Beef jerky and production process thereof

A production process and technology of beef jerky, which is applied in the field of food processing, can solve problems such as difficulty in contact with hot air, uneven heating, uneven drying of beef jerky, etc., and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further detailed explanation through specific implementation mode below:

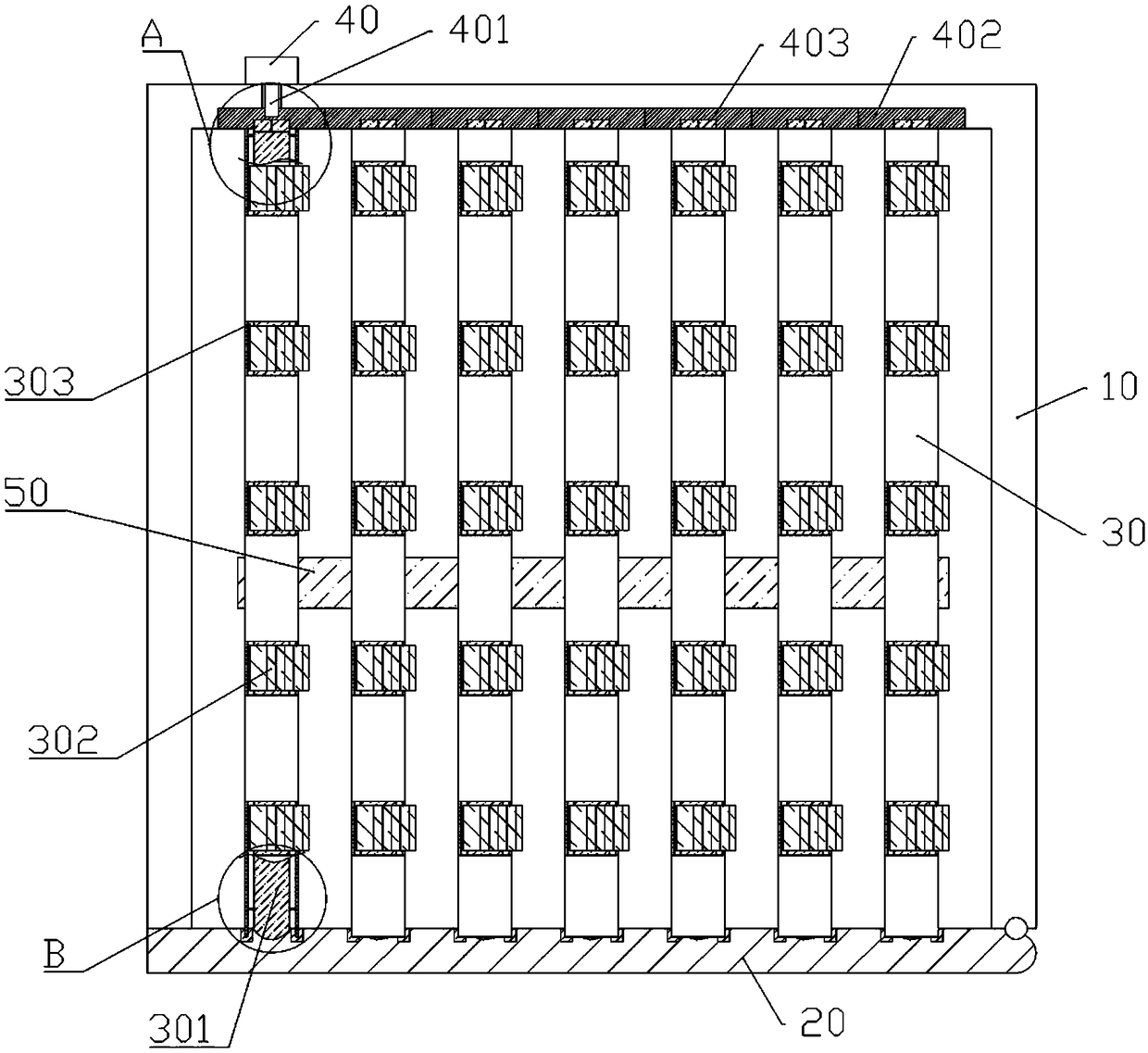

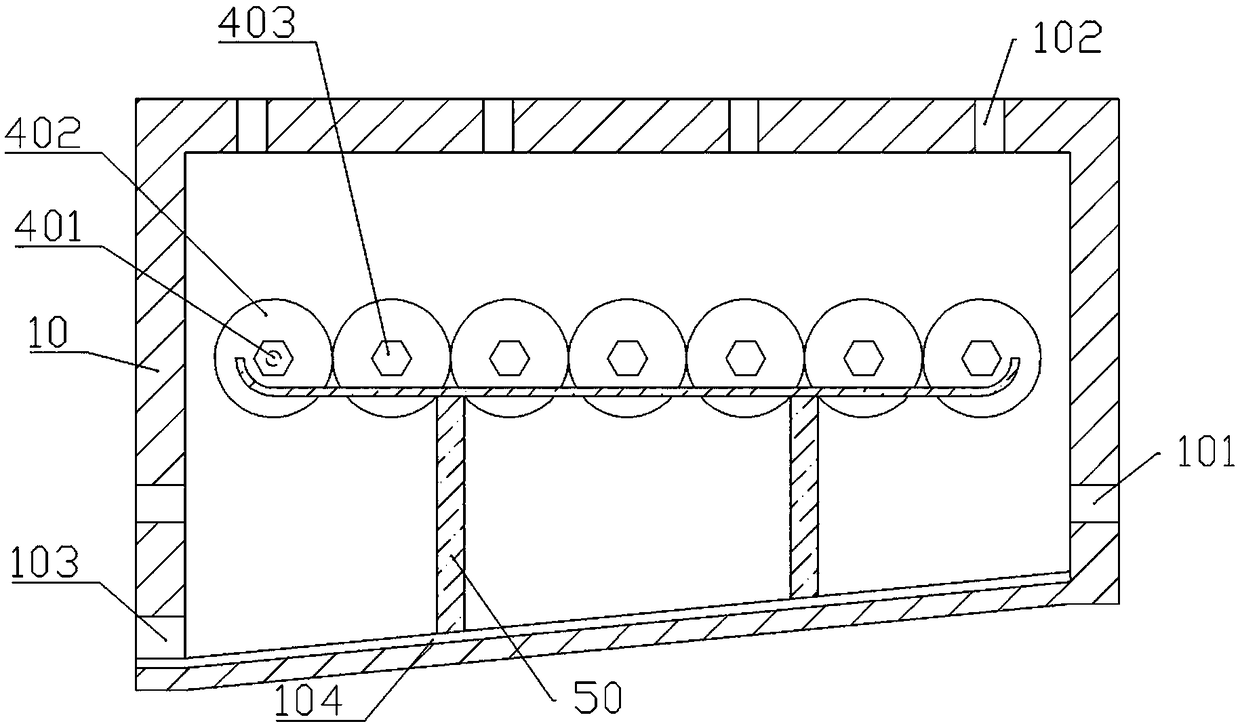

[0026] The reference signs in the drawings of the description include: box body 10, air inlet 101, air outlet 102, material outlet 103, water guide groove 104, sealing door 20, gasket 201, arc surface 202, sleeve 30, rotating shaft 301, supporting gear 302 , through hole 303 , support frame 204 , motor 40 , transmission shaft 401 , driving gear 402 , limit hole 403 , and cage 50 .

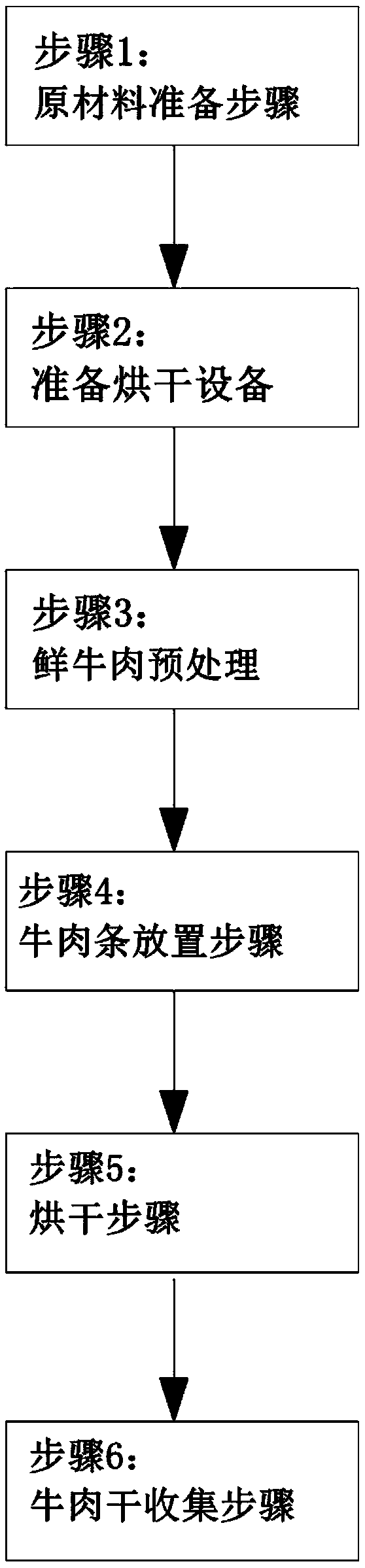

[0027] The implementation process of a kind of beef jerky and its production technology in the embodiment is basically as attached figure 1 As shown, the specific operation steps are as follows:

[0028] Step 1: Prepare the raw materials. The quality of each component in the raw materials is as follows: 12kg of fresh beef, 0.6kg of white sugar, 0.5kg of edible salt, 0.9kg of rice wine, 0.7kg of spices and 0.3kg of pepper.

[0029] Step 2: Prepare a basic as attached figure 2 , attached image 3 , attached Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com