Spheroidizing device and spheroidizing method of spheroidal graphite cast iron

A ductile iron and spheroidization technology, applied in the field of ductile iron smelting, can solve the problems of less input of spheroidizing inoculants, reduced operator labor, and high equipment input costs, achieve favorable spheroidization absorption effect, and avoid spheroidization. Uniform and avoid insufficient spheroidization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

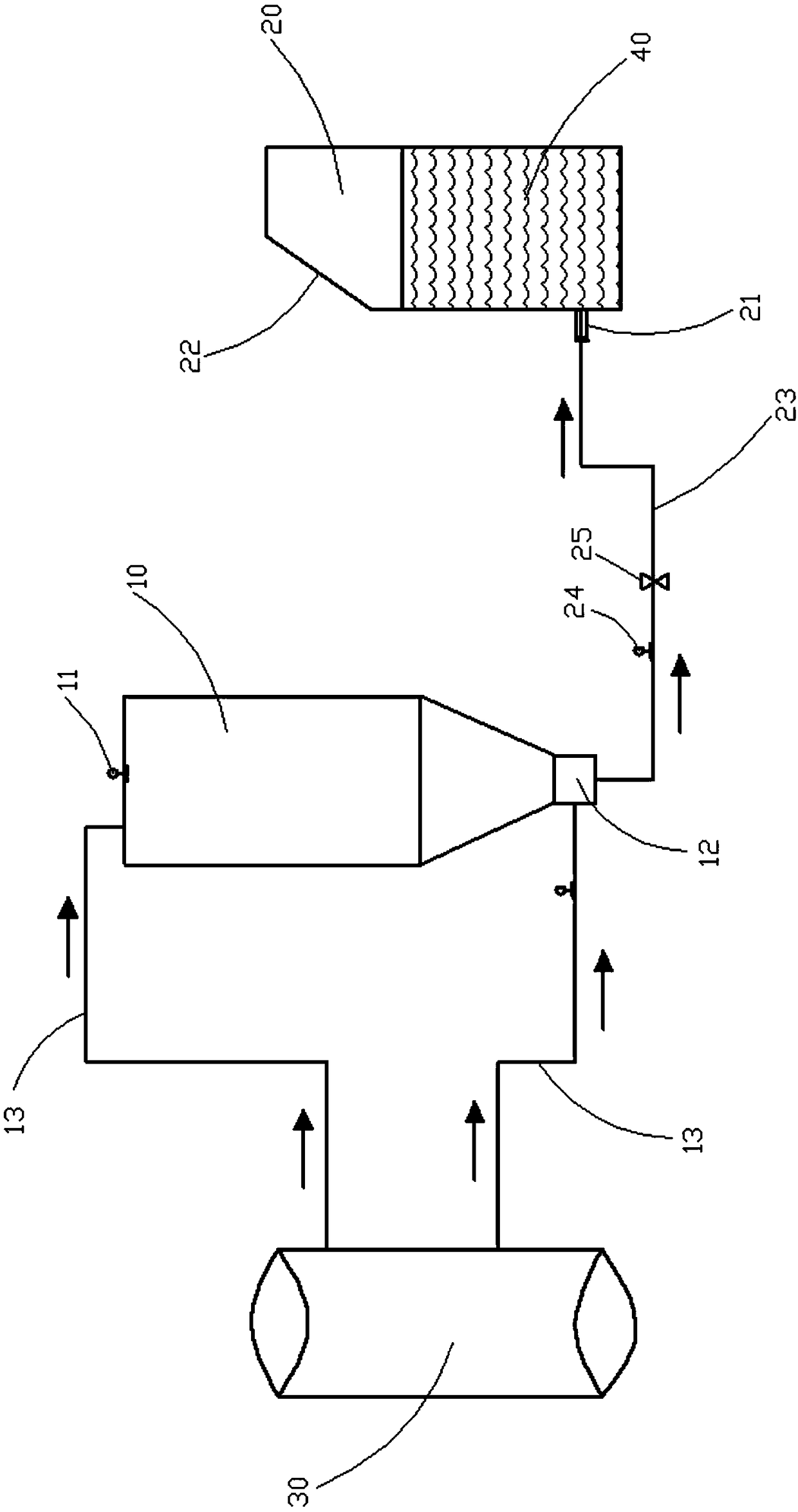

[0021] In order to illustrate the technical solution of the present invention more clearly, it will be described in detail according to the accompanying drawings. Obviously, the accompanying drawings in the following description are typical implementations of the present invention. For those of ordinary skill in the art, without paying Under the premise of creative work, other implementation modes can also be obtained according to these drawings.

[0022] Such as figure 1 The shown nodular cast iron spheroidizing device comprises a storage tank 10, a ladle 20 and a nitrogen source 30, wherein the upper part of the storage tank 10 is provided with a pressure monitoring device 11, and the lower part is provided with a feeder 12, and the feeder 12 consists of A blower and a pneumatic solenoid valve are formed, and the storage tank 10 is connected to a nitrogen source 30 through a connecting hose 13, wherein the connecting hose 13 provided on the upper part of the storage tank 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com