Automatic gasket absorbing system for gasket machine

An adsorption system and gasket technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of manual transmission, poor practicability, and the inability of the gasket machine to automatically absorb gaskets, etc., to save manpower and manual push, improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

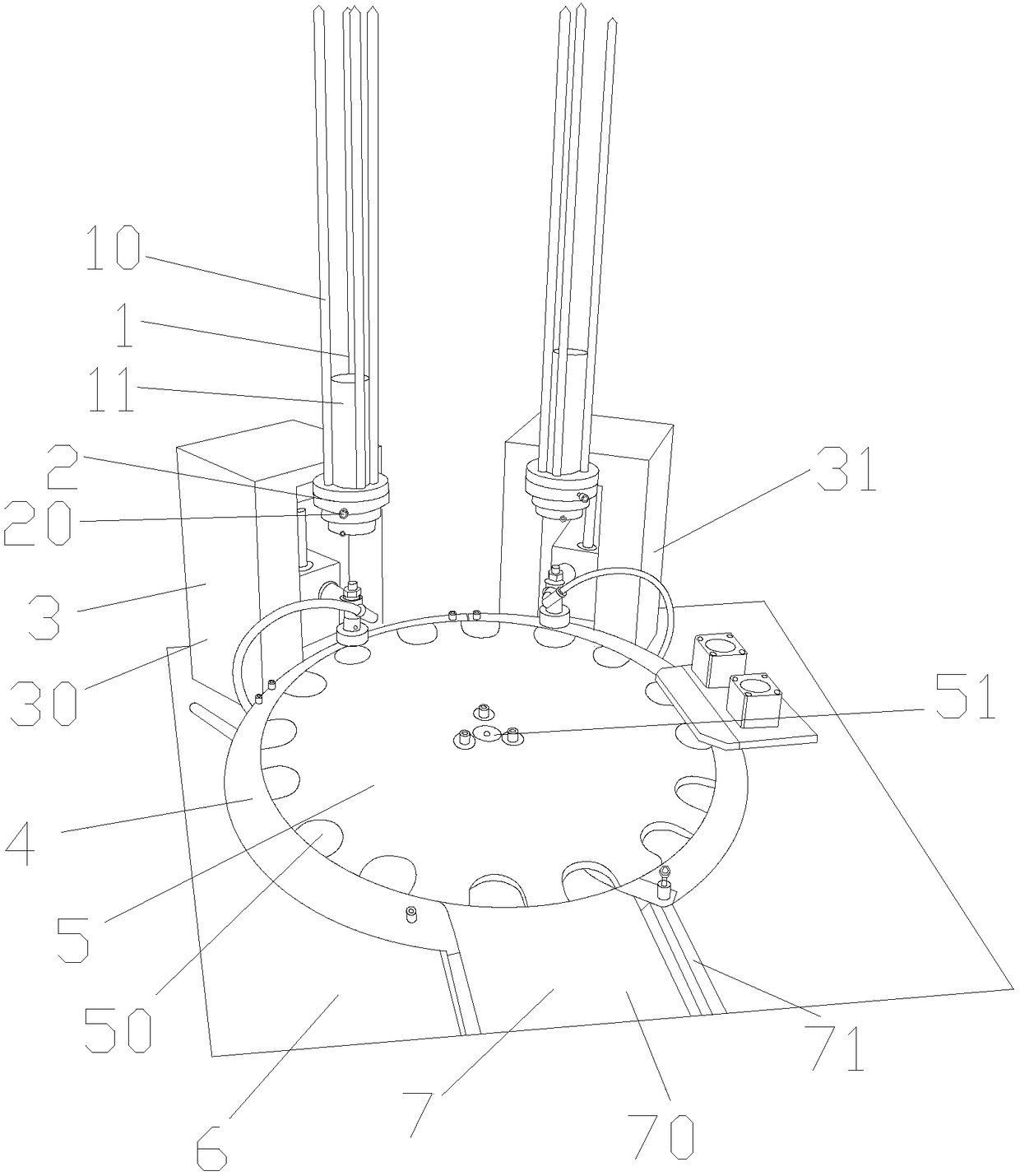

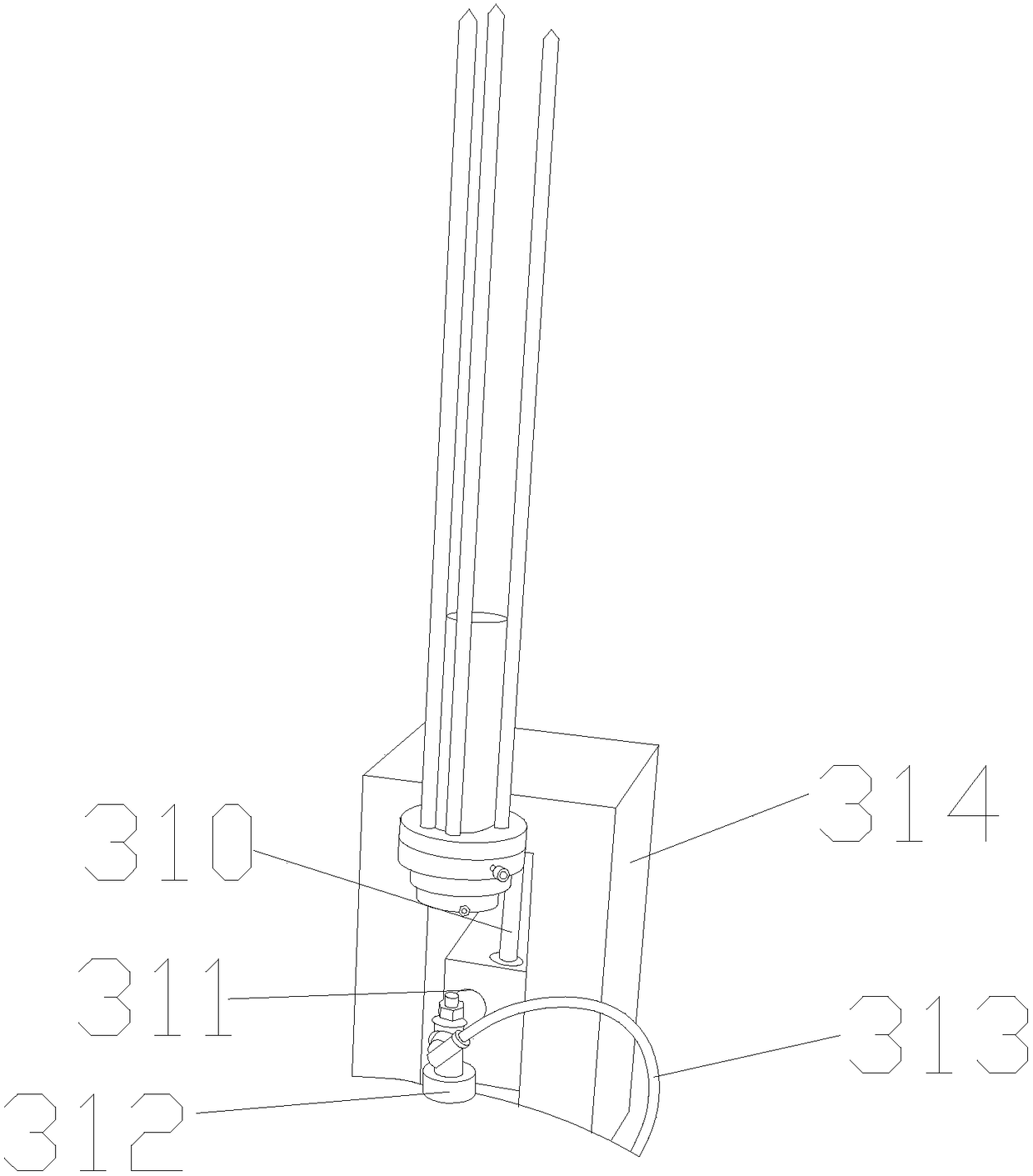

[0018] see Figure 1-Figure 2 , the present invention provides a solution for an automatic gasket adsorption system for a gasket machine: its structure includes a gasket storage tank (1), a bracket seat (2), an adsorption device (3), a rotating fixed ring (4), Disk drive (5), workbench (6), transmission system (7), the gasket storage tank (1) is arranged above the support seat (2), and the support seat (2) is arranged on the adsorption device (3) Above, the adsorption device (3) is arranged behind the disk fixed ring (4), and the disk fixed ring (4) is arranged on the outside of the disk (5), and the disk (5) is arranged on the workbench ( 6) above, the workbench (6) is located below the conveying system (7), the gasket storage tank (1) is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com