Paint spraying device for production surface of chemical engineering material

A technology for chemical and paint spraying guns, which is applied to the device for coating liquid on the surface, the spraying device, the liquid spraying device, etc., can solve the problems of contamination with dust, waste, paint can not be dried in time, affecting the overall effect of chemical materials, etc. The effect of spray paint drying quickly and preventing dust contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

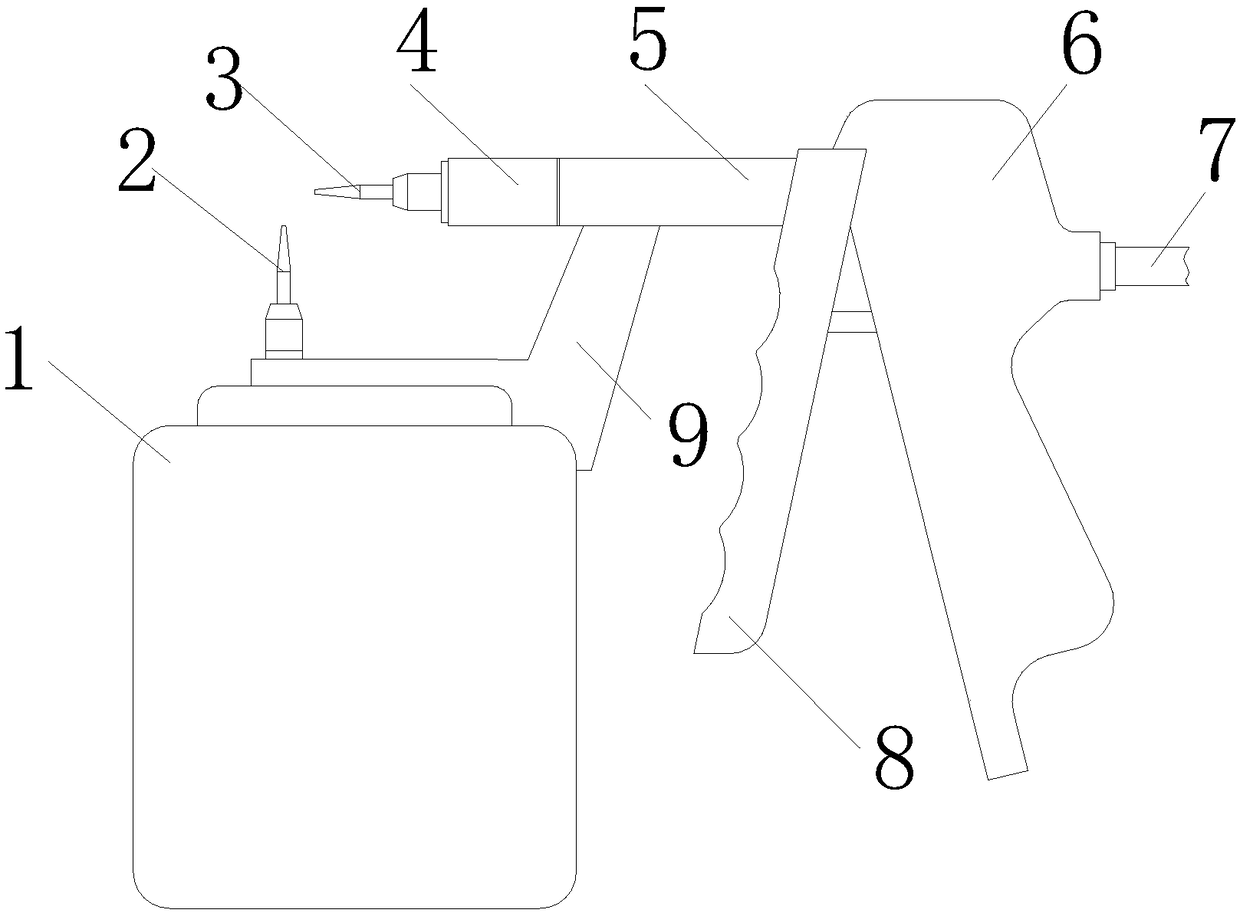

