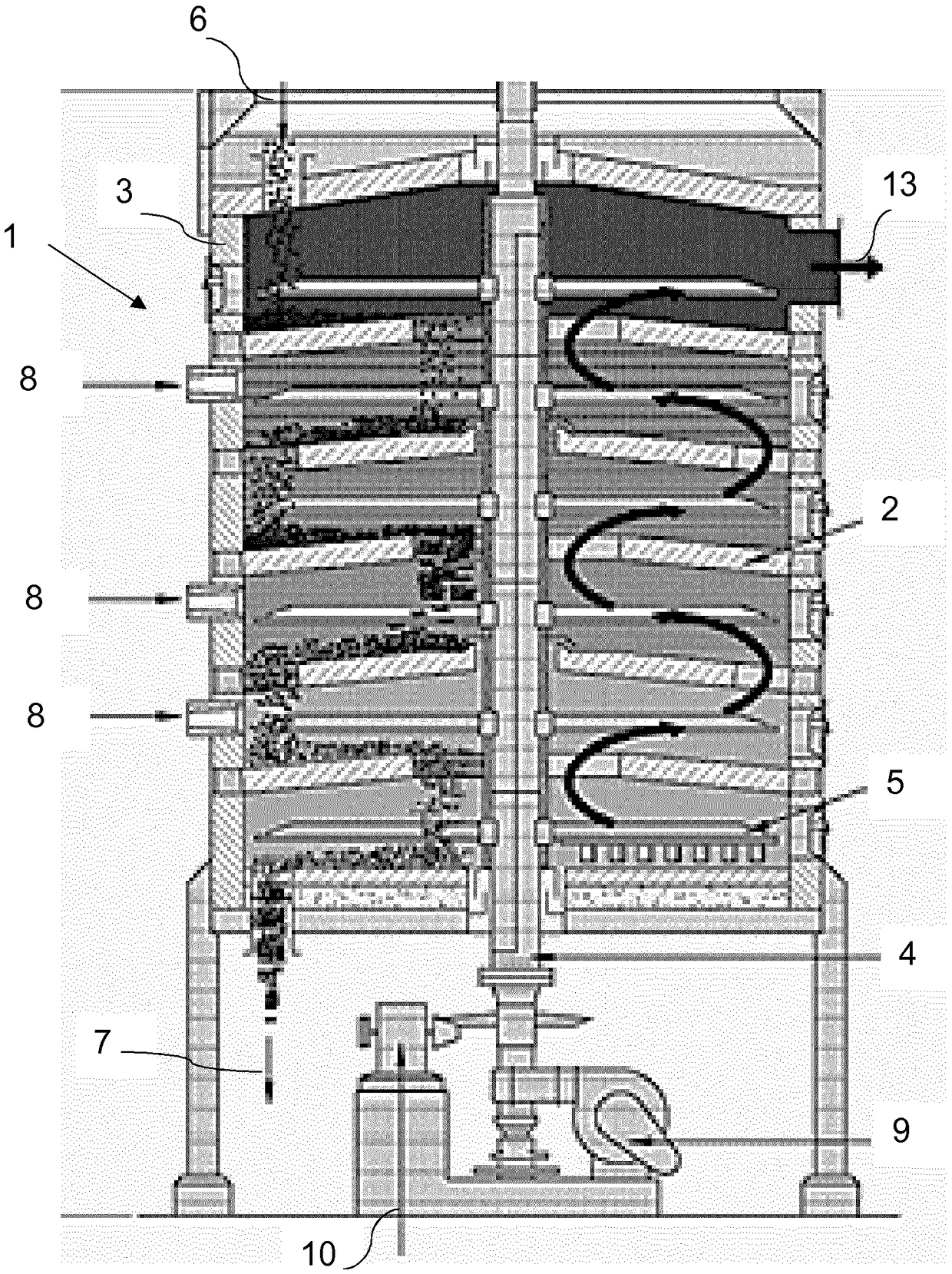

[0053] The present invention proposes a multi-hearth furnace called "MHF 100 / 0" (stands for 100% Metal, 0% Injected Fuel), which is particularly suitable for low-temperature heat treatment, in particular torrefaction and / or drying of waste or biomass, Mainly through:

