Shoe washing machine set and annular shoe washing method thereof

A unit and circular technology, which is applied to the cleaning of boots and shoes, cleaning equipment, household appliances, etc., to reduce labor costs, improve shoe washing efficiency, and reduce labor input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Further details will be given below in conjunction with the embodiments shown in the accompanying drawings.

[0031] The present invention proposes a ring-shaped shoe washing method, comprising the following steps:

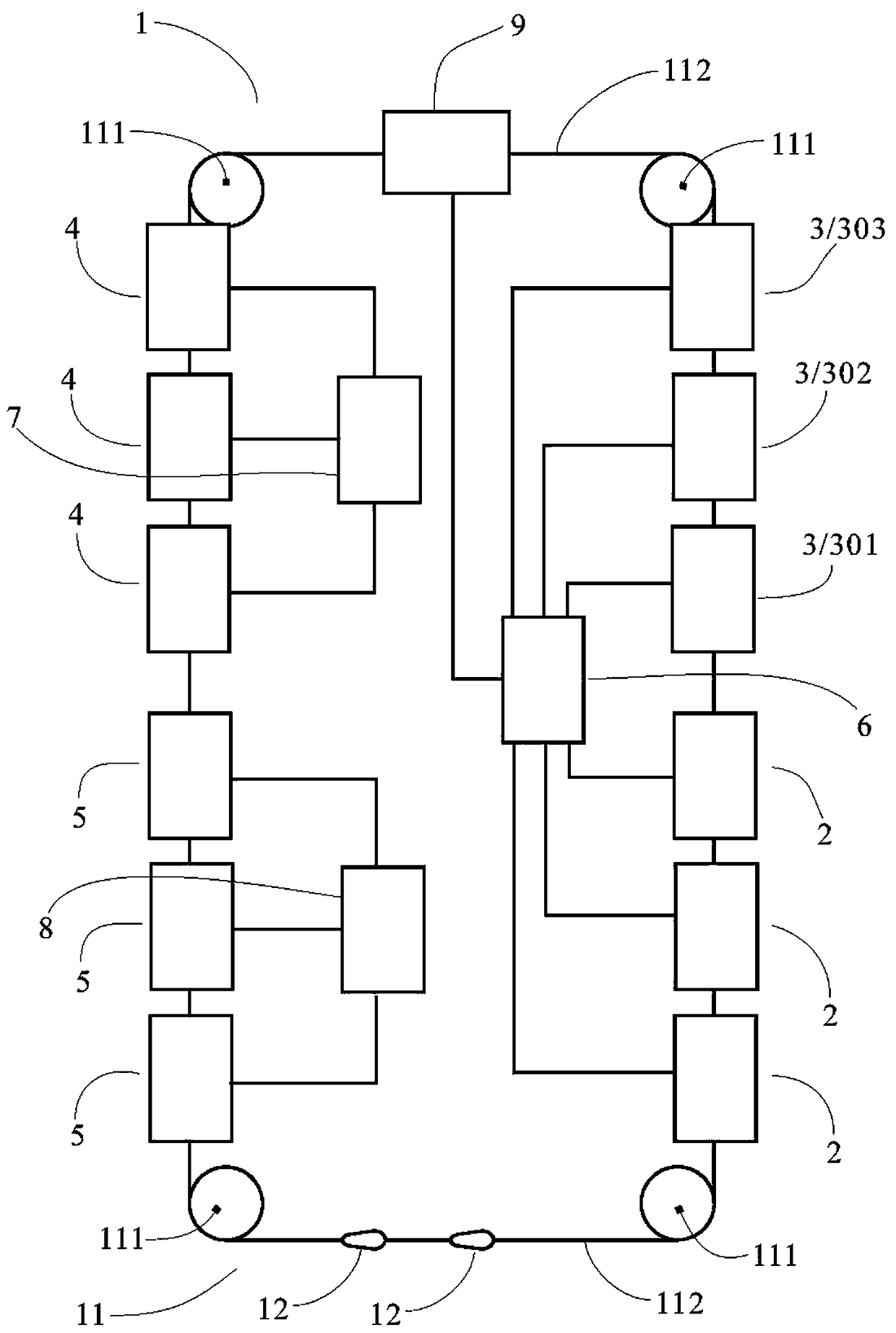

[0032] A. If figure 1 As shown, the transmission assembly 11 that can move along the circular path connected by the first place is set, and at least one shoe support 12 for installing the shoes to be cleaned is installed on the transmission assembly 11, so that the shoe support 12 can be displaced along the circular path;

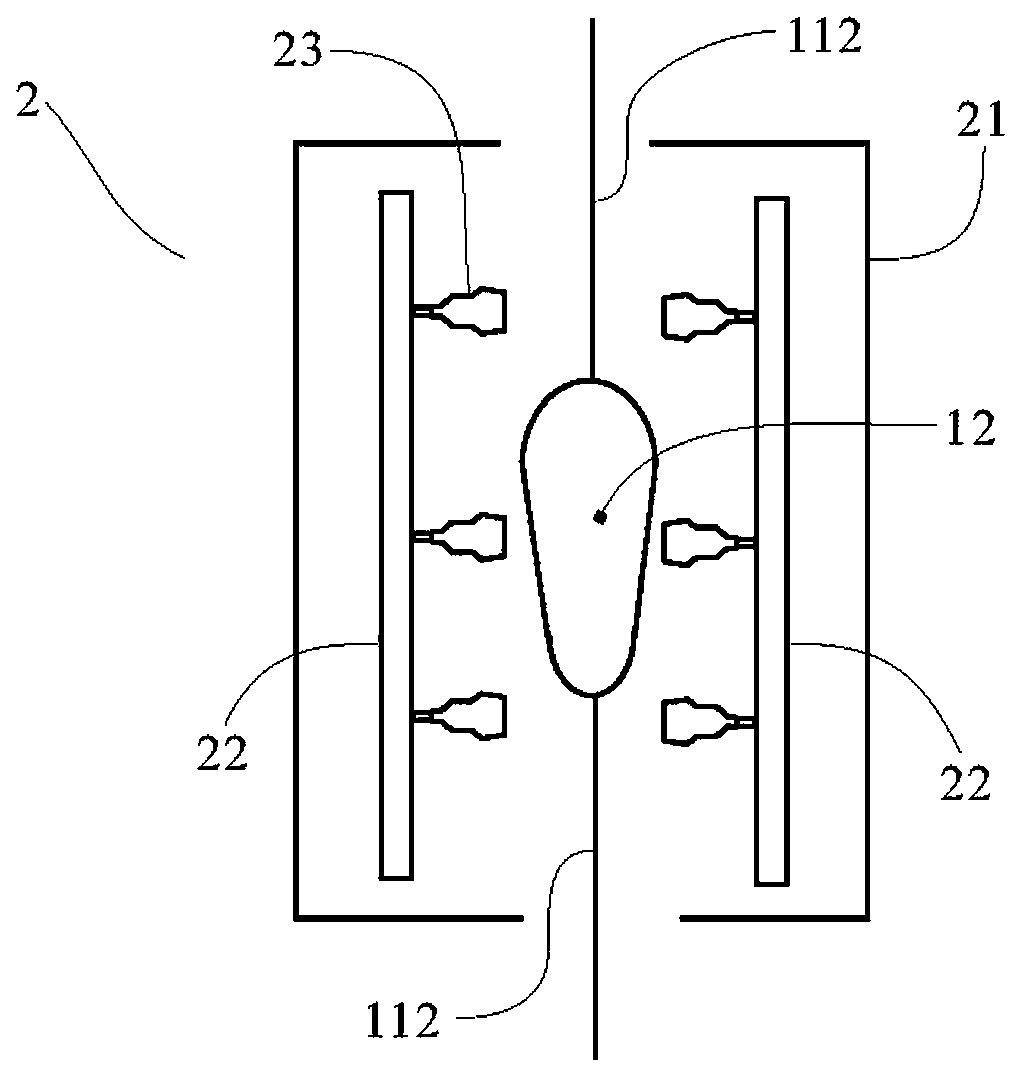

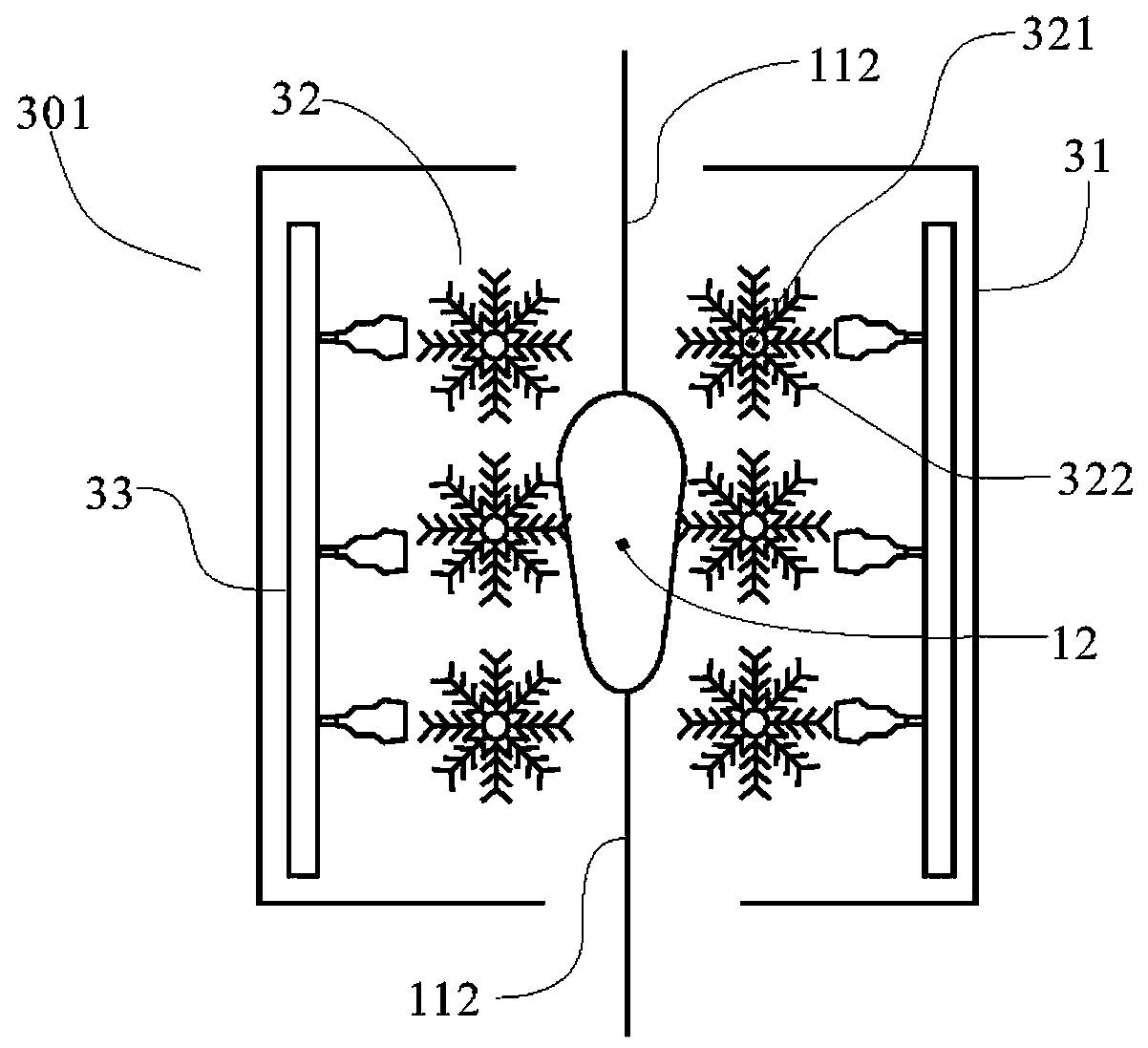

[0033] B. At least one spraying station device 2, at least one brushing station device 3, at least one rinsing station device 4 and at least one wind shear dehydration device 5 are arranged sequentially on the circular path of the conveying assembly 11; cleaning liquid water supply is also provided Device 6, clean water supply device 7 and high-pressure blower device 8; during the displacement process of shoe support 12 along the circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com