Laboratory waste gas treatment system and treatment method thereof

A waste gas treatment and laboratory technology, applied in the field of air purification, can solve problems such as inability to deal with laboratory waste gas, and achieve high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

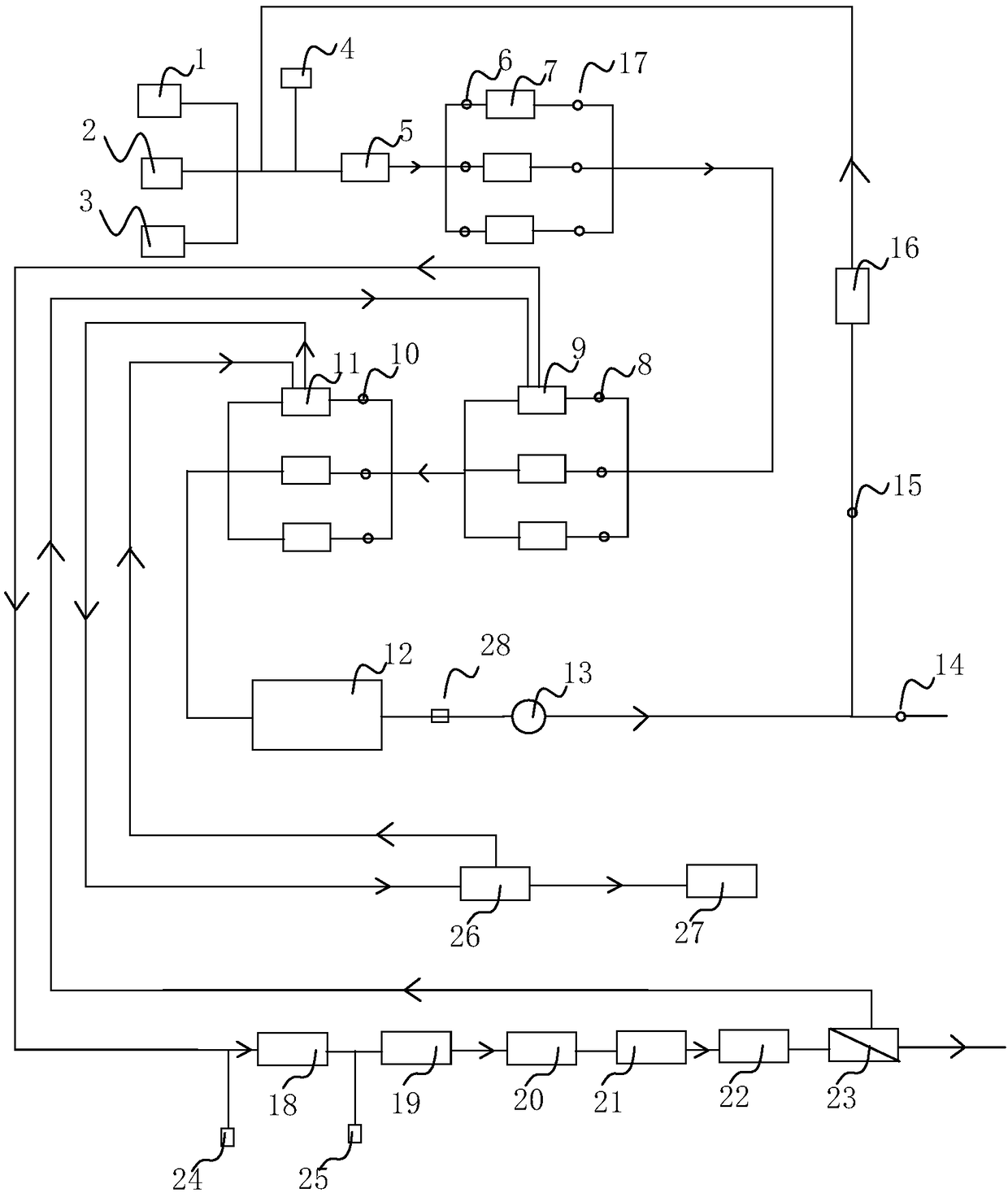

[0022] This embodiment is a treatment plan for a certain laboratory waste gas, refer to figure 1 ,details as follows.

[0023] The first gas collection port 1 is a gas collection hood arranged on the main operating table of the laboratory. Since the area where it is located is generally the source of laboratory exhaust gas, a fan for enhanced drafting can be installed on the gas collection hood according to the actual situation; the second episode Air port 2 is a gas collection hood set on the top of the laboratory, which is used to collect the exhaust gas diffused throughout the laboratory, and generally no additional fan is installed; the air pressure balance port 3 is set outside the laboratory and connected to the first gas collection port 1 and the second gas collection port 2 are connected in parallel to the main pipeline to balance the pressure in the gas flow pipeline of the treatment system.

[0024] The main pipeline is provided with a pipeline mixer 5, and the ozon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap