Device for trimming clay model used for industrial automobile design and trimming method of device for trimming clay model used for industrial automobile design

A technology of sludge model and automobile industry, applied in manufacturing tools, ceramic molding machines, etc., can solve problems such as blockage, difficulty in collecting collection boxes, affecting collection effect, etc., to improve collection effect, space utilization rate, and collection volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

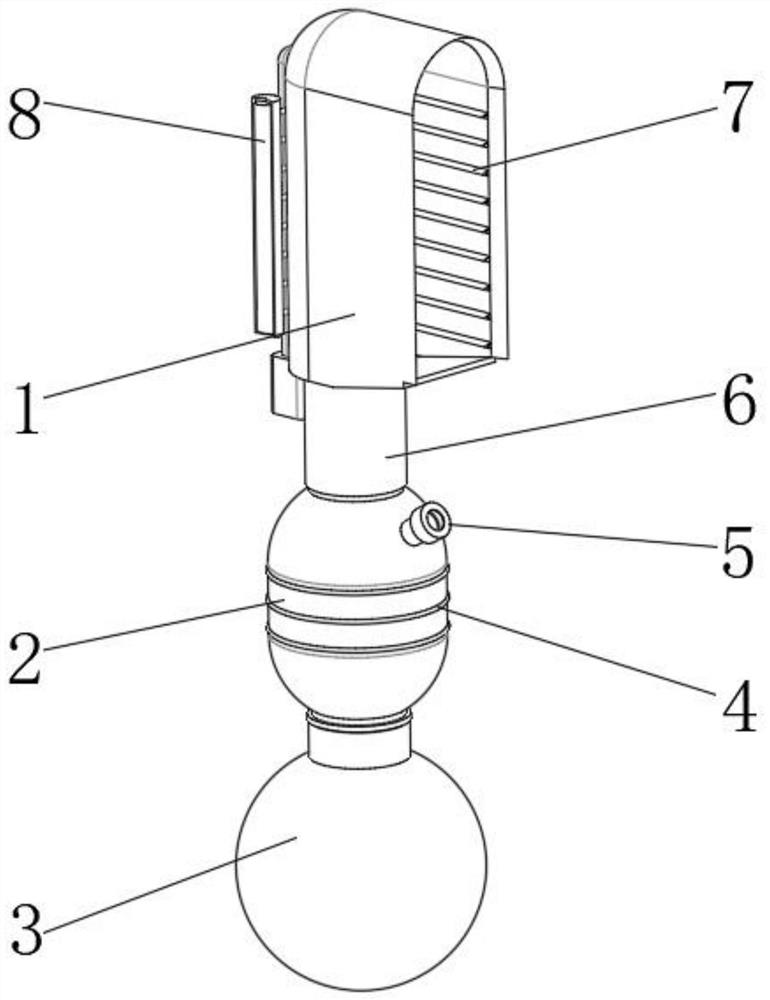

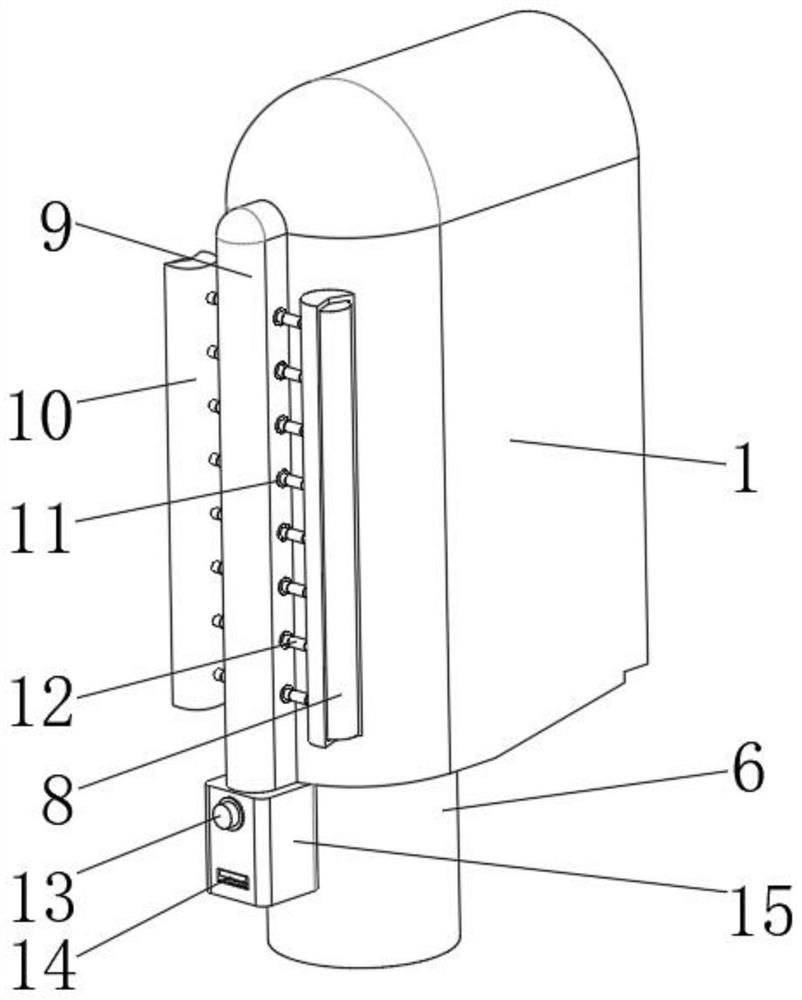

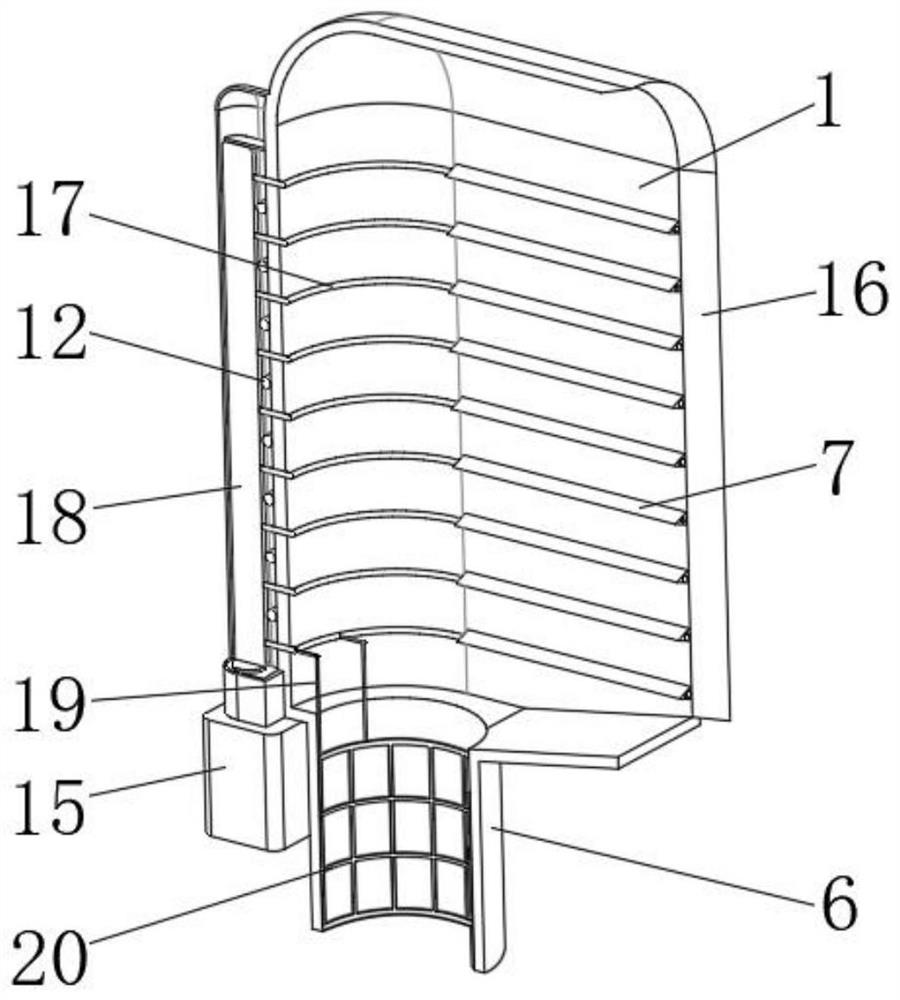

[0039] A kind of oil sludge model trimming device for automotive industry design, such as Figure 1-5As shown, it includes a scraper cover 1, the outer wall of one side of the scraper cover 1 is provided with a scraper cornice 16 for trimming, the outer wall of the bottom of the scraper cover 1 is integrally provided with a connecting pipe 6, and the inner wall of the bottom of the scraper cover 1 is connected to The center of the circle at the top of the pipe 6 is sunken, and the outer wall of the bottom of the connecting pipe 6 is fixed with a connecting frame 22 by screws. The same airbag 2 is bonded, and the airbag 2 is set on the outside of the connecting frame 22. The outer wall of one side of the airbag 2 is provided with a one-way pressure relief valve 5, and the bottom side wall of the fixed seat 23 is threadedly connected with a collection chamber 3; By setting up structures such as the scraper cover 1 and the collection chamber 3, the scraper eaves 16 can be used to...

Embodiment 2

[0049] A method for trimming a sludge model trimming device for automobile industry design, comprising the steps of:

[0050] S1: Operate the control button 13 to control the working state of the electric heating rod 18 as required;

[0051] S2: Hold the airbag 2 and the connecting pipe 6 to control the scraping eaves 16 to trim the outer surface of the model;

[0052] S3: During trimming, adjust the position of the flexible roller 8 by sliding the connecting rod 12 in the rubber sleeve 11, and perform simple compaction work on the trimmed model through the flexible roller 8;

[0053] S4: When trimming, repeatedly squeeze the air bag 2 to prevent clogging and assist the side material to enter the collection chamber 3;

[0054] S5: After the trimming is completed, the collection chamber 3 is removed from the fixing seat 23 and recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com