[0054] - Replacement of components of stirring machinery by mechanically welded and non-cooled assemblies;

[0055] - replace inner refractory with standard outer insulation;

[0056] - replacing the hearth in the form of a "Chinese hat" with a flat metal hearth;

[0057] - Replacement of fossil fuel burners with thermal oil radiant tubes fixed under the hearth;

[0058] - Substitution of fossil fuels with vital energy sources, e.g. through simple flue gas / thermal oil exchangers.

[0059] Advantageously, most of the metal components used to make such furnaces are standard stainless steel components that are readily commercially available.

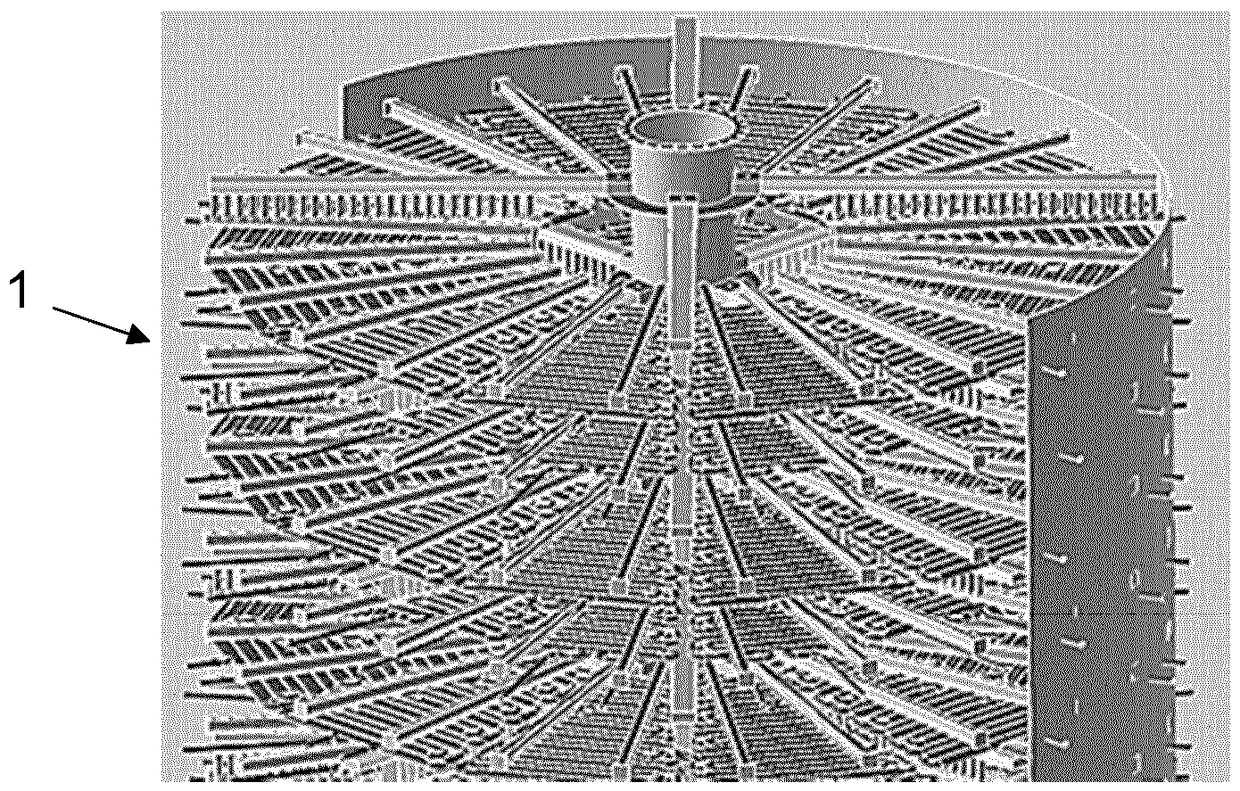

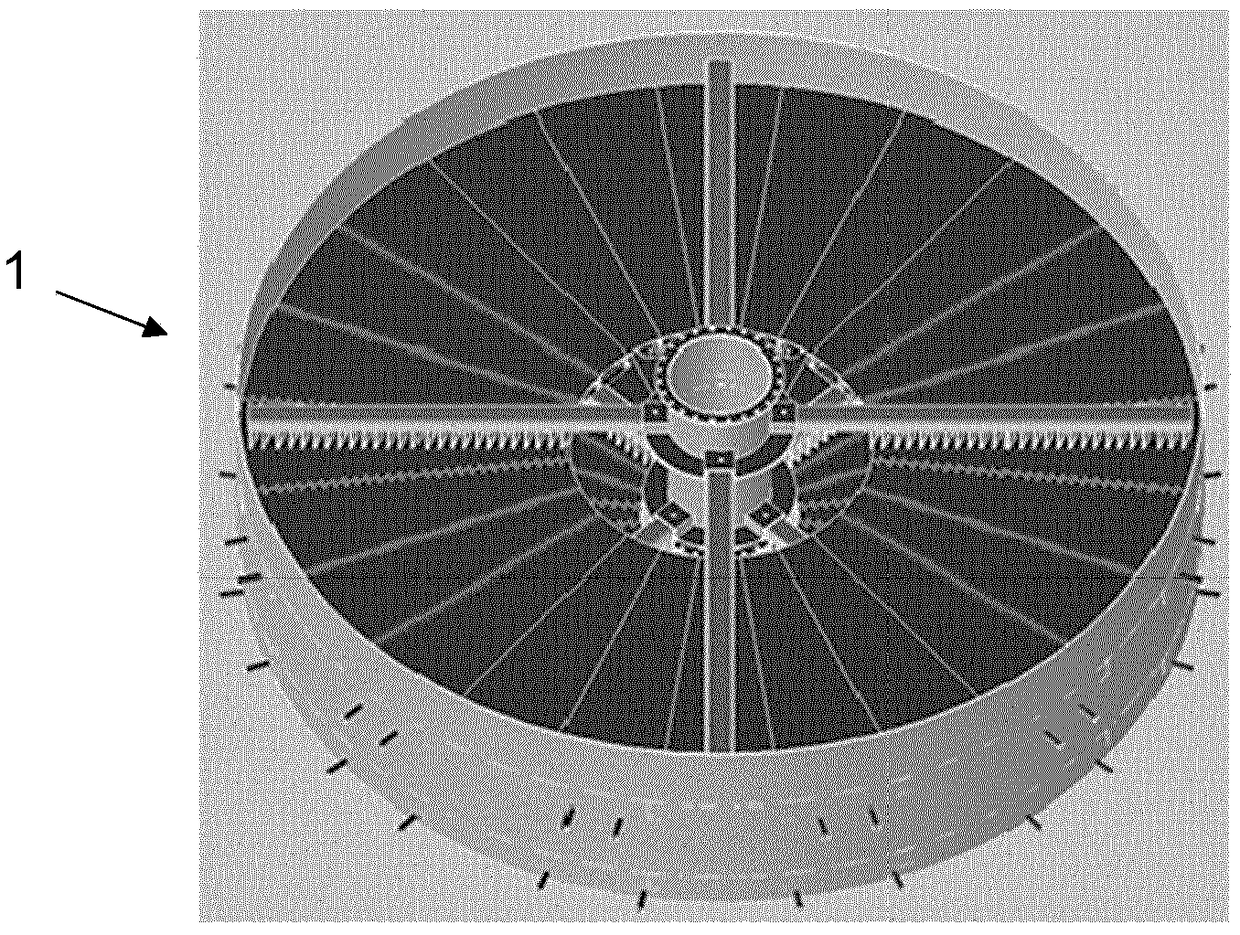

[0060] Figure 2A with 2B An overview of one example of such a fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com