Hot metal spheroidizing treatment method

A technology for spheroidizing treatment and molten iron, applied in the field of chemical equipment, can solve the problems of reduced magnesium absorption rate, uneven coverage, uneven spheroidization, etc., and achieve the effect of improving absorption rate, increasing spheroidizing rate, and good spheroidizing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

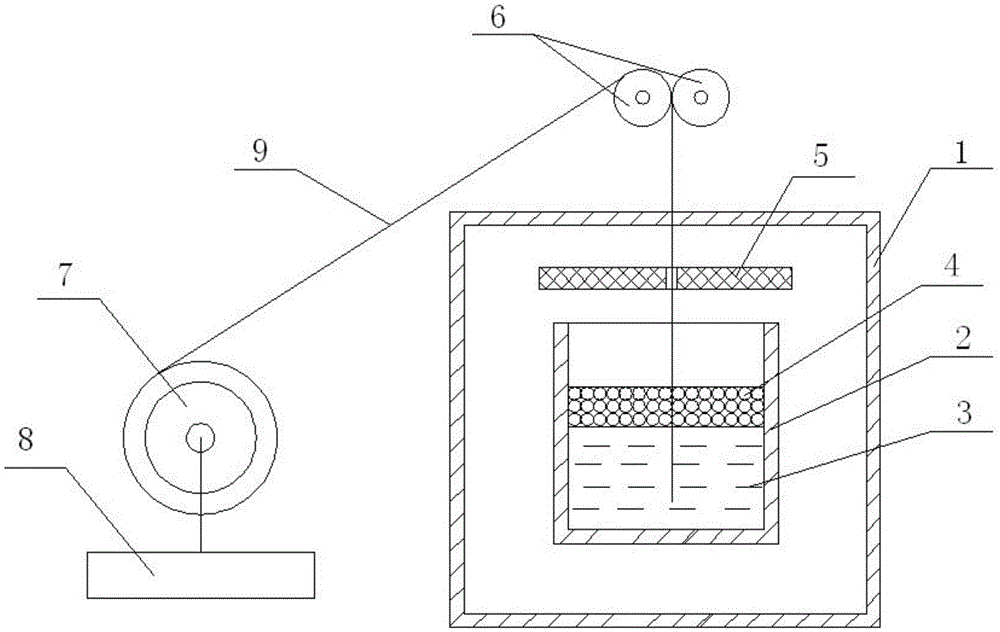

Method used

Image

Examples

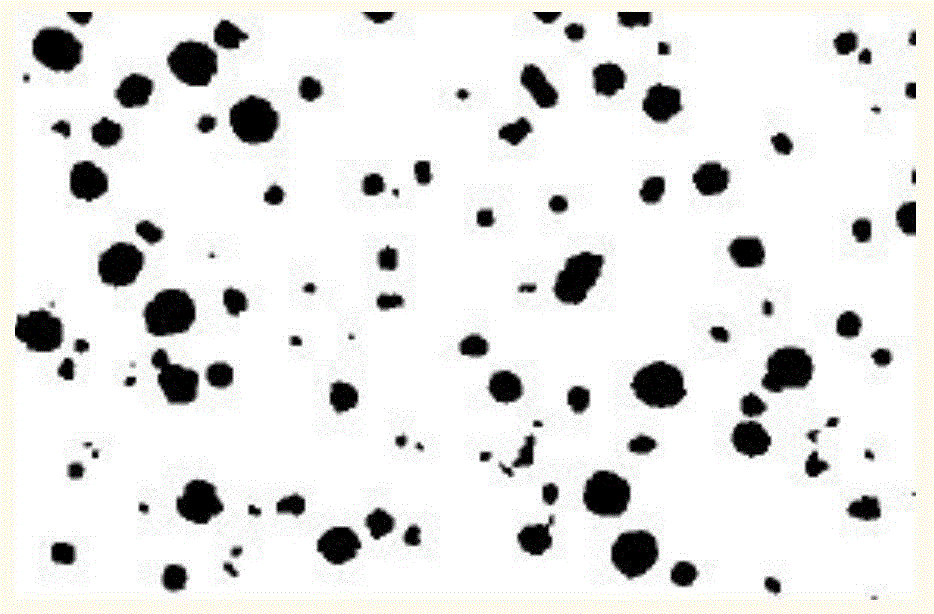

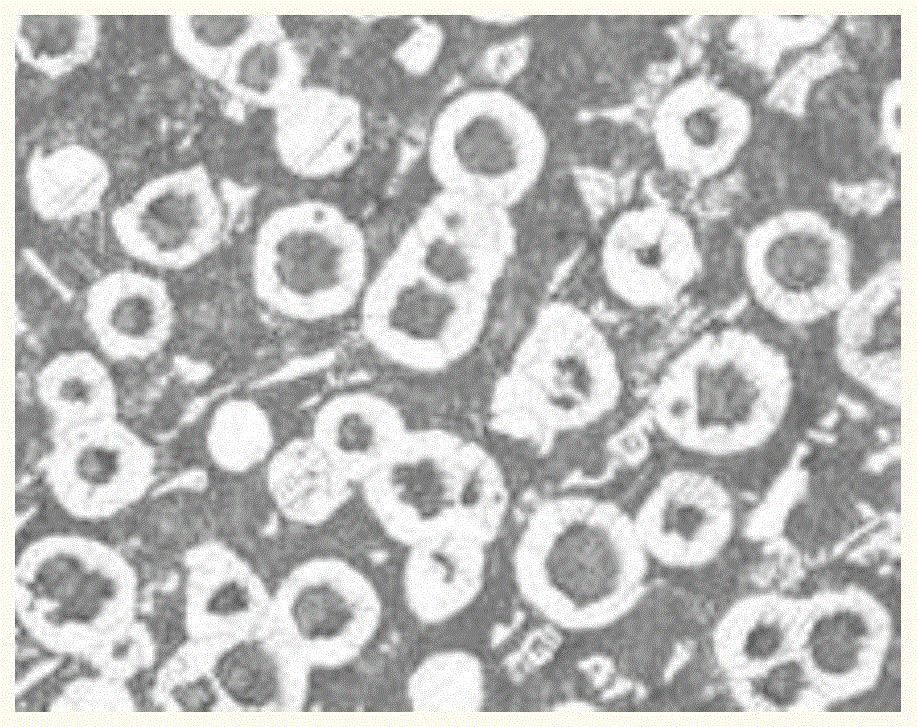

Embodiment 1

[0026] (1) First, put the raw materials of each component in the following proportions: 3.6-3.9% carbon, 2.5-2.8% silicon, 0.3-0.5% manganese, and the balance is iron" molten iron into the melting furnace and heated to 1550-1570°C Melting to obtain molten iron; then adding the molten iron into the ladle of the wire feeding spheroidizing device, covering the upper surface of the molten iron with 100-120mm thick glass, and the amount of glass added is 0.8% of the total amount of molten iron;

[0027] (2) Gradually pull the magnesium wire in the wire feeding spheroidizing device into the molten iron in the ladle of step (1) to carry out the spheroidizing reaction; the wire feeding speed of the magnesium wire is 120m / min, and the total wire feeding speed of the magnesium wire The amount is 0.8% of the total amount of molten iron; the magnesium wire reacts with the molten iron, the molten iron rolls violently, the glass melts to form a layer of slag layer, which floats on the surfac...

Embodiment 2

[0028] (1) Firstly, put the raw materials of each component in the following proportions: carbon 3.6-3.9%, silicon 2.5-2.8%, manganese 0.3-0.5%, and the balance is "iron" molten iron; put it into the smelting furnace and heat it to 1550-1570 Melt at ℃ to obtain molten iron; then add the molten iron into the ladle of the wire feeding spheroidizing device, cover the upper surface of the molten iron with 100mm thick glass, and the amount of glass added is 0.7% of the total amount of molten iron;

[0029] (2) Gradually pull the magnesium wire in the wire feeding spheroidizing device into the molten iron in the ladle of step (1) to carry out the spheroidizing reaction; the wire feeding speed of the magnesium wire is 100m / min, and the wire feeding of the magnesium wire is total The amount is 0.7% of the total amount of molten iron; the magnesium wire reacts with the molten iron, the molten iron rolls violently, and the glass melts to form a layer of slag layer, which floats on the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com