Multi-shelf Furnaces for Low Temperatures

A furnace and stirring arm technology, used in the field of industrial thermal reactors, can solve problems such as expensive, unsuitable, and poor size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

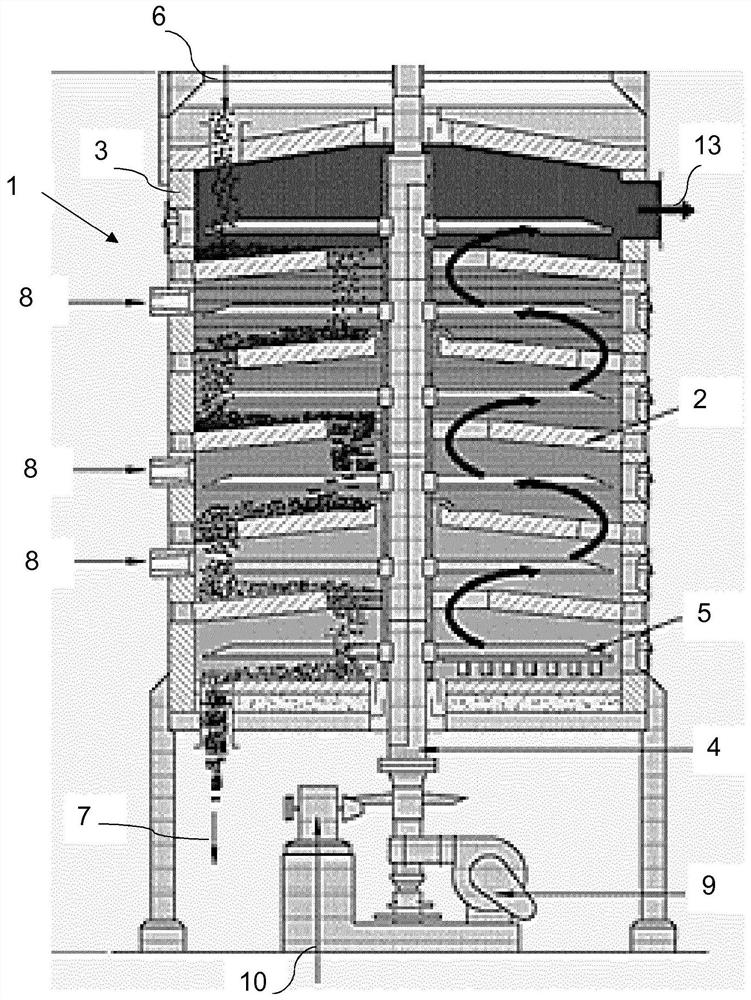

[0051] The present invention proposes a multi-hearth furnace called "MHF 100 / 0" (representing 100% metal, 0% fuel injection), which is particularly suitable for low-temperature heat treatment, especially torrefaction and / or drying of waste or biomass, Mainly through:

[0052] -Replace the components of the mixing machine with mechanical welding and non-cooling assemblies;

[0053] -Use standard outer insulating materials instead of inner refractory materials;

[0054] -Replace the hearth in the form of "Chinese hat" with a flat metal hearth;

[0055] -Replace the fossil fuel burner with a hot oil radiant tube fixed under the furnace;

[0056] -Replace fossil fuels with important energy sources, for example through simple flue gas / hot oil exchangers.

[0057] Advantageously, most of the metal components used to make such furnaces are standard stainless steel components that are easily commercially available.

