Hydraulic automobile co-pilot brake device

A brake device and hydraulic technology, applied in the field of automobile brake devices, can solve the problems of difficulty in adapting to different models, large frictional resistance, damage to the car body, etc., and achieve the effects of convenient disassembly and assembly, small occupied space and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the embodiment of the present invention is described further:

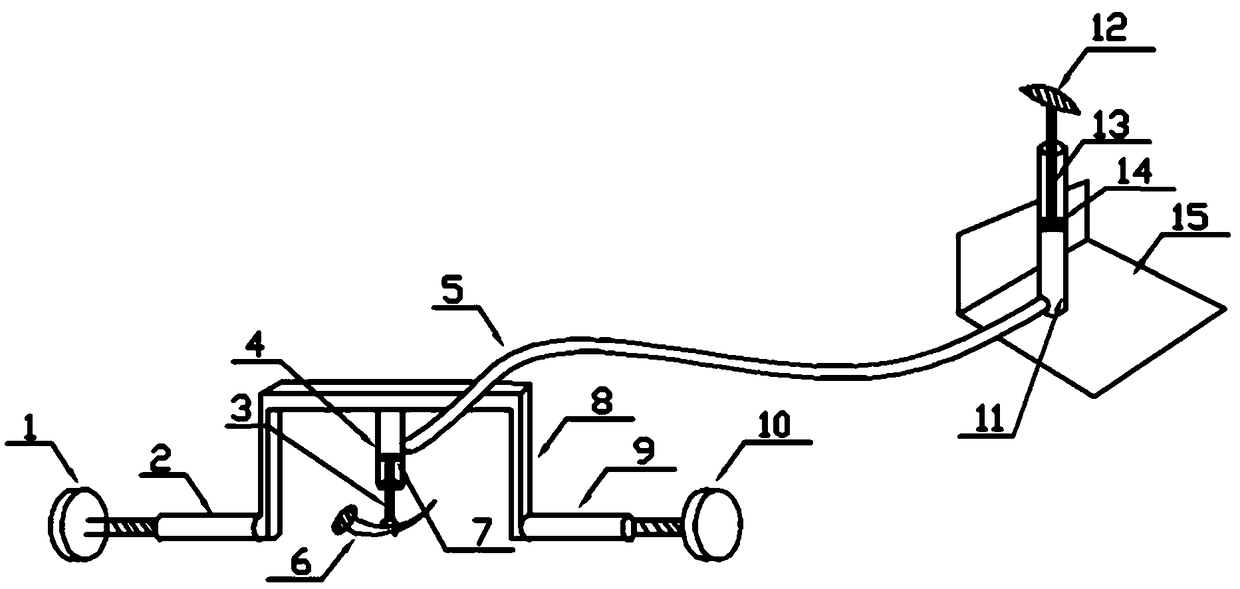

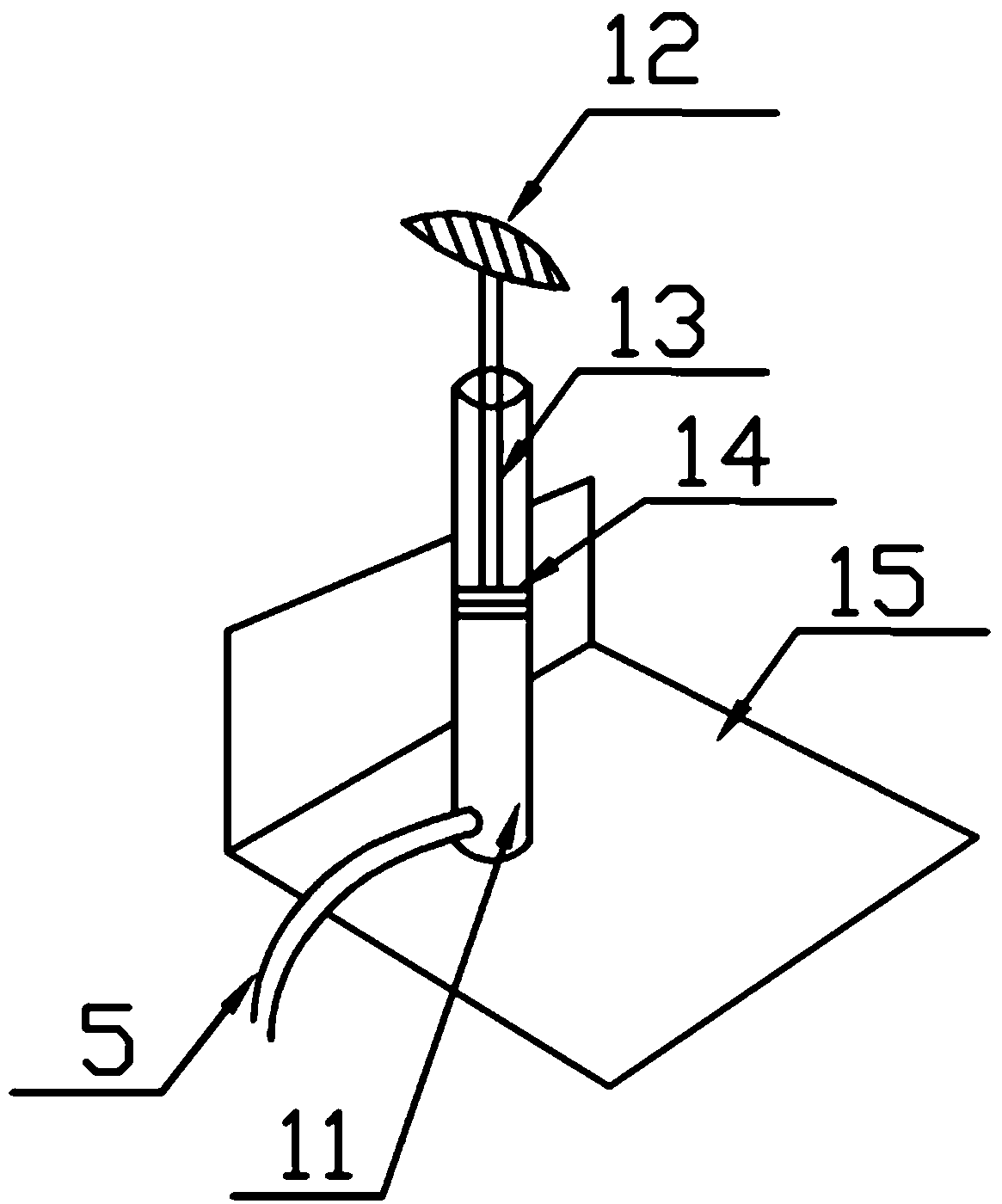

[0021] like figure 1 As shown, a hydraulic vehicle co-pilot brake device according to the present invention includes a main driver part, a co-pilot part, and an infusion tube; Before, the infusion tube 5 is connected with the main driving part and the copilot part.

