An aircraft electric heating deicing control circuit

A control circuit and electric heating technology, which is applied to deicing devices, aircraft parts, transportation and packaging, etc., can solve the problems of unsatisfactory anti-icing effect, low safety in use, and few anti-icing control circuits, so as to meet the requirements of deicing. Effects of functional and safety requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

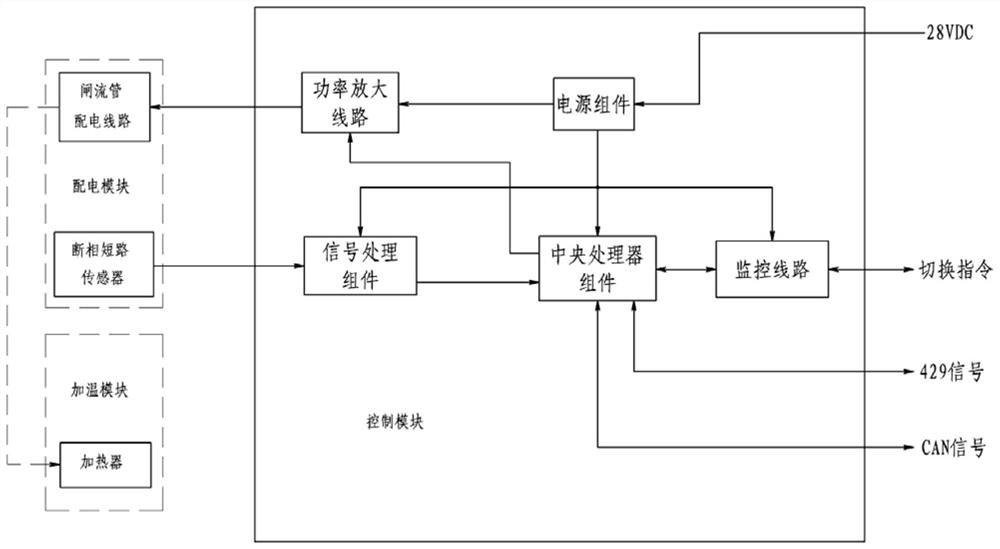

[0011] The present invention will be described in further detail below. refer to figure 1 .

[0012] 1) The power supply component receives the 28VDC of the aircraft and converts it to supply power to the power amplifier circuit and the central processing unit;

[0013] 2) The central processing unit receives the signal of the signal processing unit, the signal of the monitoring circuit and the bus signal, and provides the control signal to the power amplification circuit and the switching signal to the monitoring circuit;

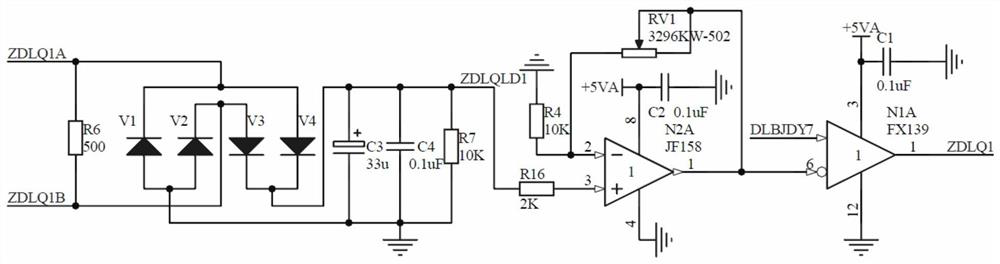

[0014] 3) The central processing unit receives the signal from the host computer through the 429 bus, and judges whether the deicing is satisfied. When the heating module starts to perform the deicing and heating function, after the phase failure and short-circuit fault occur, the power distribution module phase-opening and short-circuit detection sensor can send fault signal to the signal processing component ( figure 2 shown) for processing, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com