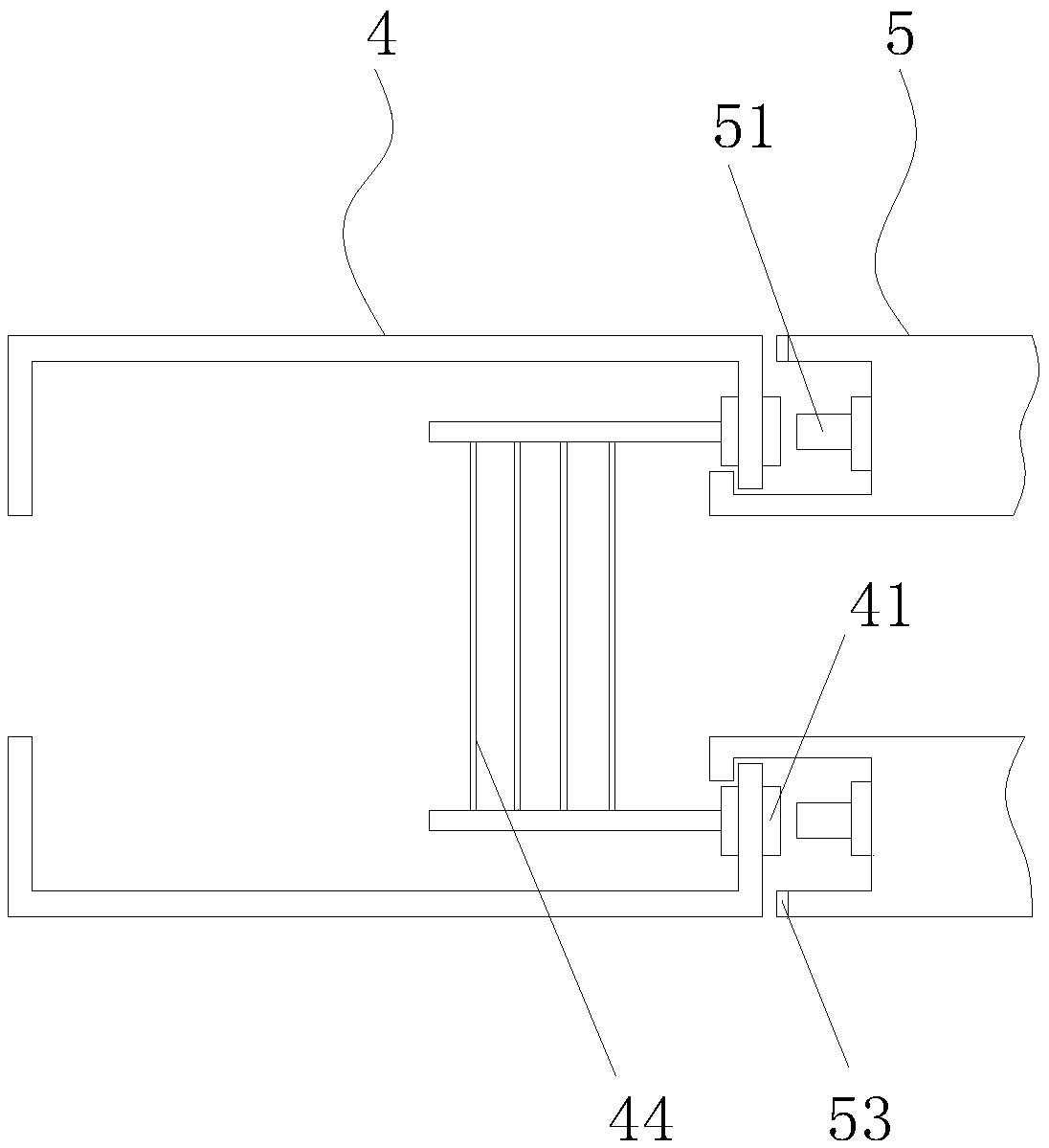

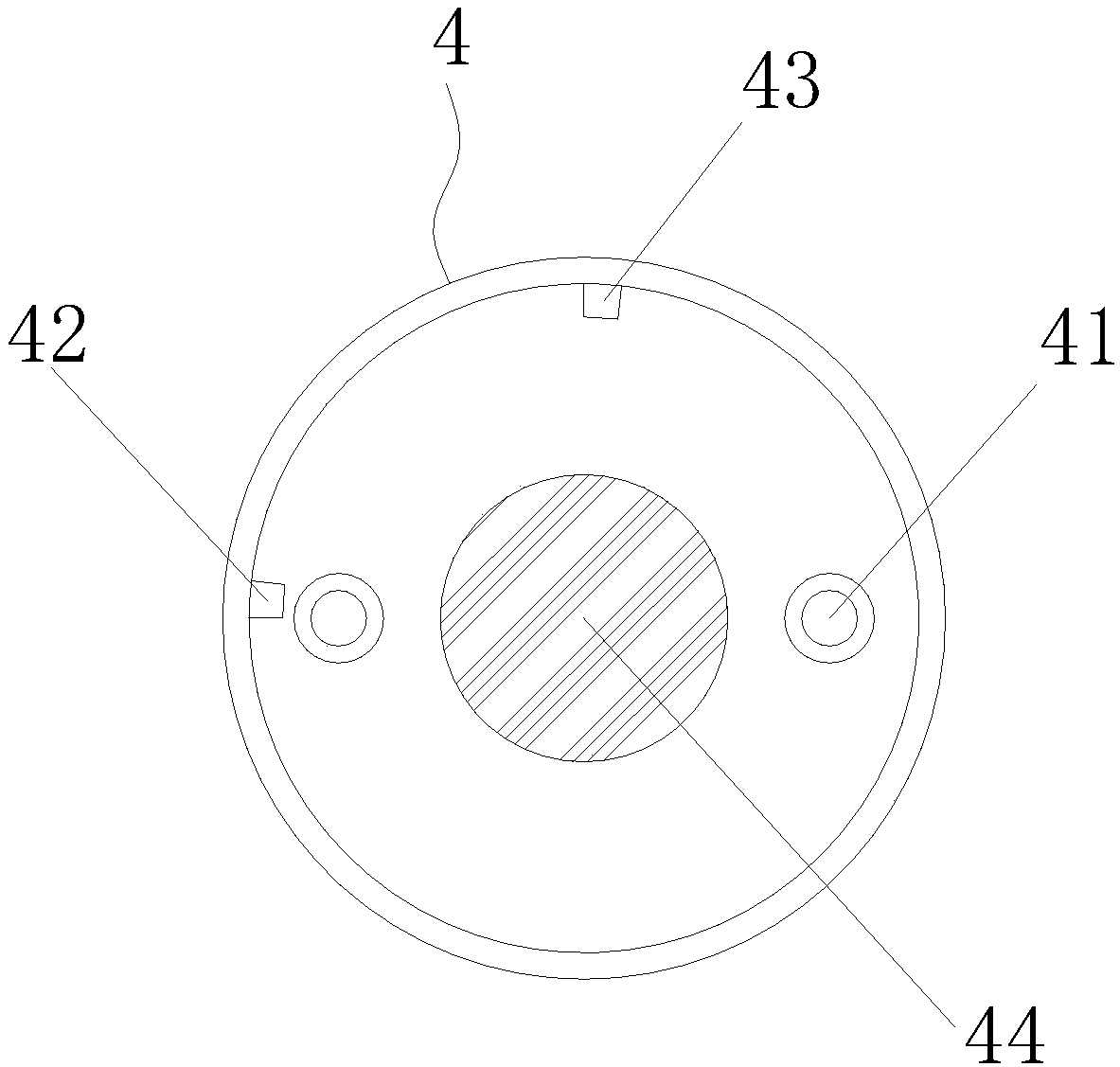

[0020] see Figure 1-4 , the present invention provides the following technical solutions: a surface painting device for producing chemical materials, comprising a paint bucket 1, a paint spray gun body 6, a handle 8 is provided on one side of the paint spray gun body 6, and the other side of the paint spray gun body 6 away from the handle 8 An air pressure input terminal 7 is provided, and a spray barrel 5 is integrally formed on the side close to the handle 8 at the upper end of the paint spray gun body 6, and the other end of the spray barrel 5 away from the paint spray gun body 6 is rotatably connected with a heater device 4, and the spray barrel 5 is connected to the heater The end connected to the device 4 is provided with two metal caps 51, and the inner wall of the end of the spray tube 5 connected to the heater device 4 is provided with a limit strip 52, and the other end of the heater device 4 away from the spray tube 5 is provided with a second nozzle. 3;

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com