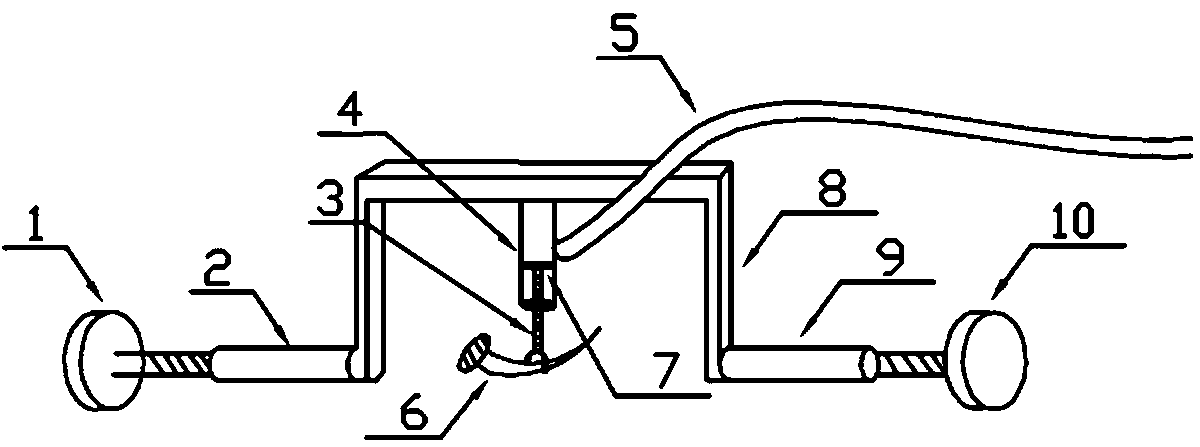

[0022] refer to figure 2 , the main driving parts include a first support bolt 1, a first sleeve 2, a fork lever 3, a first hydraulic cylinder 4, a first piston 7, a convex frame 8, a second sleeve 9, and a second support bolt 10 . Wherein, both the first sleeve and the second sleeve 9 have internal threads, and the first support bolt 1 and the second support bolt 10 are respectively screwed into the corresponding sleeves, and the heads of the two support bolts are flat and the end faces are rough, so they can be screwed with a wrench or Manually rotate to change the length of the two bolts p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com