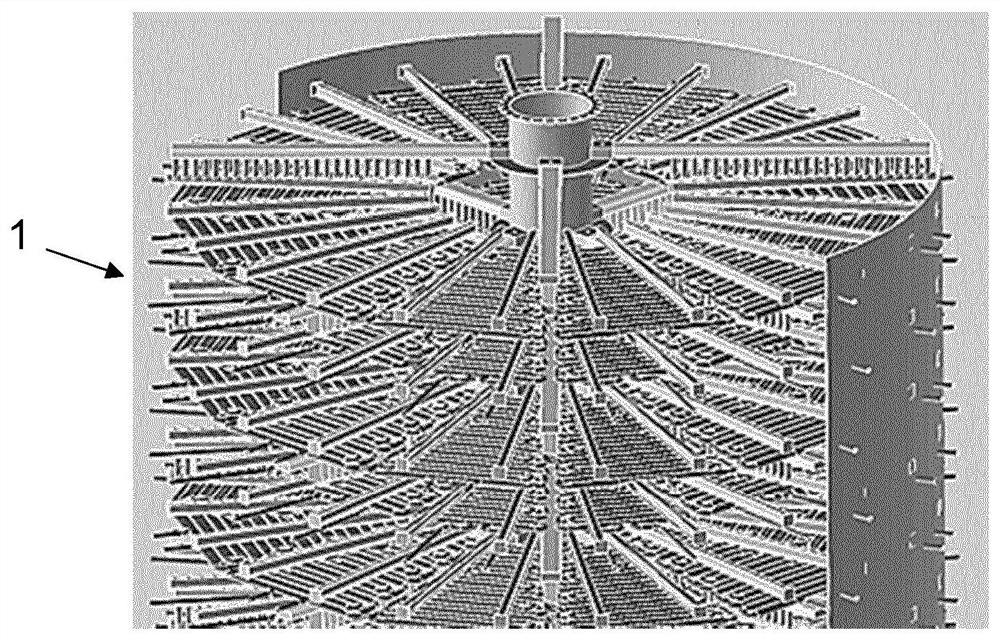

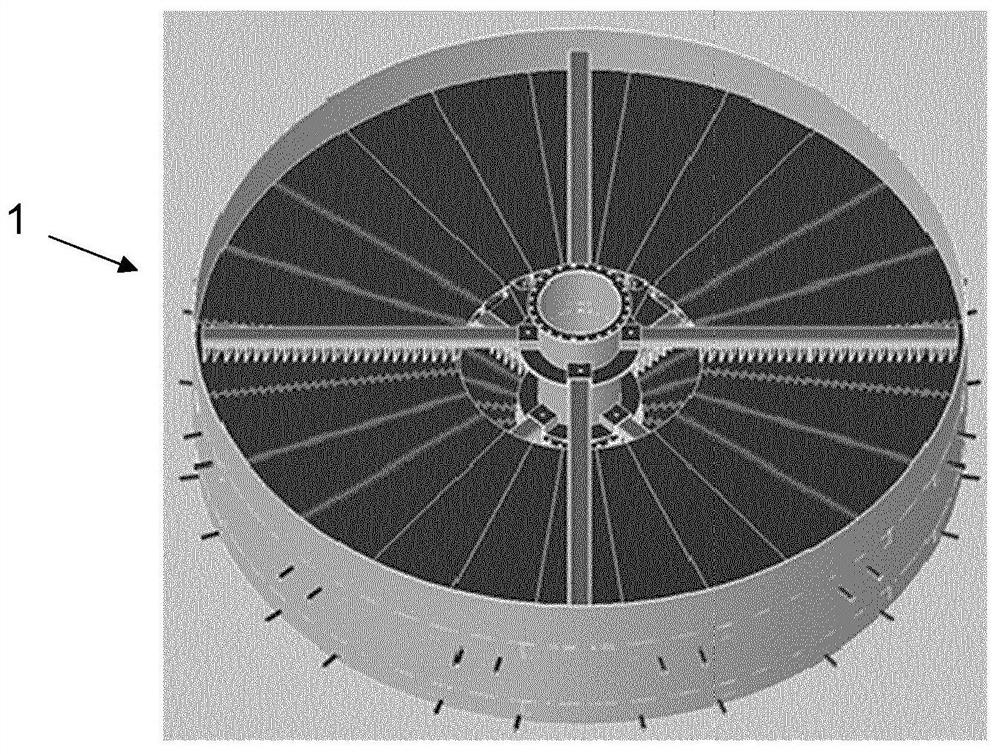

[0058] Figure 2A with 2B A schematic diagram of an example of such a furnace i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com