A fast circle cutting method for CNC laser cutting machine

A CNC laser and cutting machine technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems that large flat plates cannot be placed horizontally, the processing efficiency of machine tools is reduced, and the cutting head is frequently raised and lowered, etc., to protect the human body Healthy, small mechanical vibration, and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

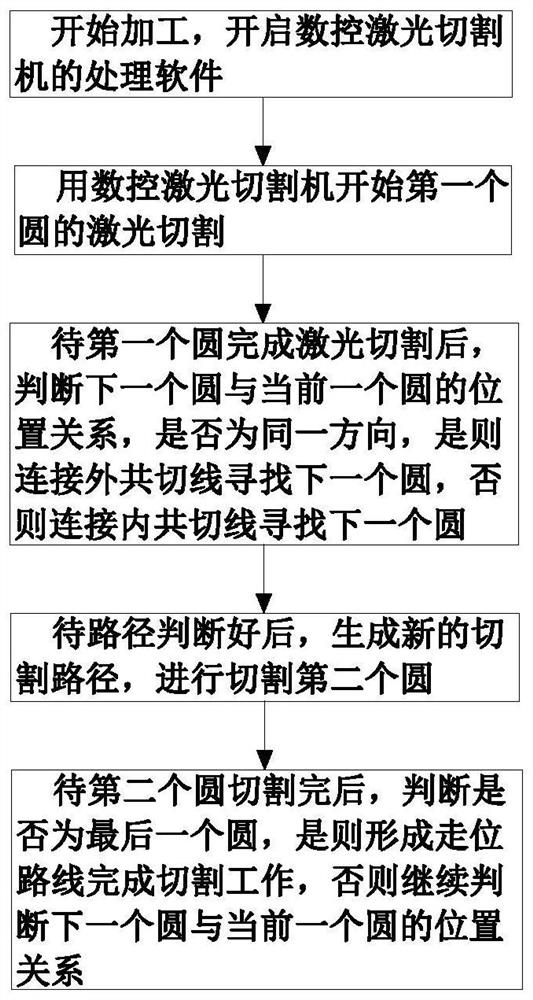

[0033] use Figure 1 to Figure 8 A fast circle cutting method for a numerically controlled laser cutting machine of the present invention is described as follows.

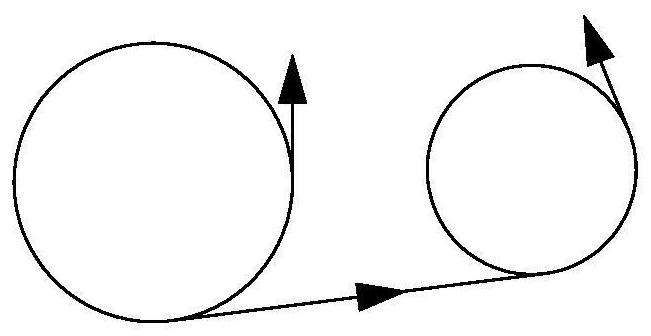

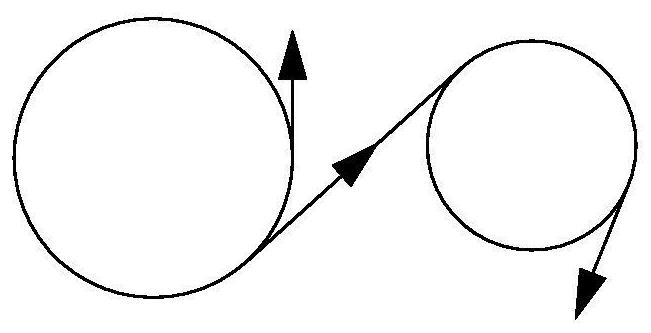

[0034] Such as Figure 1 to Figure 4 As shown, a kind of CNC laser cutting machine fast circle cutting method described in the present invention includes computer-controlled CNC laser cutting machine processing software for arc cutting, and the circle cutting method includes the following steps:

[0035] Step 1: Start processing and start the processing software of the CNC laser cutting machine;

[0036] Step 2: After the processing software is opened in step 1, start the laser cutting of the first circle with the CNC laser cutting machine; before the cutting circle of the laser head 4 reaches the corresponding circular path, the motor 11 drives the lead screw 12 to rotate, Make the slider 14 move on the lead screw 12, and move the slider 14 to the support guide rail 2 by controlling the motor one 11, and the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com