Acoustic absorber, acoustic wall and method for design and production

A technology of sound absorption and absorber, which is applied in the direction of sound-emitting devices, instruments, sensors, etc., can solve the problem of difficult to predict the cost of active sound-absorbing walls, and achieve the effect of easy industrial manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0122] ●Single absorber

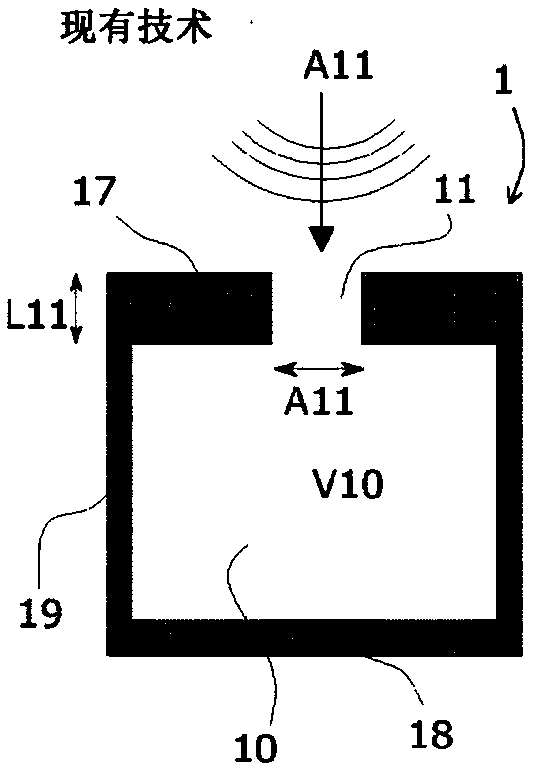

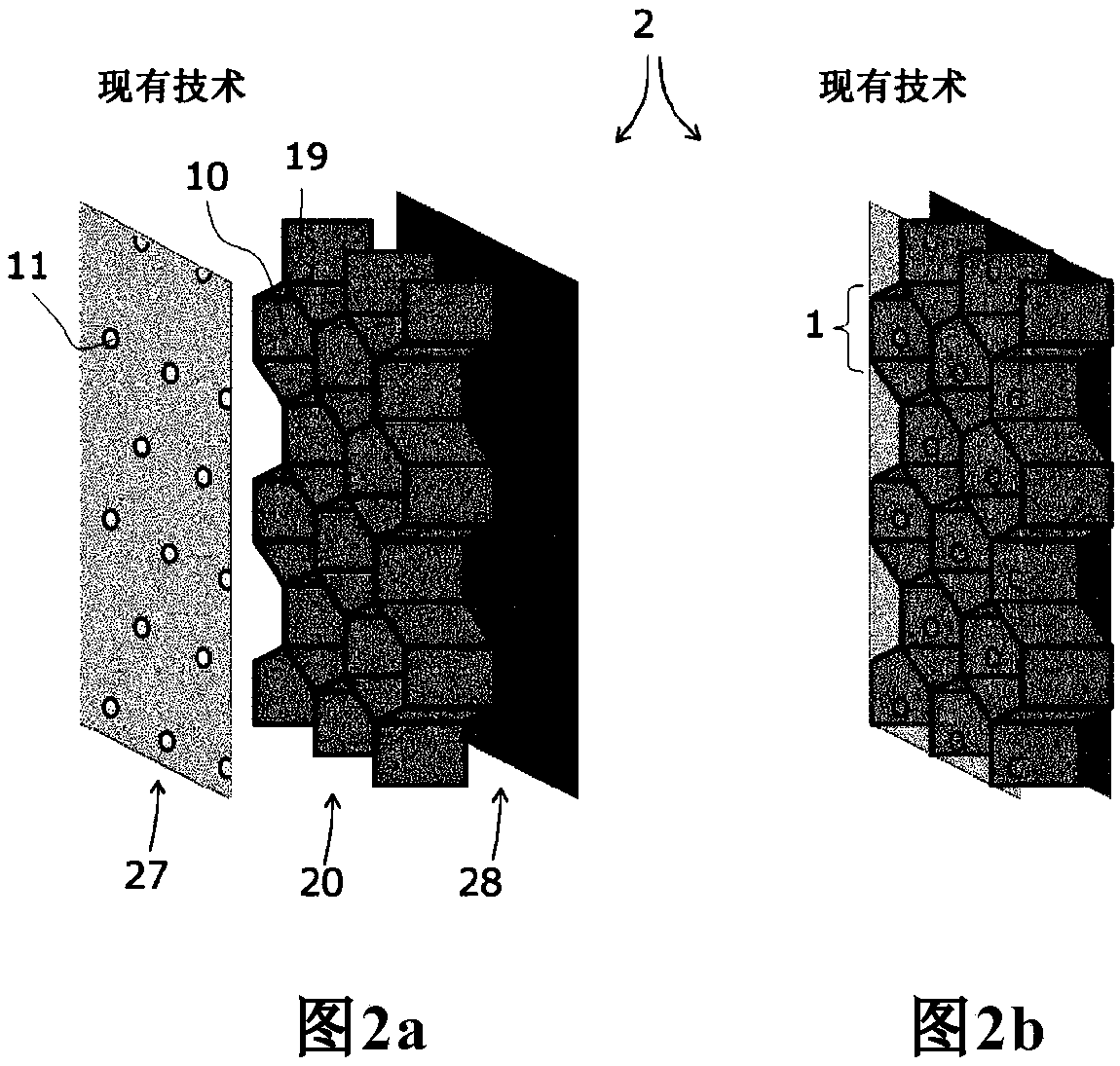

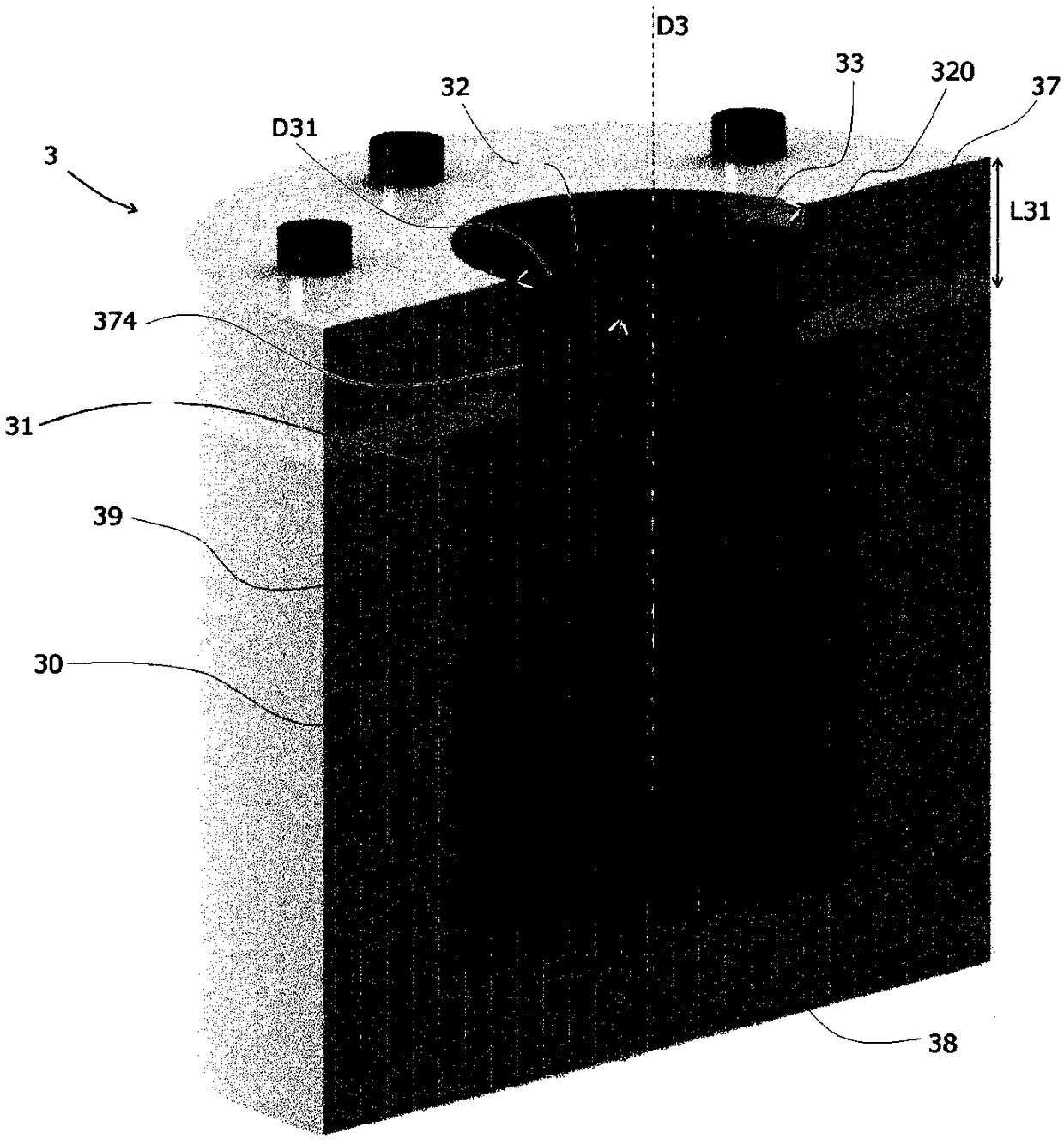

[0123] Figure 1 to Figure 7 A first example of an embodiment of the present invention is shown. For other examples, only their differences from the first embodiment will be described.

[0124] In a first example of this embodiment, an absorber 3 was fabricated and tested in the context of a study originally aimed at implementing an active noise reduction system with loudspeakers.

[0125] The absorber 3 has a cylindrical shape defining an inner cavity 30 . This cavity 30 is surrounded by a cylindrical wall 39 which is completely closed by a rear flat wall 38 and partly by a front wall 37 . The front wall 37 is pierced with a central hole opening towards the cylinder of the cavity 30 in the axial direction D3. The hole has a cylindrical shape passing through the thickness of the front wall 37 , forming a neck 31 of length L31 and having a cross section of A31 .

[0126] In the example described here, the wafer used is formed from a sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com